How to Reduce 3D Print Build Time Part 3: Model Material as Support

FDM Model Material as Support

When it’s down to the wire, often reducing a parts build time is critical with 3D printing. Just in time manufacturing sometimes is just that, and shaving every minute out of a build can be the difference. In previous blogs we have explored the topics of reducing build time by changing raster and contour properties, in this blog we will be talking about using model material as support.

With all Stratasys FDM printers 2 dis-similar materials are fed through separate tips while printing. The first being model material which is used to produce the geometry of the final part. The second is a dedicated support material used to create a support like matrix under any surface that may sag or drupe if left unsupported. In most complex geometry builds both materials are used in each layer requiring the printer to change which print head is active.

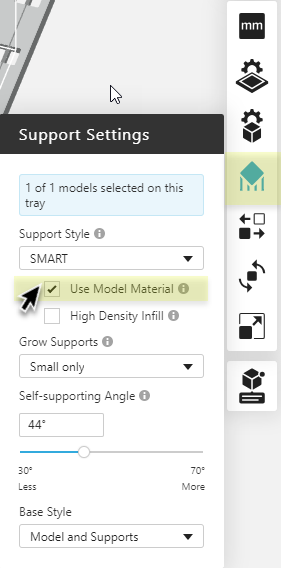

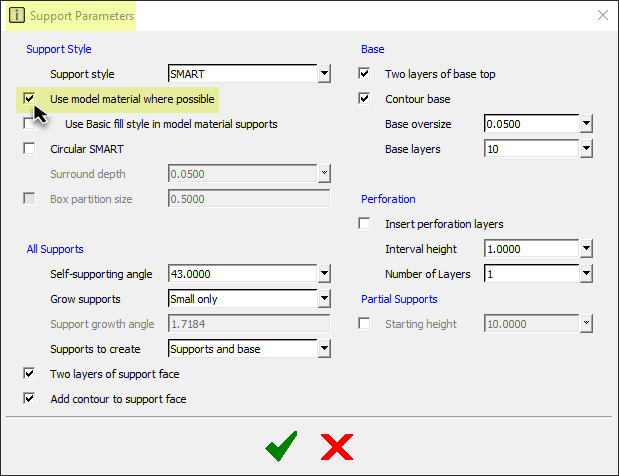

In GrabCad print or Insight by enabling the “use model as support” option the machine will print with model material as support wherever possible while leaving a few layers of the dedicated support material to interface with the part. This process allows for some layers to only use model material and skip the use of the dedicated support material all together. By using model material as support, it prevents the need for the temperature of one tip to cool down to an idle temperature while the other tip ramps up to printing temperature. While this may seem like a short process it can add up to a considerable sum of time on multi day builds.

GrabCAD Stratasys Insight

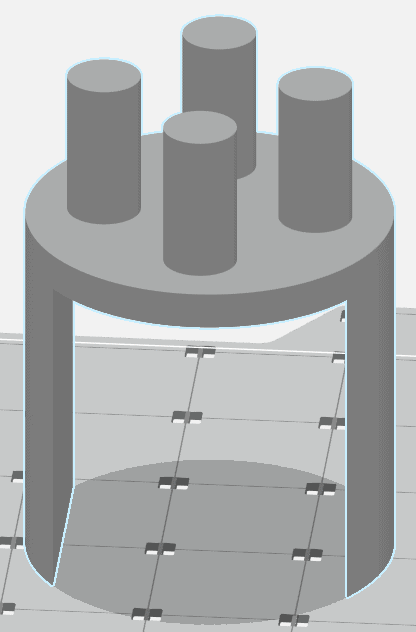

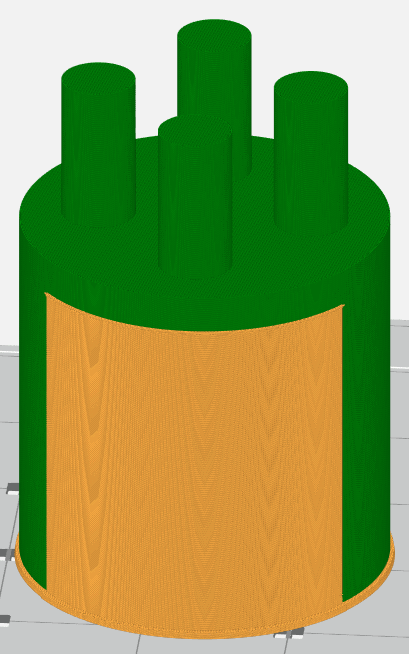

Now let’s talk about how to get the most out of this feature. Geometries that have supported features far away from the build tray tend to have the largest time savings. Long stretches of layers where no support interface is occurring will save a considerable amount of active material changes during the build. An added bonus of using model material as support is less soluble support material will be dissolved in the chemical bath, allowing for more parts to be cleaned per tank of detergent.

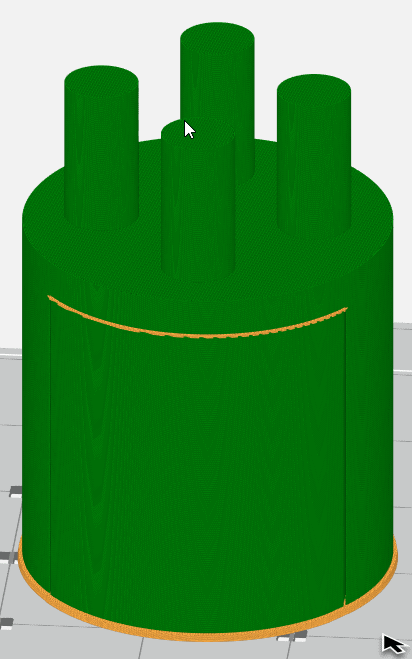

Model Basic Support Model as Support

It should be noted that not all geometries will benefit from this feature. If support interface with the part geometry is required on most layers, the machine will still need to change the active material in those layers. More than likely causing little to no time savings. Additionally, caution needs to be taken to ensure captive areas are not filled with model material as support. It can be easy to forget the convenience of soluble support material and replace hard to access regions with model material as support.

When used in combination with the other blog topic the time saving can start to have a large impact on your productivity. Sometimes it takes only a few minutes in the preparation to save hours on the build.

Ryan Henigan

Manufacturing Solutions Intern

Computer Aided Technology, Inc.

Blog

Blog