Creaform 3D Scanning: PLM Process

3D Scanning in the PLM Process

Information in this article was originally published by Creaform in the eBook, An Introduction to 3D Scanning.

3D scanning has emerged as a critical tool in every step of the product lifecycle management (PLM) process. This is especially true of the new generation of truly portable, self-positioning scanners.

The ability of 3D Scanners to bridge the gap between physical objects in the real world and the digital de-sign environment has become extremely valuable in a wide range of industries that use PLM — aerospace, automotive, consumer products, manufacturing, and heavy industries among the principal ones.

These industries benefit from faster time to market, improved quality, reduced warehousing costs, and better understanding of product performance.

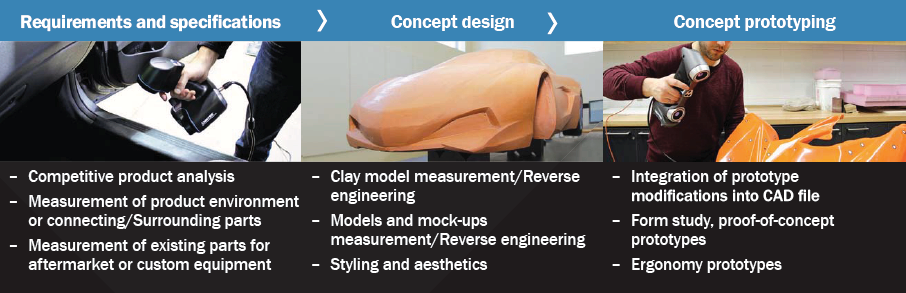

3D scanning is used in the concept stage of PLM for a wide variety of processes, including determining requirements and specifications, concept design (including reverse engineering) and concept prototyping.

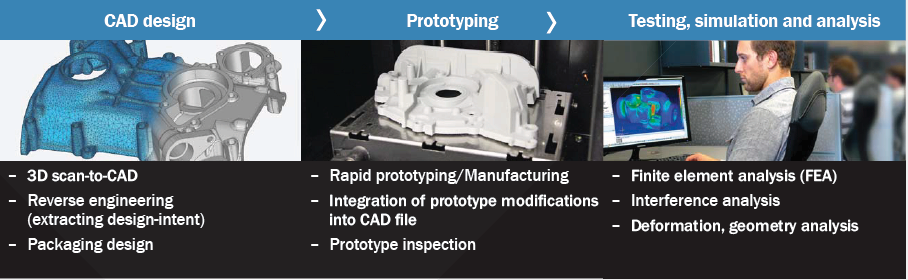

3D scanning is used in the design stage of PLM for computer-aided design (CAD); rapid prototyping; and testing, simulation and analysis (CFD, FEA).

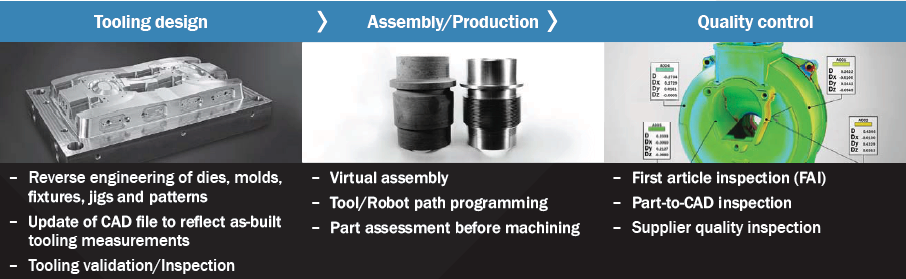

3D scanning is used in the manufacturing stage of PLM for applications such as tooling design, assembly and production, and quality control.

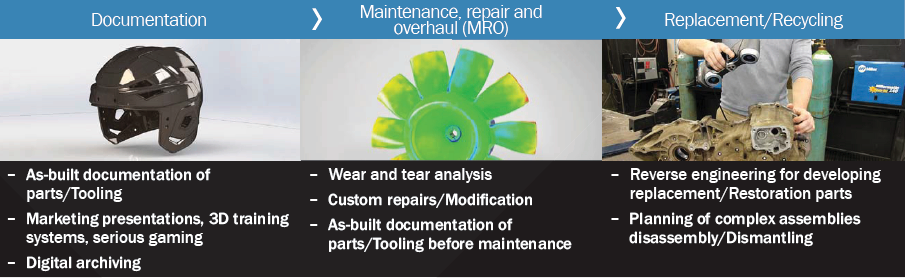

3D scanning is used in the servicing stage of PLM for applications such as documentation; maintenance, repair and overhaul (MRO); and replacement, recycling and restoration of parts.

In future articles, I’ll publish more excerpts from the Creaform eBook – An Introduction to 3D Scanning.

In the meantime, you can download An Introduction to 3D Scanning.

Jim TeDesco

Director, Marketing

Computer Aided Technology

Blog

Blog