Does This Really Work? Flow Puts to Test "As Seen On TV" Design

Recently I was up late with my sick child trying to keep his fever down. To keep myself awake for the next thermometer reading, I decided to partake in some late night television. I ended up watching one of the popular sales channels known for its Quality Value and Convenience. Why I do not know, but that is where I ended up. The clearance deal that they were selling at that moment peaked my interest.

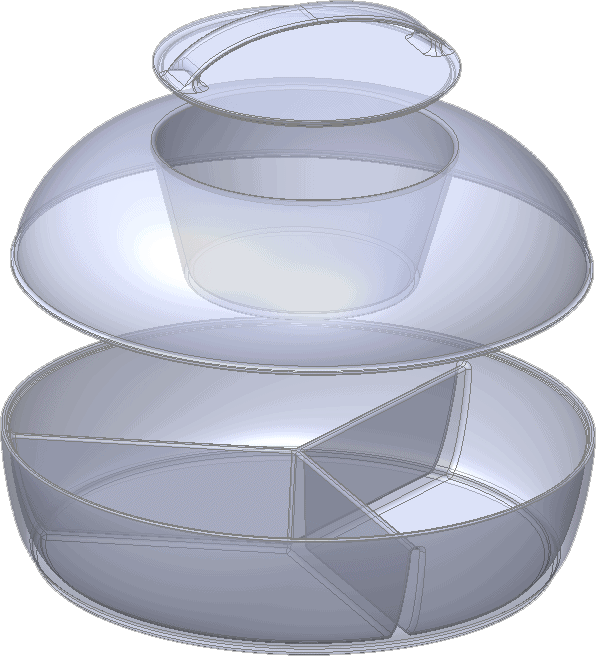

The “Iced Up Appetizer on Ice Divided Platter with Locking Lid” is a plastic appetizer tray that has a dome lid. Nothing special there until they explained what the “bowl” that was incorporated in the lid was for. It was for Ice. Yep this was a cooling appetizer tray that used Ice to keep your fruit, veggies, and cheese from getting hot. After watching the presentation I had my doubts as to if this would really work. Specifically that plastic is an insulator, the tray primarily uses natural convection as its mode of heat transfer, and the description of the product got me thinking.

The online description states: “The clip-on domed lid includes an ice chamber that allows cold air to descend upon your food, keeping it fresh and chilled for hours.” Thermodynamics here we come!

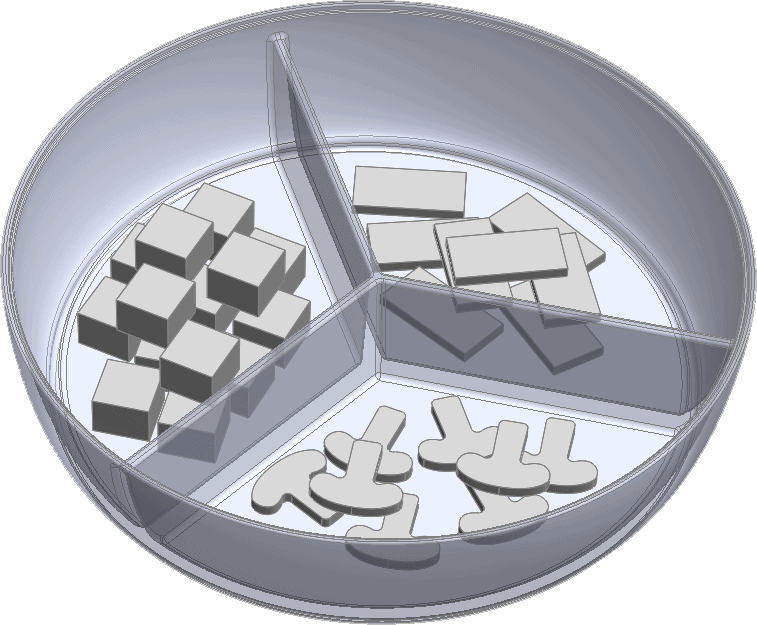

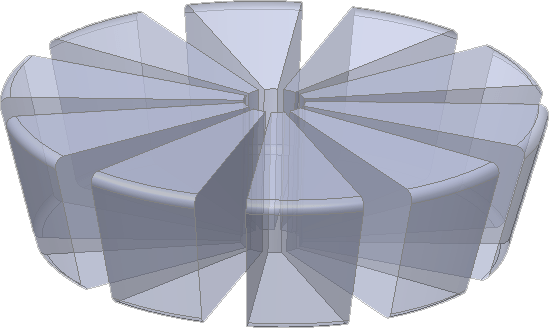

My wife would not let me spend the 20 dollars to test this contraption, so I turned to SOLIDWORKS Flow Simulation to get a feel for its performance. First step was to model the tray as accurately as possible. Using dimensions from the sellers website I was able to model a representation of the tray. I used polycarbonate for the tray material as this is the closest to the material stated in the demonstration. I also added cheese slices, fruit cubes, and veggies in the tray to add to the realism of the simulation. I was able to get the material properties for the food online. I used an average value for each type of food to better represent how most foods in this category would behave. The ice was modeled to have as much contact with the bowl as possible and patterned making a full bowl..

I ran two studies to best capture the behavior of the design. A Transient analysis set for 20 minutes was used to see how the temperature increased or decreased in the domain. The second was a Steady State study used for verification of the Transient. The ice is held at a constant 0 degrees F for both simulations giving the tray an advantage over real world conditions where the ice woudl normally melt and increase in temperature. The food was given an initial temperature of 34 degrees F to mimic being taken from a refrigerator and placed in the tray. The tray and ambient surroundings start at a temperature of 72 degrees F typical of a mild Ohio summer day.

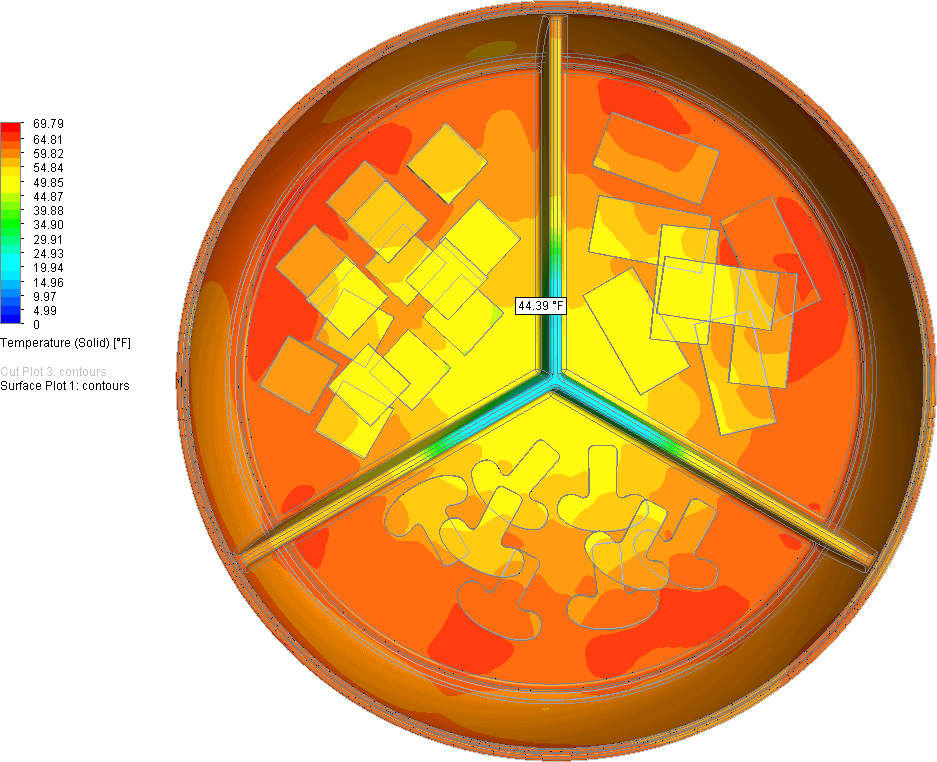

The cold air does descend as stated by the host, but what you see in the animation below is that the cold air at the end of 20 minutes only chills the center of the tray. Furthermore the air is only chilled to a lowest temperature of 41 degrees F directly below the ice chamber. Again this is with the Ice keeping at a constant 0 degrees F. This means the food would need to be clustered directly below the ice bowl and not spread out in the tray to stay cool.

A section plot directly below the bowl shows the cool are is clustered in columns of cool air as well. The surface plot of the food also shows that the further away from the center the warmer the food woudl be.

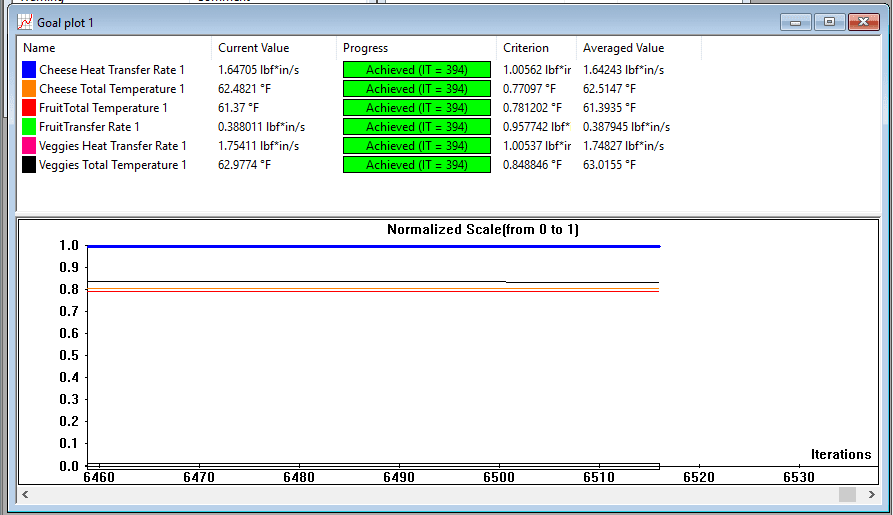

The transient study after 15 minutes physical time showed convergence for the temperature goals. This lead me to the conclusion that beyond 15 minutes there woudl be little if no change in the temperature, keeping in mind no changes to the ice temperature. To verify the convergence I completed a Steady State analysis as well.

Steady State is a study were all variables being held the same, the solution would produce the same in 20 minutes or 2 hours. The Steady State solution showed similar results to the Transient study. You will notice the food is at a cooler temperature than that of the 20 minute cut off I chose. Note though that the temperature difference is marginal and the cool air is still clustered at the center of the tray.

With all the information above I still feel actually purchasing the tray and testing it would be interesting if not insightful. Due to variances in the material properties chosen for the Simulation to real world properties, there could be better performance in real life. I however think that the tray while it does partially what the description says in having cool air descend on the food, will have a hard time keeping your food cool (30s-40s range temperatures) for hours. I would propose that conduction is a much faster and efficient way of keeping the food cool. As a design option would be to use a metal bottom and a chamber for the ice below the bottom of the tray. This change would incorporate more condition for the heat transfer rather than convection. With this change I feel the food would stay cooler at a lower temperature longer. Maybe that is the next test for Flow.

Blog

Blog