Importance of 3D Scanners in Reverse Engineering

In my role as Reverse Engineering Specialist with CATI, I have seen many methods used in reverse engineering. I have used quite a few of them also. In this blog, we are going to look at the various techniques to gain a better understanding of why 3D Scanners are so helpful in this area and how other techniques can be used.

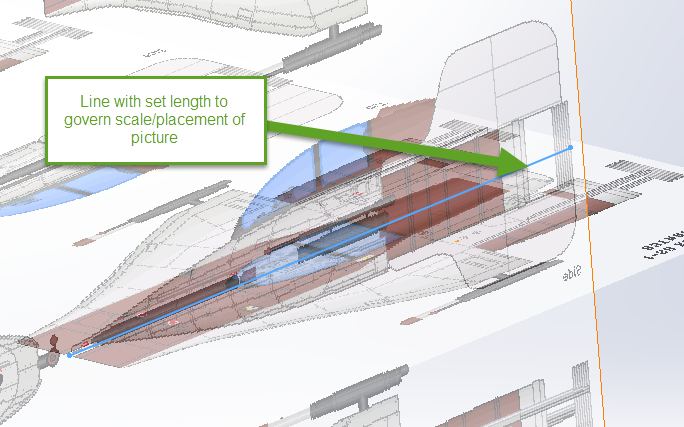

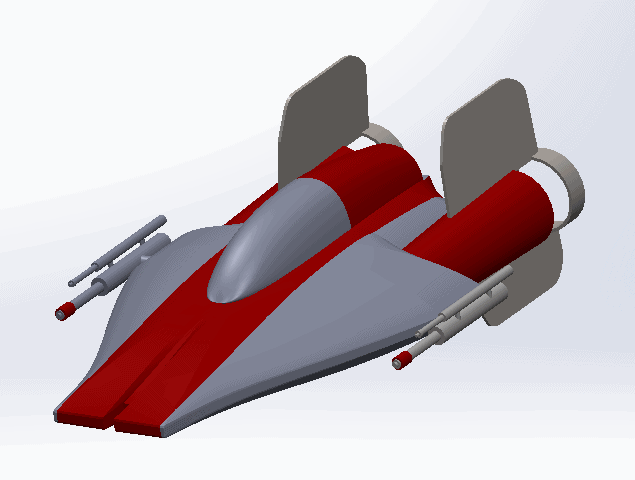

The first method I ever used is the “Sketch Picture” method. This is used when you don’t actually have a physical object to measure. Instead, you have pictures from different angles to guide the design. An example of this is shown below. I don’t have an actual model of the A-Wing from Star Wars, but I was able to find the schematic pictures of the ship and place them on different planes using a previously drawn sketch line to govern scale and placement of the picture.

Using these as guides, the final design came together very well! While this method does work, keep in mind that results would be different for each person doing this and that you are using eyeball guesstimates for everything.

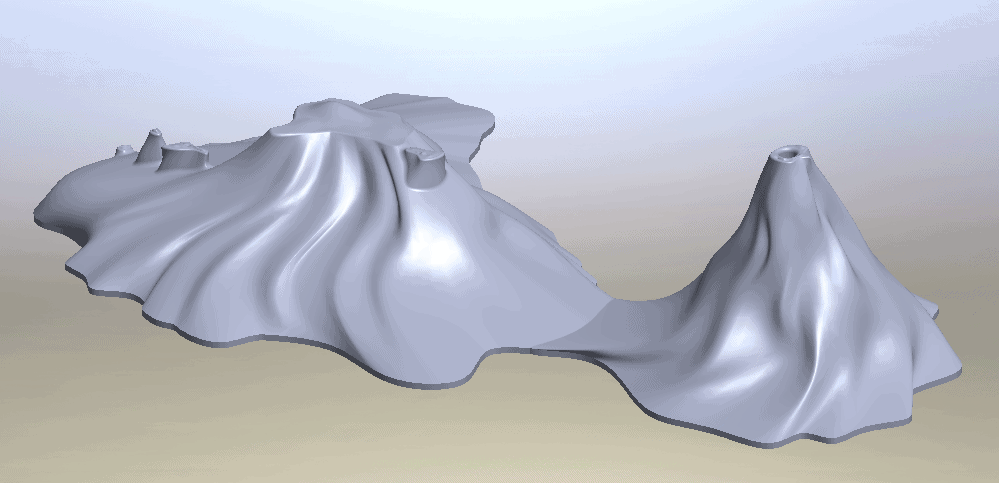

The next method is using measuring tools. I have heard of people using calipers, rulers, yardsticks, measuring tapes, etc. These should only be used when fine accuracy is not a concern. It is impossible to get the fine repeatable measurements every time using these methods. Even when using devices like digital calipers, the results can be skewed by how much each person pushes the slide portion onto the object. Experienced users can reliably get good and even great results, but hand those same tools to another user, even an experienced one and you will see some differences. Also, some surfaces cannot be measured using any of these tools. While the picture below (a model of one of the Aleutian Islands) might be an extreme example, it is an example of something that would be impossible to measure accurately with these types of tools.

Repeatability, reliability, accuracy; these are some of the most important reasons why 3D scanners are so valuable in reverse engineering. Creaform 3D scanners give high accuracy and the knowledge that no matter who is operating the scanner, the results will be the same. As we like to say in our demos, “They are so easy to use, even a sales guy can do it!” Creaform 3D scanners coupled with their internal module VXmodel or external program like Geomagic Design X, reverse engineering projects has become very fast and easy. We have seen customers go from taking 2-4 weeks to finish a reverse engineering project, down to 1-3 days!

For any and all other questions regarding Creaform 3D Scanners, contact Computer Aided Technology to get in contact with one of our local 3D scanning experts!

[raw]

[/raw]

Chad Whitbeck

CATI Reverse Engineering Specialist

Computer Aided Technology

Blog

Blog