Modeling beyond the limitations

Let’s take a look at moving around a modeling roadblock. We

have all had a feature for whatever reason doesn’t work even though there seems

to be no reason why not. Some times SOLIDWORKS models may have issues that seem

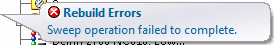

to be trivial, in this example there is an overlapping cut sweep that won’t calculate.

This message from SW was not helpful in any means:

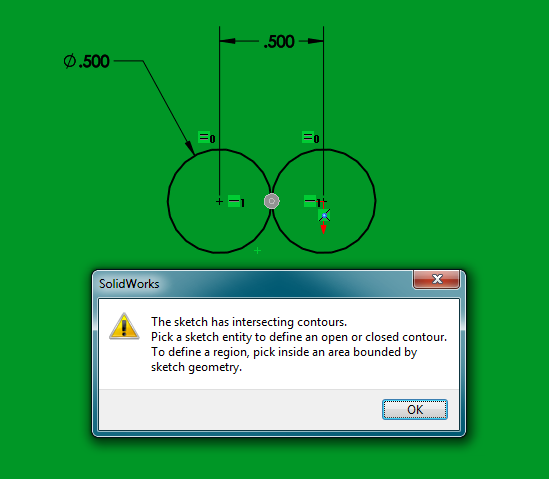

The underlying issue here is that at some point the profiles

overlap at an exact tangency. As many of you know that even putting two holes

into a part that touch at an exact point of tangency will have an error.

SOLIDWORKS can’t decide if there should or should not be material at that very

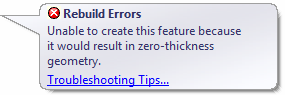

point. The result is a geometry error as seen here:

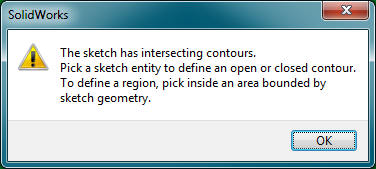

Or attempting with selected contours give this more familiar message:

So in this example we have the profile section changing

position along a helix that is changing pitch. This at a spot along the curve

will result in a tangency issue. Although the error message doesn’t tell us

what the error is, there is at least one way to still make this work knowing

what we do about the software.

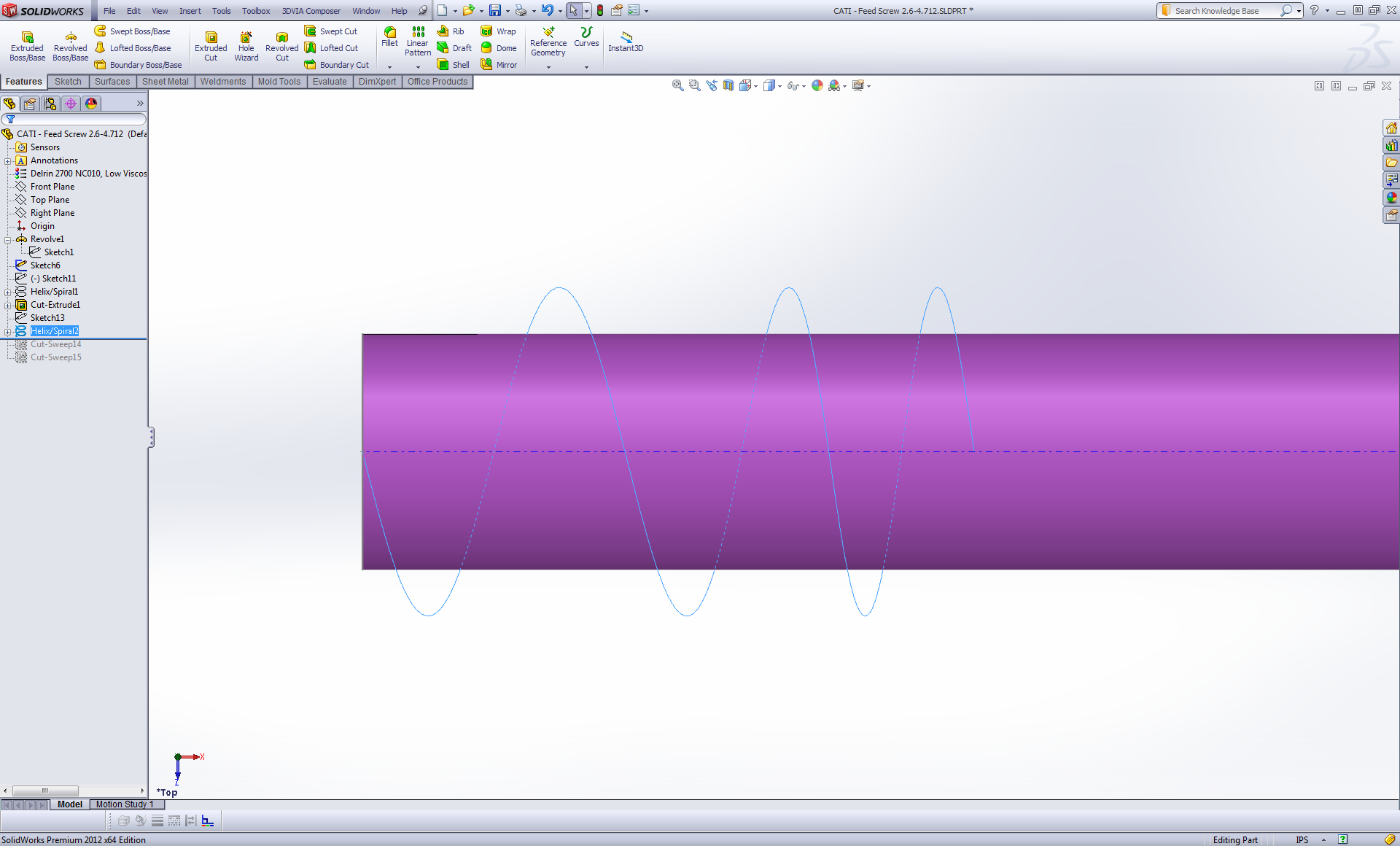

Here we take the initial helix and duplicate it.

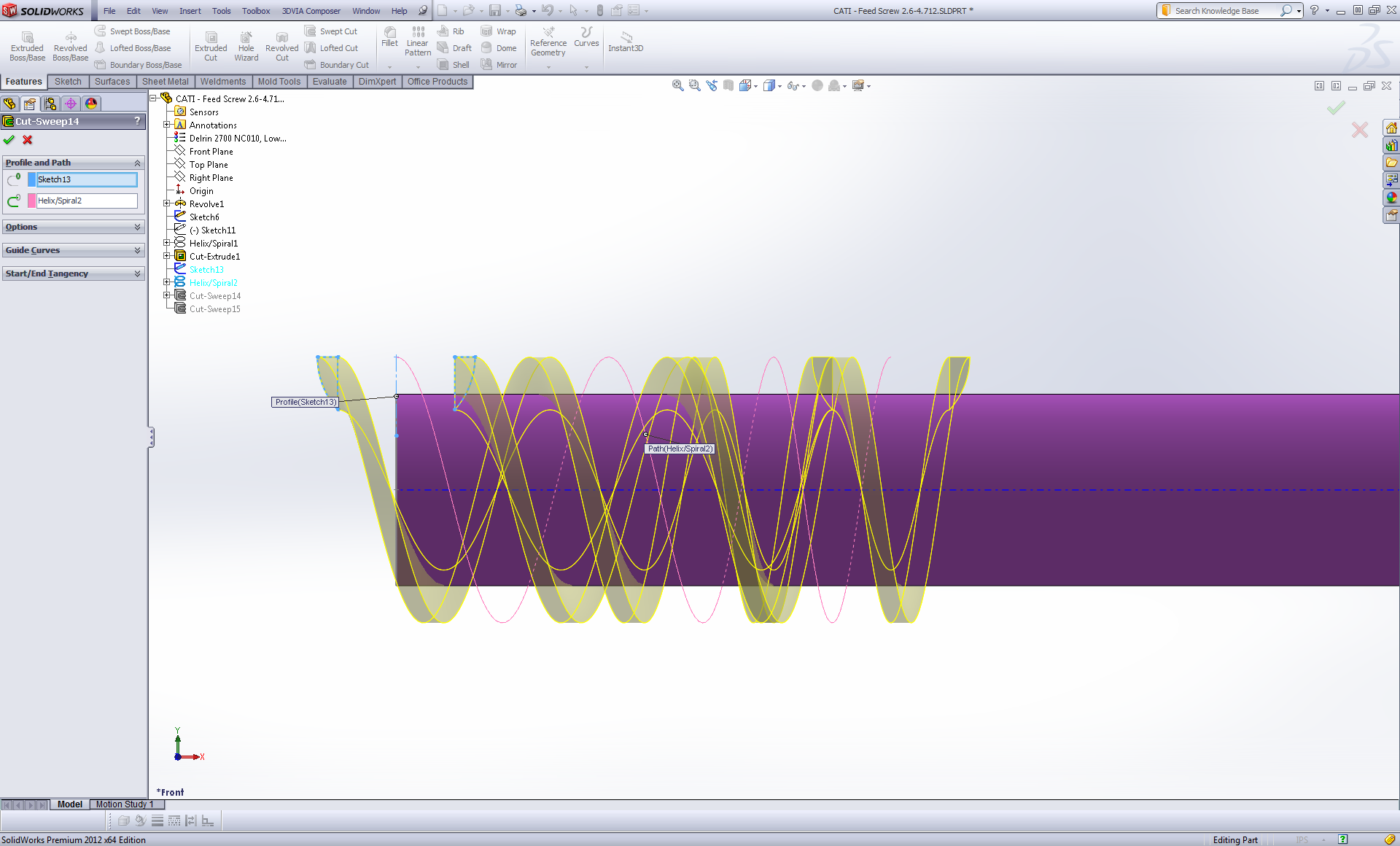

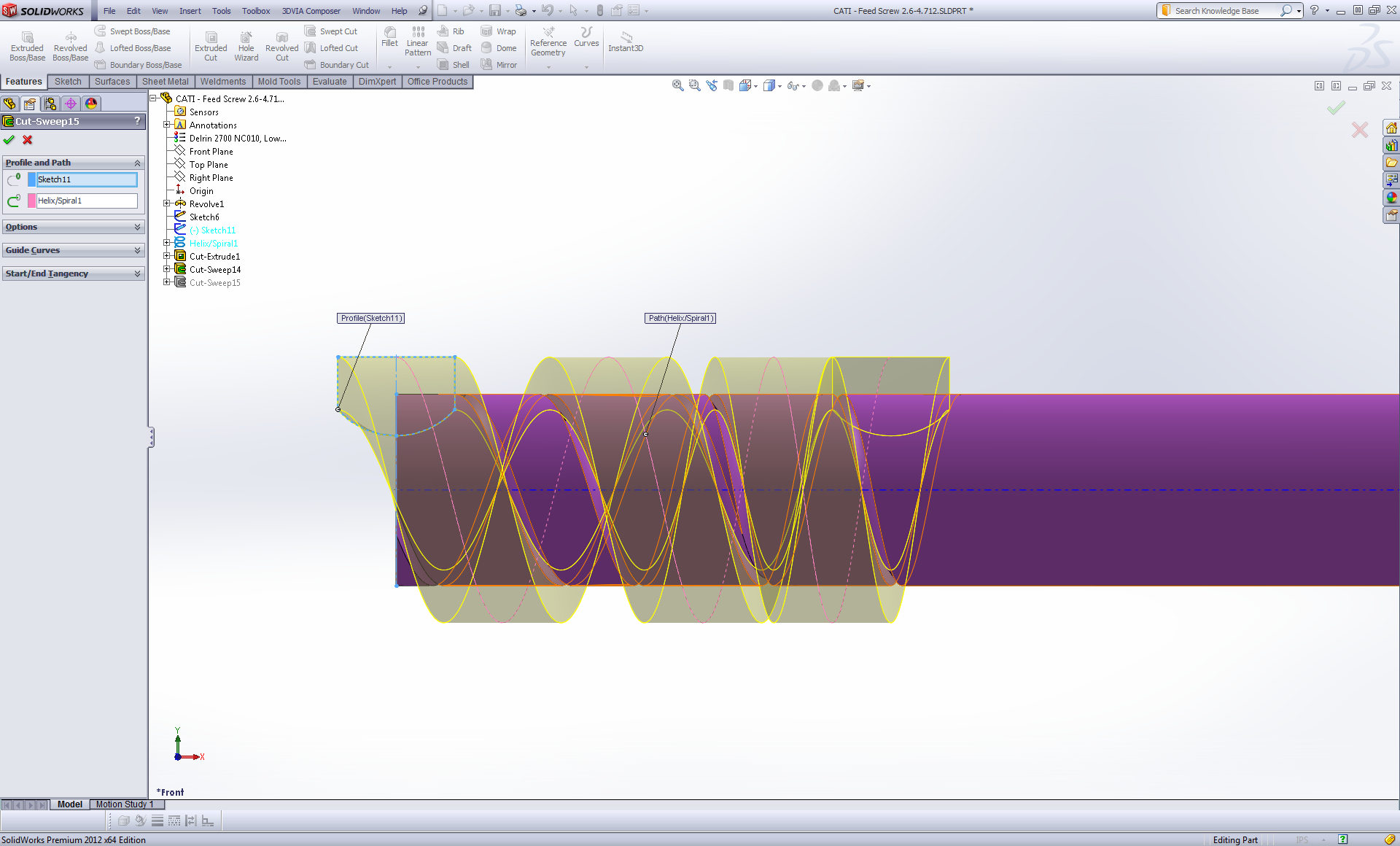

Then we duplicate the profile as well and split it into two

profile sketches that deal with only part of the cut at a time. SolidWorks

allows each cut to be created as separate features.

Even though they still touch, SOLIDWORKS doesn’t error because it is only dealing with

one cut at a time and doesn’t create a geometry calculation issue with

self-intersecting passes.

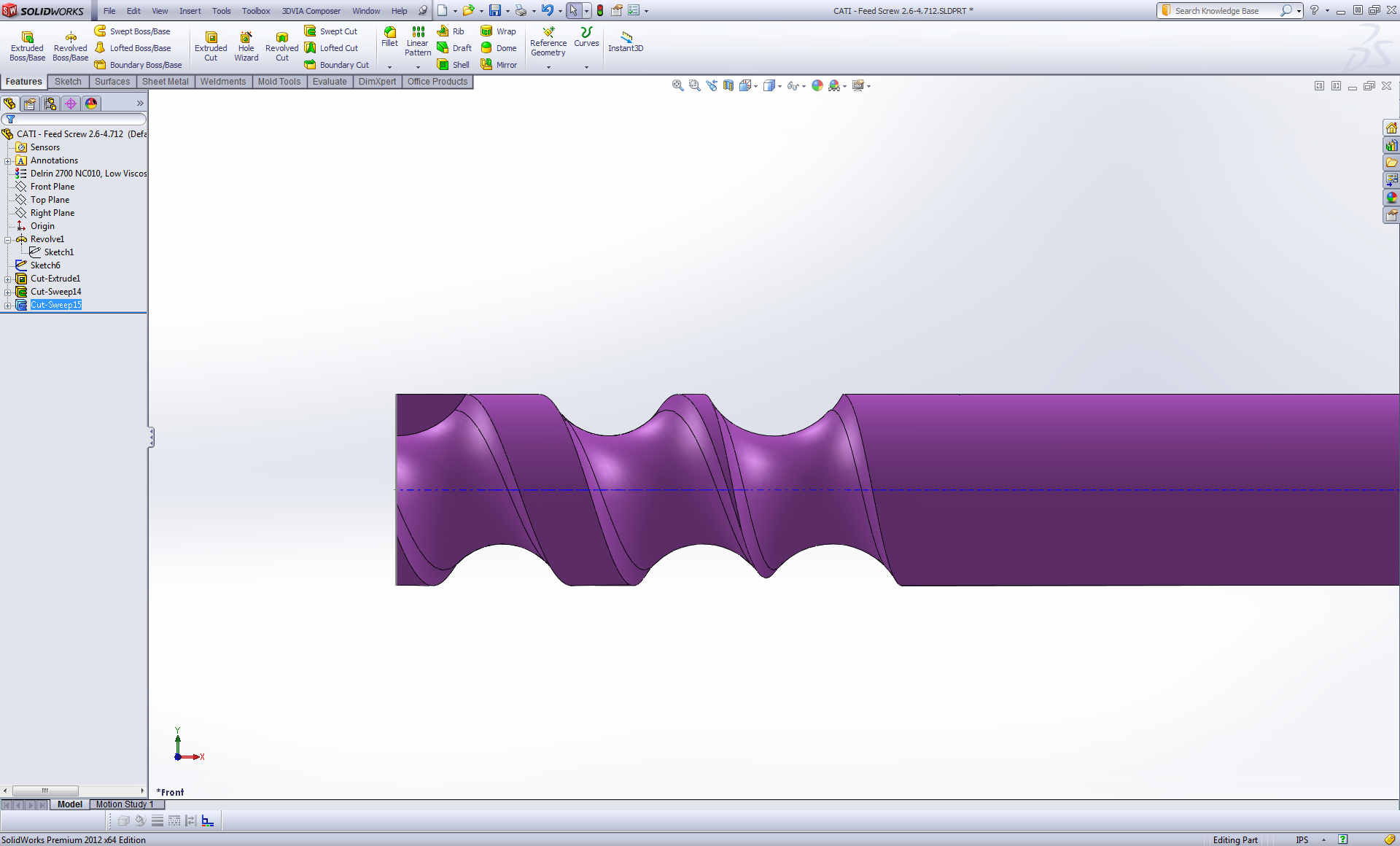

Finished results:

I am sure there are other solutions but this is not too painful to figure out.

John Van Engen

CATI Tech Support

Blog

Blog