Weldments and Bill of Materials

There are many different ways to create structural frames. One method might be creating it as an assembly with many individual parts. Another method, which is my preferred way, would be as a single multibody part…as a Weldment.

The Weldment way allows for easy design changes, automatic structural member trimming/extensions, and creation of cut lengths. This however is typically just a portion of the overall design. There might be many more pieces that go on the frame. This is when you would add your Weldment design to an assembly.

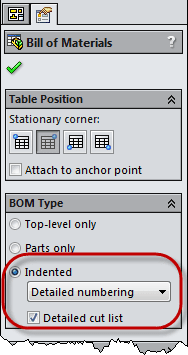

Now with your Weldment in the assembly and the other components attached, you need a Bill of Materials (BOM). It’s possibly to show the cut list for all the structural members in an assembly BOM. You will need to choose a BOM Type of Indented in the PropertyManager.

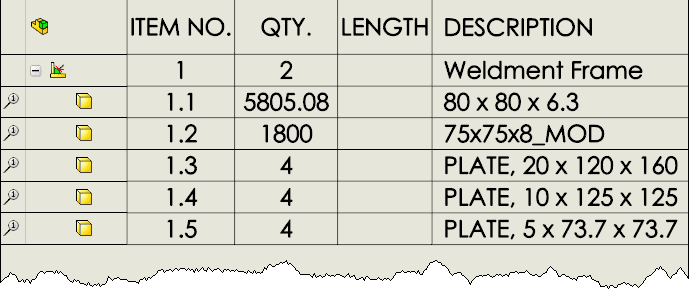

Once you choose the indented type, the BOM will show as a cut list. The QTY column shows a total length for the structural member.

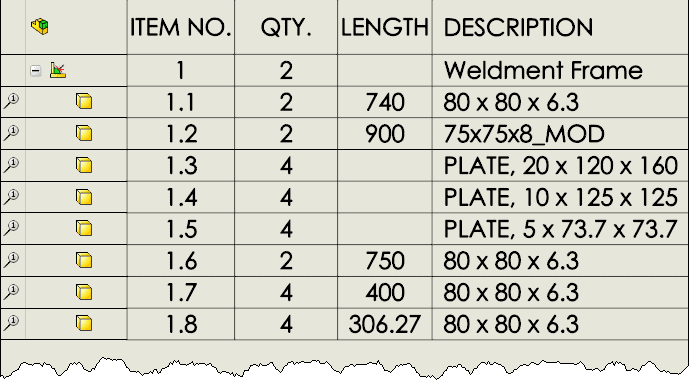

If you then choose “Detailed cut list” in the BOM Type, it will break each member out in their own row with a length value.

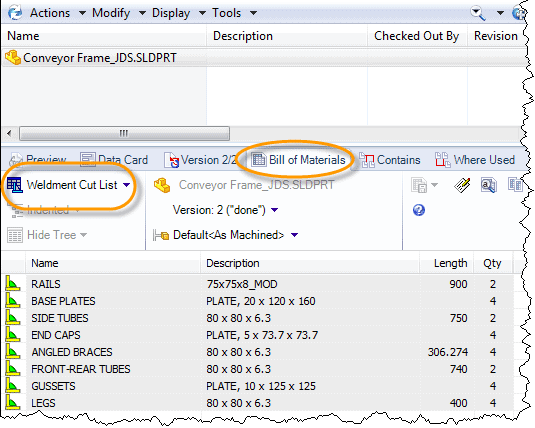

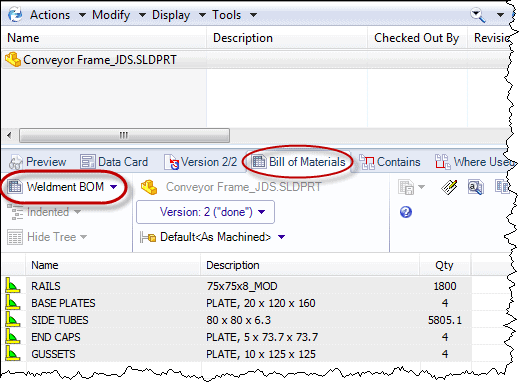

Now your assembly BOMs can show all the individual items even in the Weldment. But what if you are using Enterprise PDM. Can you see the cut list in EPDM? Of course you can. It is under the Bill of Materials tab. You would need to set-up a Weldment Cut List template in EPDM but that is very simple.

As you can see, the cut list item names can be shown to make finding the correct member easy. Just like in a drawing, you can choose to see a Weldment BOM.

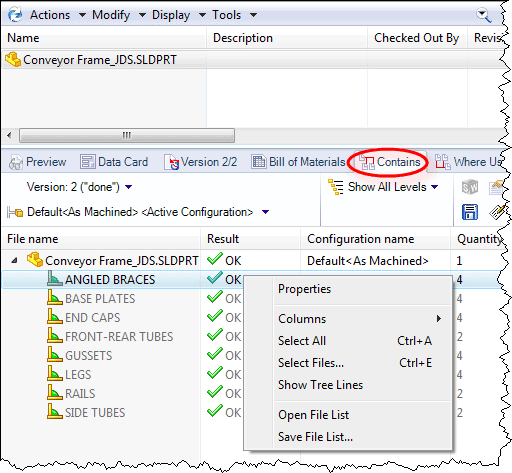

This will group all the members together giving you a total quantity. If you select the “Contains” tab, and RMB on a Weldment member, you get some more useful functionality.

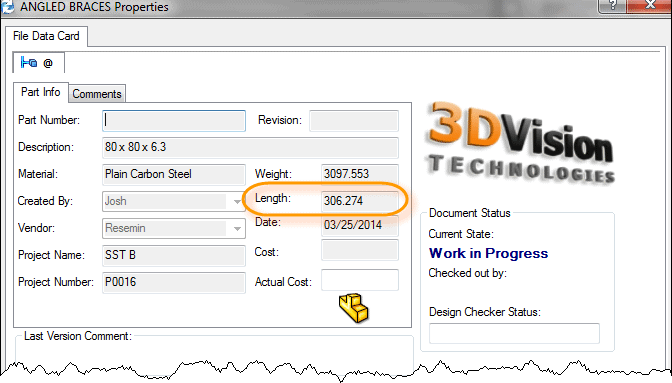

When you choose “Properties”, you can see the members data card with the length.

You will need to add the length field to the card and map it to the “BOM Quantity” variable.

Blog

Blog