So you thought Design Validation was difficult?

May be its

time we put design validation into perspective! How about considering it as a

mainstream tool meant for every designer? Skeptics or Analysts might argue,

assuming everyone is qualified enough, could be a dangerous proposition! Ask

them; what are the tools that a designer relies upon? Three things I believe …

1. Legacy

data available in an organization.

2. Hand

calculations.

3. Design Intuition.

While these

are very effective, is it safe enough to assume all parameters that affect a

design were considered? If the answer was positive, Design Validation as a

field would never have evolved.

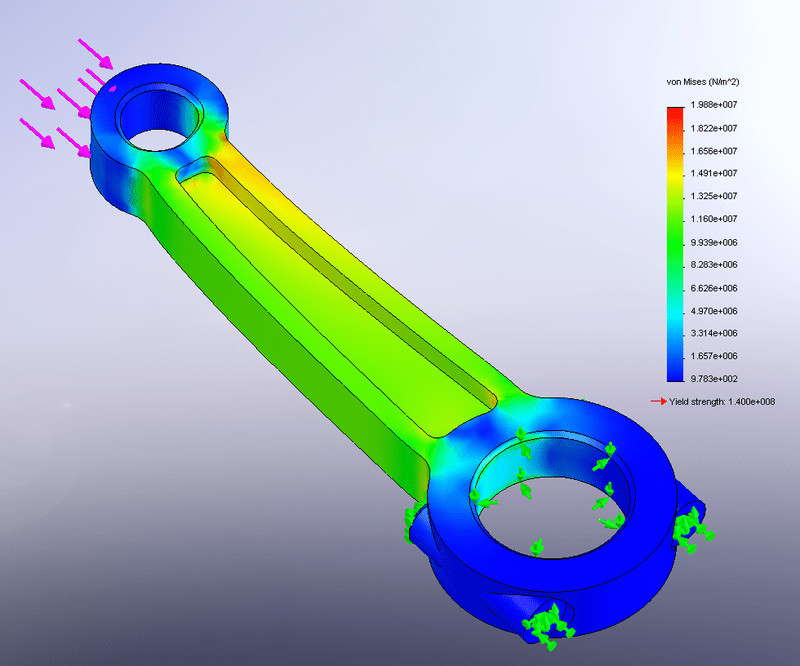

Modern day

computer algorithms help us consider multiple design scenarios quickly and

efficiently. Thus making virtual testing

a great tool, helping us save, time and money. Solid Works Simulation or COSMOS

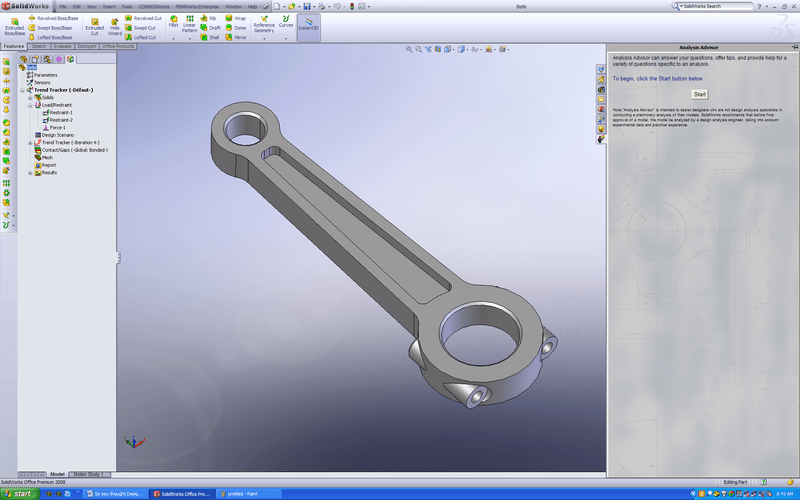

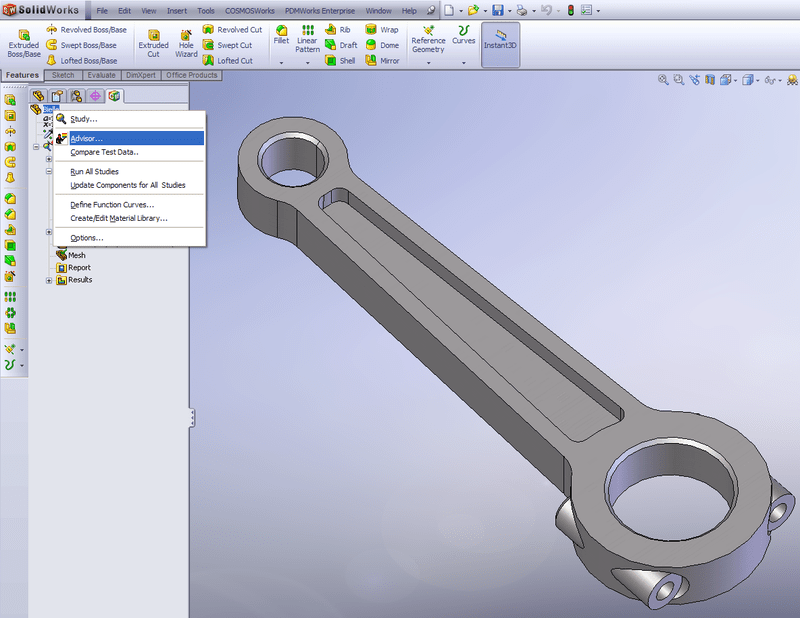

is one such tool. Tools such as

“Analysis Advisor” guide through the process of testing. It more or less acts

as a GPS, helping us crank the most out of our conceptual designs. So how do I use this?

Once you have

a 3D model of your design; click on COSMOS Analysis Manager Tab. Right click on

the name of part or assembly file. From the fly out tree, click on “Advisor”.

On your right hand side you will be greeted by Analysis Advisor Start

button. On the tab, it says “Analysis

Advisor can answer your questions, offer tips, and provide help for a variety

of questions specific to an analysis.

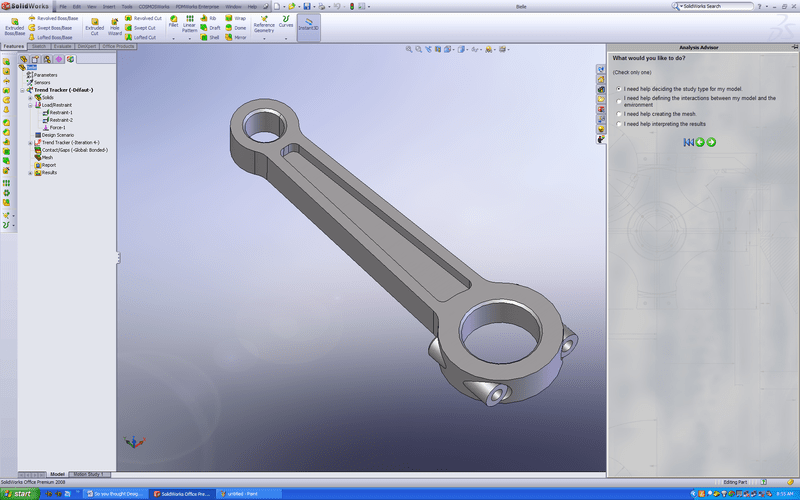

The next tab (“What

would you like to do?”), asks you questions to help guide your design

analysis. Let’s say you need help on the

type of test that needs to be run. Your

final goal is to understand, if this design would deform too much or what would

it take to break it. Go to the next tab, using the arrow keys.

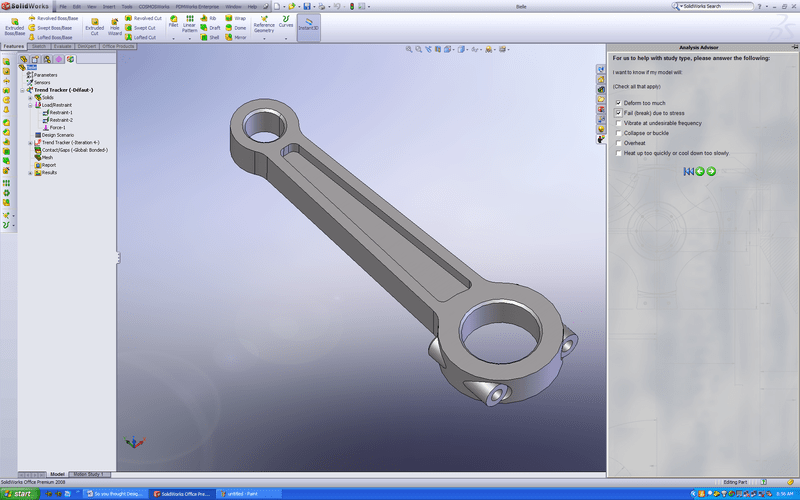

Analysis

Advisor then tells you what type of conditions would lead to such a failure.

You then need to tell the software how is the component loaded? How does it

interact with other components in your design? The last tab asks you to select,

the type of material being used. By answering these questions software knows so

you are interested in.…

- How much does the component deform?

- What does it take to break it?

- What material are you using?

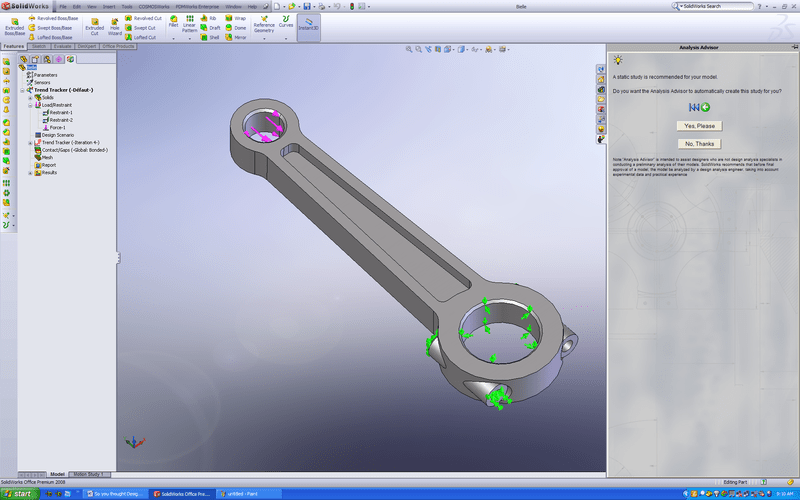

Based on this

the software recommends a static study for your design. You can then start the process all over

again, and take help in setting up the model for a test.

So you see it

doesn’t take an expert to run a test. All you need is an understanding of how a

design interacts with its environment. That’s just common sense!

Rajat Trehan

Product

Manager – Design Validation

Computer

Aided Technology Inc.

Blog

Blog