SOLIDWORKS: Using Hardware Kits for Hardware

Using Hardware Kits for Hardware

Why is my assembly so slow in SOLIDWORKS? Let’s continue on this idea that’s been started by Bryan Pawlak. As mentioned previously, there are many things that effect performance in an assembly that are modeling related. Today we are going to take a look at mates, particularly with hardware.

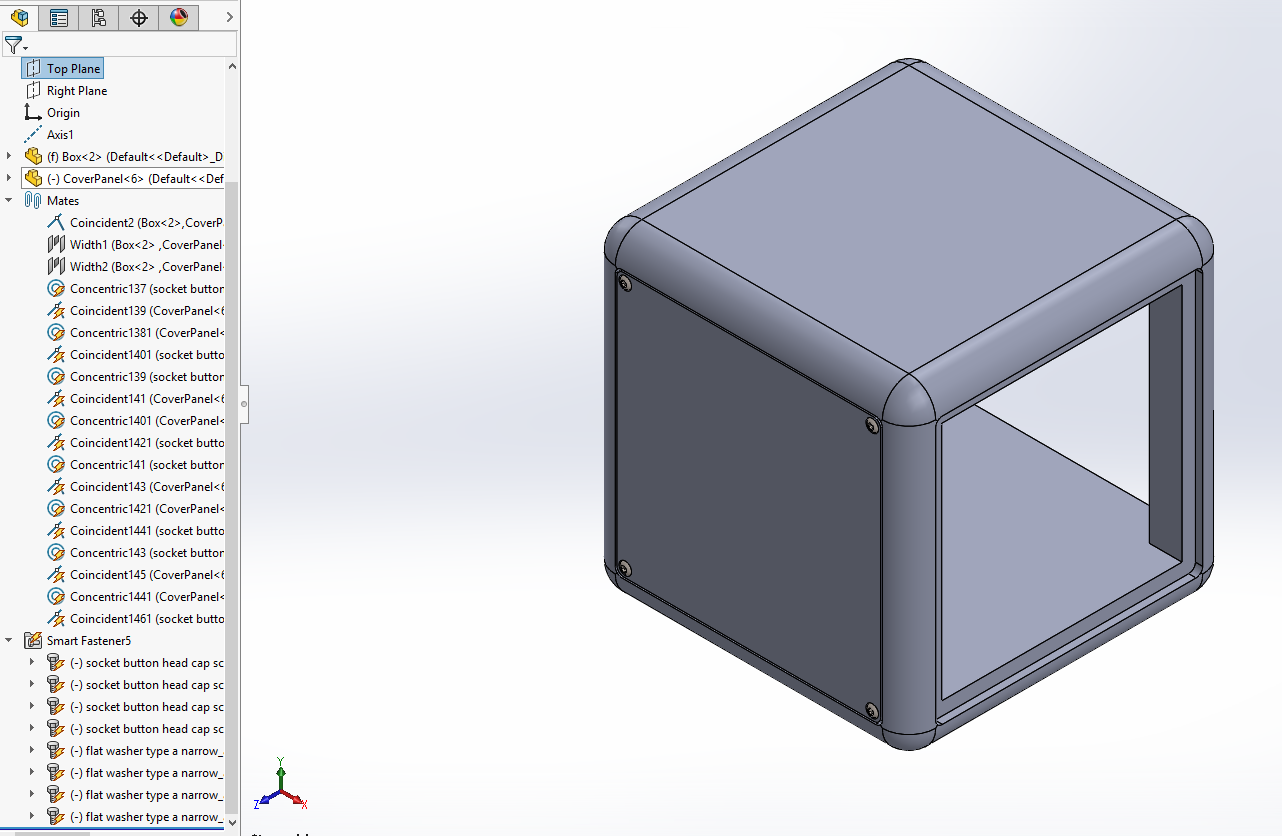

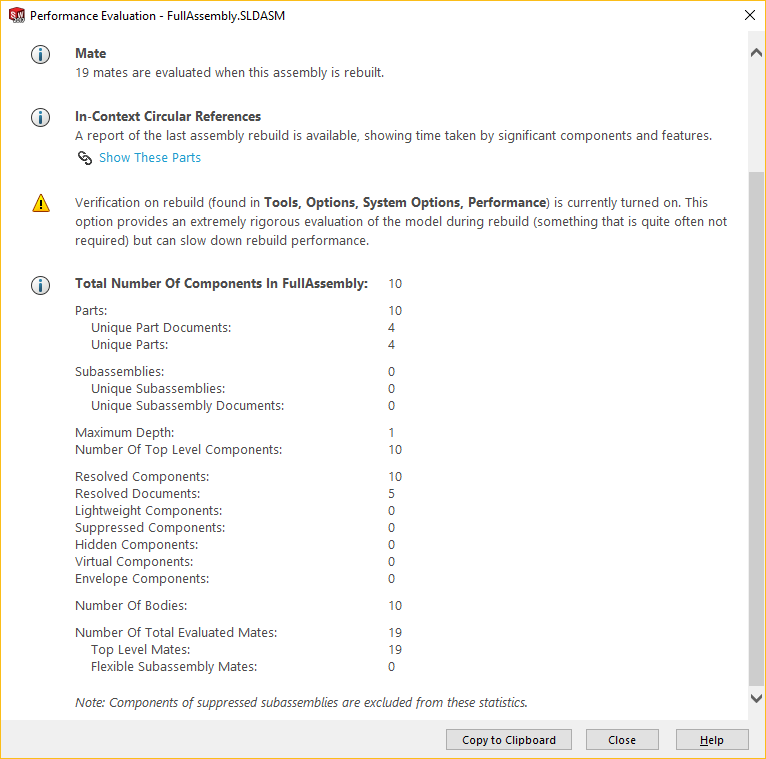

I’ve created a sample box, with a screw on cover. I used Smart Fasteners to drop in 4 Socket Button Head Cap Screws and washers. This brings the total number of mates up to 19 that get evaluated when the assembly is evaluated.

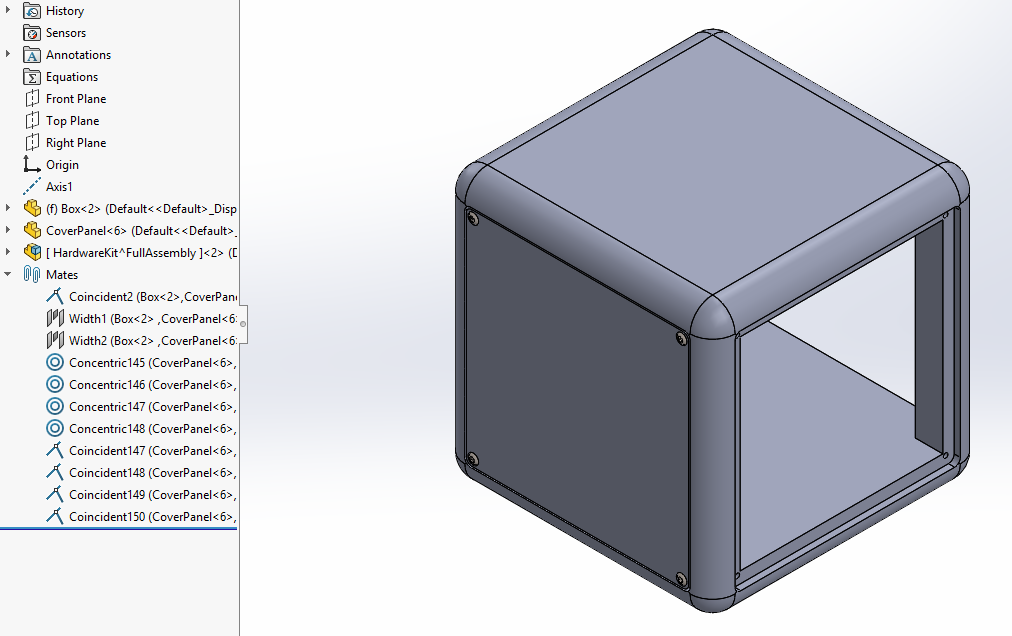

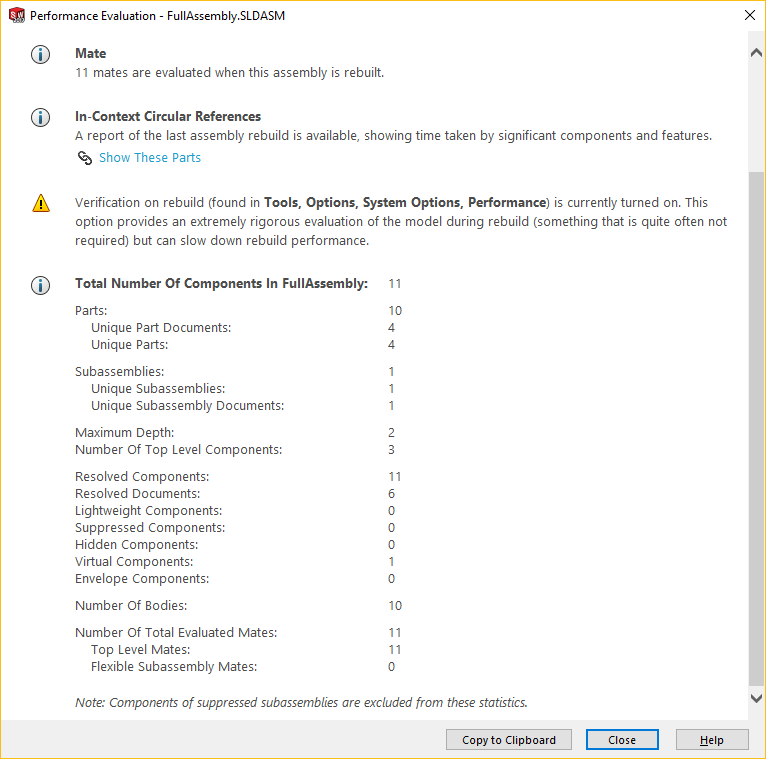

On the whole this isn’t too bad, but with larger assemblies, this number can grow. All top-level mates get evaluated simultaneously when the assembly is being rebuilt. One thing that can help with performance is utilizing ‘hardware kits’. This is basically a sub-assembly with all of your hardware in it. You can take your hardware and use the option ‘Form New Sub-Assembly here’ to push all of the hardware into a separate assembly. In the case of my simple assembly, half of the mates went into the sub-assembly while half of them stayed behind.

This now reduces the number of mates being calculated down to 11 from 19. In addition, this gives you a hardware kit assembly that you can call out as a single item in your Bill of Material, and have a separate list for. Depending on what you’re working on and how your shop works, this can simplify pulling hardware for assemblies, packaging hardware. This also allows you to create a simplified configuration of your assembly with the hardware suppressed for use further downstream. Simplifying hardware to only where it’s needed can help speed up larger assemblies by minimizing the detail that has to get rendered to the screen and calculated.

Fred Zobel

Sr. Technical Support

Computer Aided Technology

Blog

Blog