Static Weldment Analysis

Anyone who has come across the dilemma of sizing welds has

wondered if FEA can help? So why is that no software on the market claims to

have perfected this art so pertinent to manufacturing industry.

FEA with all its calculative functionalities has certain

whims that need to be precisely catered to. FEA prefers all parts are gravity

cast blanks with polished surfaces free of any imperfections. Moreover, FEA

assumes all structures are heat treated to remove any residual stresses. The

manufacturing process in itself should be numerically controlled. All these

assumptions are obvious to produce consistent and predictable part to part

performance.

Weldments on the other hand never have any sort of

consistency. They vary due to change in temperature, chemistry of weld beads,

chemistry of base materials, weld geometry, residual stresses etc. Hence many

consider sizing welds an art and often end up with under-sized or over sized

welds. Anyone who has actually attempted in sizing welds using FEA has observed

several “hot spots” or stress singularities at the transition from weld bead to

geometry. One obvious question then arises are these stresses controlling? What

values have to be taken into consideration?

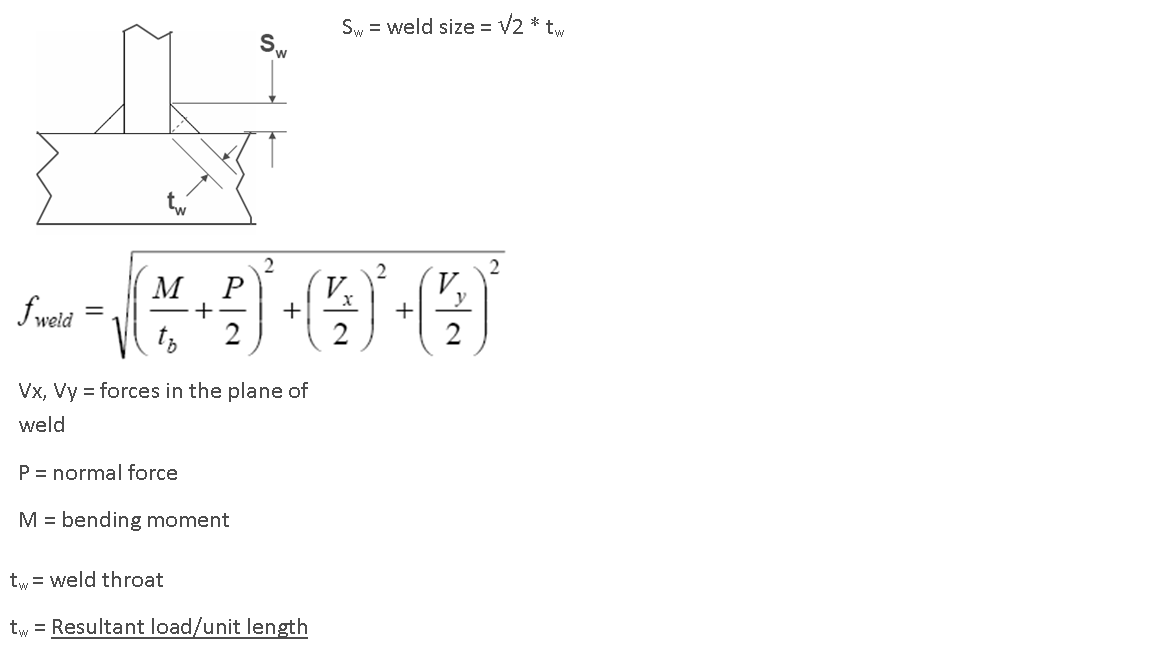

Throat Shear Method

The Throat shear method eliminates the need to estimate

initial weld size. This method accounts for allowable strength per unit length

in a weld based on weld type, and electrode used. These standard allowables are

based on physical tests and hence account for variability. Moreover obtaining

forces and moments from geometry are easy compared to stresses. Loads are less

sensitive to local geometry and mesh independent. So if you mesh a component

with three different mesh sizes, reaction loads from all three would be same,

unlike stresses, which would vary.

This methodology does not require you to model weld geometry

if using shell geometry. For solid models, there is some extra work required.

One can simply build mesh with welded parts intersecting.

In the areas you need to size welds, place split lines to

force evenly spaced vertices along the weld seam. Solve using draft quality

elements for boundary conditions applied. Extract forces at the vertices;

convert them into per unit loads. Compute weld size by dividing resultant load

by allowable strength. Allowable can be obtained using standards AWS D 1.1.

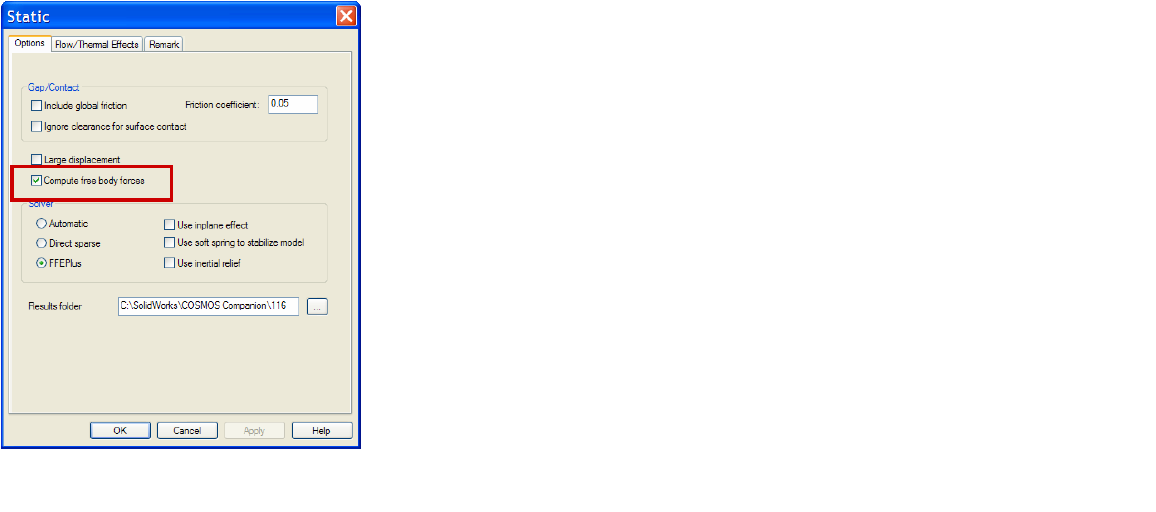

Force values are easily available if “Compute Free Body Forces” option is

checked under study properties. FBD forces are available for vertices, edges,

faces in Solid works 2009.

Rajat Trehan

Product Manager – Design Validation

Computer Aided Technology Inc.

Blog

Blog