SOLIDWORKS 3D CAD

Software and Product Design Tools

SOLIDWORKS Design Software

SOLIDWORKS 3D CAD has the most efficient and powerful CAD design collection available for product and part assembly designers. The SOLIDWORKS CAD suite of tools allows you to grow your business out of an intelligent, effortless SOLIDWORKS seed, so your organization can scale, flourish, and adapt to the 3D modeling changes for decades to come.

Leverage Your 3D CAD Work in SOLIDWORKS

- Analyze the manufacturability

- Validate assemblies with intuitive FEA and CFD tools

- Store your data in a secure location

- Build technical documentation for your customers and vendors

- 3D print your designs

- Showcase rendered data on your website or any eCommerce experience for your customer

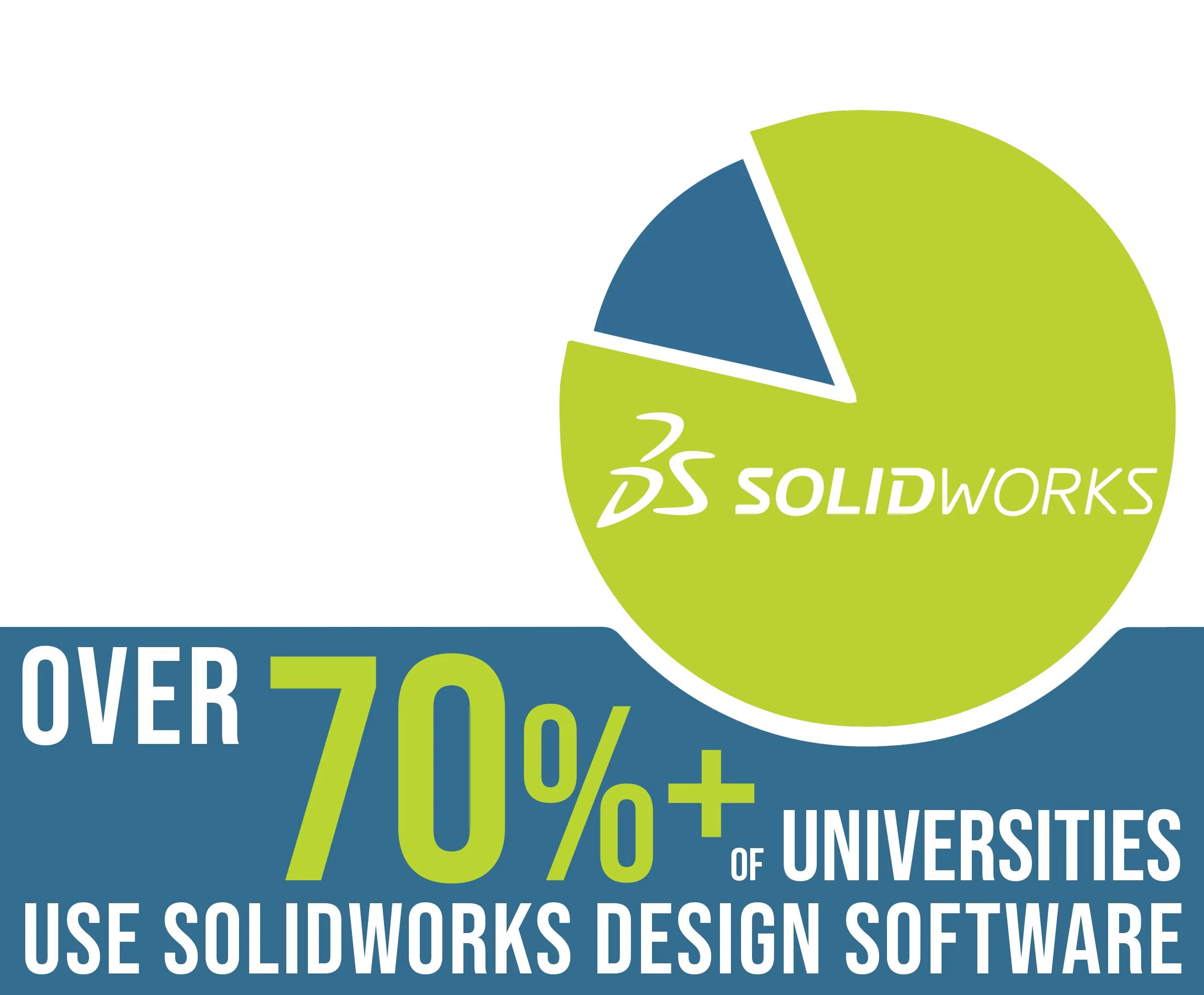

Is SOLIDWORKS the Right Choice?

SOLIDWORKS 3D CAD is overwhelmingly the primary choice for large and small organizations as well as 70% of engineering schools and universities for its easy-to-use interface and wealth of capabilities. No matter which avenue your design needs to be successful, SOLIDWORKS has the most efficient and powerful portfolio to get there.

SOLIDWORKS WHITEPAPER

Going Beyond Design: Making CAD the Cornerstone of an Integrated Design-to-Manufacturing Process

SOLIDWORKS drives better team and company performance by uniting design, engineering, testing, quality control, tooling, and other disciplines within a single unified ecosystem. Read this SOLIDWORKS whitepaper to learn more about how SOLIDWORKS Premium offers:

- Virtual product simulation

- Design validation

- CNC tool path generation

- Tooling development

- Costing and quoting capabilities

- Documentation development

SOLIDWORKS Packages

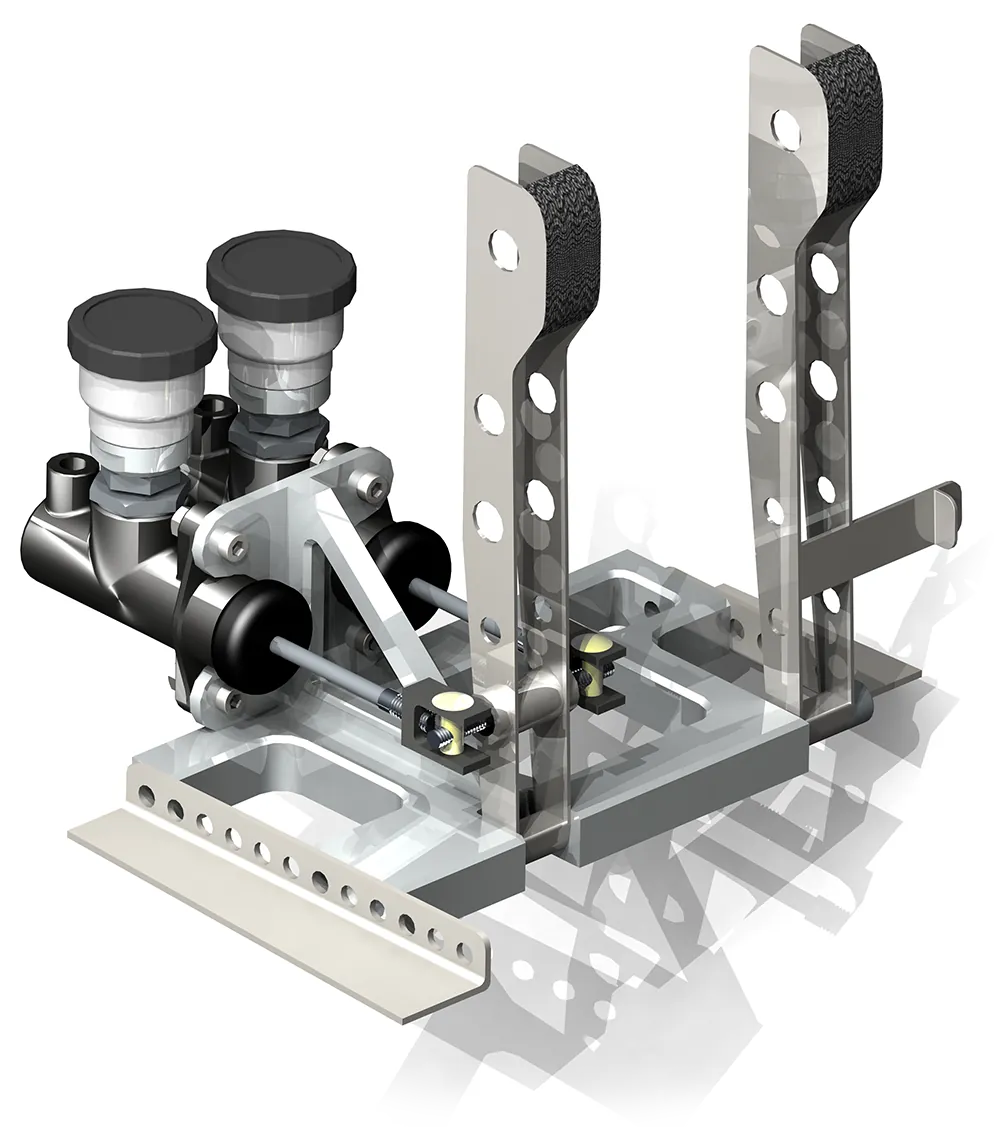

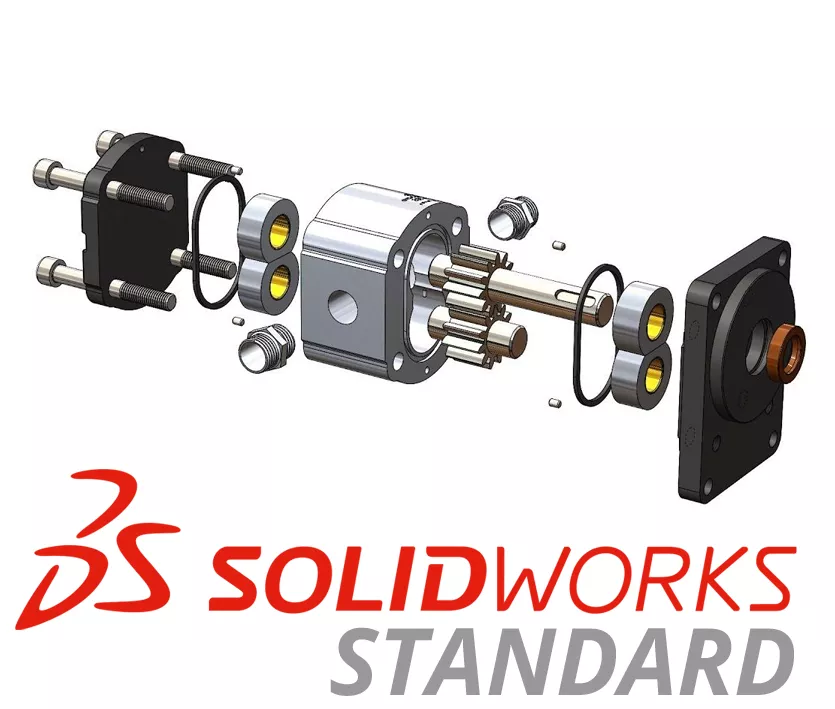

Get up to speed quickly with SOLIDWORKS Standard and unlock the benefits of this powerful 3D design solution for the rapid creation of parts, assemblies, and 2D drawings. Application-specific tools for sheet metal, weldments, surfacing, and mold tool and die, make it easy to deliver best-in-class designs.

SOLIDWORKS Professional builds on the capabilities of SOLIDWORKS Standard to increase design productivity, with file management tools, advanced photorealistic rendering, automated cost estimation, eDrawings® Professional collaboration capabilities, automated design and drawing checking, plus a components & parts library.

SOLIDWORKS Premium is a comprehensive 3D design solution that adds powerful simulation and design validation to the capabilities of SOLIDWORKS Professional, as well as ECAD/MCAD collaboration, reverse engineering, and advanced wire and pipe routing functionality for all types of industry product and part 3D modeling.

Compare SOLIDWORKS Packages

SOLIDWORKS 3D CAD

Cloud Services

*must be current on Support

Part and Assembly Modeling

2D Drawings

Design Reuse and Automation

Collaborate and Share CAD Data

Interference Check

First-Pass Analysis Tools

CAM Programming (SOLIDWORKS CAM Standard)

*must be current on Support

Design for Manufacturing (DFM)

Productivity Tools

Advanced CAD File Import/Export and Interconnect

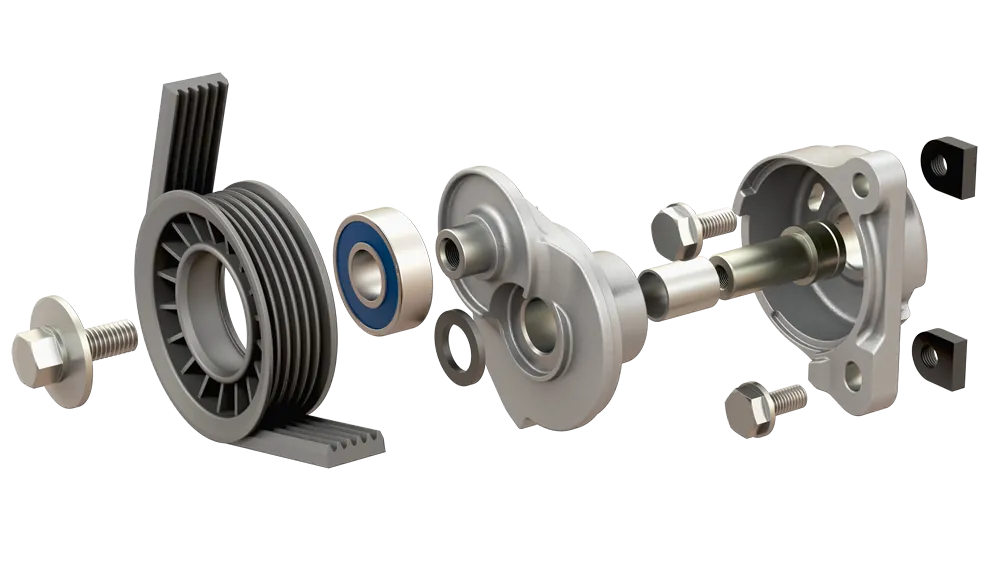

SOLIDWORKS Toolbox

Is a fully integrated and a customizable library of standard parts. Toolbox allows you to conveniently drag and drop common hardware components into your assembly. The hardware components support international standards, such as: ANSI, AS, GB, BSI, CISC, DIN, GB, ISO, IS, JIS, and KS.

Included Hardware:

- Bearings

- Bolts

- Cams

- Gears

- Jig bushings

- Nuts

- PEM® insert

- Pins

- Retaining rings

- Screws

- Sprockets

- Structural shapes, including aluminum and steel

- Timing belt pulleys

- Unistrut®

- Washers

SOLIDWORKS Costing

SOLIDWORKS costing is here to help calculate the manufacturing cost for sheet metal, fabricating weldments, creating machined parts, casting, plastic molded parts, 3D printing prototypes and assembly costs. Let SOLIDWORKS costing automate your estimation and quotation process.

Circuitworks

CircuitWorks allows users to create 3D models in SOLIDWORKS from common industry standard ECAD files like IDF, IDX and PADS ASCII. CircuitWorks has its own, dedicated user interface and a SOLIDWORKS user interface. Communication between UI is bi-directional making it easy to modify your circuit board layout, while visualizing your changes in SOLIDWORKS.

Design Checker

Produce the best version of your product with design checker. Use design checker as a validation step in your workflow for dimensioning standards, fonts, materials, and sketches to ensure the product meets your standards.

Edrawings Professional

Increase your team’s productivity by marking up the design, checking measurements or taking a quick cross section view in eDrawings Professional. Whether you need to share 3D and 2D cad models to the shop floor or send them to your manager to advance the project to the next stage, eDrawings is here to accelerate the design process. eDrawings Pro allows engineering teams to quick and conveniently collaborate about their designs.

Tolanalyst

TolAnalyst or Tolerance Analysis is used to review and verify tolerances between features in an assembly to ensure proper alignment when being assembled. TolAnalyst is used to report the effects of dimensional stack up, reducing risks for the end user assembling the product.

SOLIDWORKS Visualize

Reduce your time to market by creating photorealistic renderings of your models. Save money on costly cameras, lighting, backgrounds and creating prototypes with Visualize standard. Apply different colors and materials from a built-in library to enhance the way your product appears. Quickly produce high quality renderings through the design process and marketing phase to ensure you are producing the best version of your final product.

SOLIDWORKS FILE MANAGEMENT

Every company has a workflow whether it is well known or not. SOLIDWORKS PDM (Product Data Management) Standard integrates your workflow to manage the life cycle of your CAD data and any related documents. PDM also manages the history of your CAD file and keeps track of file references. You no longer need to worry about renaming or moving files. Rid yourself of maintaining version control and file management concerns with SOLIDWORKS PDM Standard.

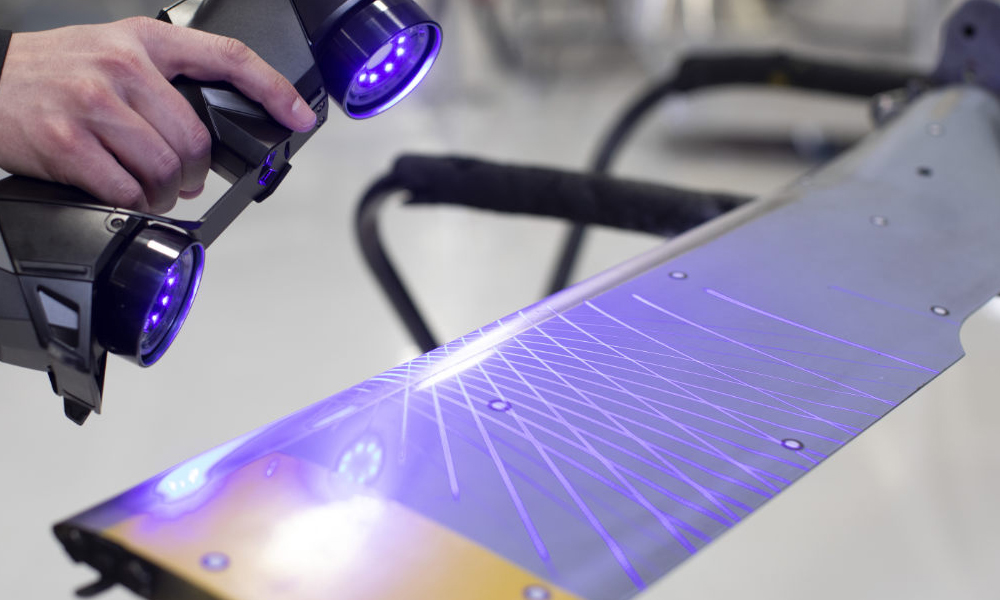

Scanto3D

ScanTo3D provides users a series of tools to import, prepare and convert scanned data into useable surface or solid geometry. Whether you are an engineer looking to recreate a discontinued part, or a consumer product designer creating a representation of a physical model, ScanTo3D is here to make the conversion process simple.

Time-Based Motion Analysis

Set up your motion study to capture a presentation worthy animation, that accounts for mass of parts, contact between components and gravity. Use motion analysis to simulate and evaluate the motion of components in your assembly by applying forces, friction, springs, and dampers. Motion analysis has a built-in kinematic solver that considers motion constraints, material properties, collisions, and mass. Understand how your assembly will move with motion studies.

Linear Static Analysis

SOLIDWORKS simulation is one of the most popular Finite element Analysis tools on the market. Making it easier to collaborate amongst SOLIDWORKS users to ensure your product is the best version of itself. Static analysis for parts & assemblies allows for easy stabilization of your model by applying fixed restraints. SOLIDWORKS simulation will save you on costly prototyping, analyzing field failures and ultimately protecting your product reputation.

PIPE and Tube Routing

SOLIDWORKS routing does the leg work for generating pipes and tube paths between components. Out of the box SOLIDWORKS has a time saving amount of predesigned fitting for your routing needs. As you create your pipe and tube route, SOLIDWORKS handles the organization of your feature manager making it easy for design change.

SOLIDWORKS WIRING

SOLIDWORKS routing saves time and material by accurately placing electric cables and wiring harnesses for your electrical route. You can Import from-to lists to quickly generate your electrical route which can easily be sent to a drawing to display the flattened electrical harness. Take advantage of the library of electrical connectors to quickly route your electrical cables and wiring harnesses.

Advanced Surface Flattening

Whether you are trying to make decals for your product, or if you need a template to accurately cut material, SOLIDWORKS surface flatten is here to help. SOLIDWORKS advanced surface flatten is great for generating flat patterns of faces and surfaces of your model.

Rectangular and other section routing

Take advantage of the existing ducting and cable tray components in the design library. These intelligent components are easily customizable using built in design tables. Laying out your ducting has never been easier. Simply drag and drop components from the design library to modify and update your route.

Catia v5 import

SOLIDWORKS CATIA V5 Import uses 3D Interconnect expertise, allowing designers to effortlessly incorporate CATIA files directly into their SOLIDWORKS models.

+

Simulation Pro/Premium

What Kind of System do I need for SOLIDWORKS?

Visit our SOLIDWORKS System Requirements page to see the official system requirements and get 10% off preconfigured SOLIDWORKS workstations from Dell.

Still Confused About SOLIDWORKS OPTIONS?

Check out GoEngineer's SOLIDWORKS Buying Guide and get answers to these common questions:

and much more!

SOLIDWORKS Services:

Utilize GoEngineer’s Award Winning Support & Training for SOLIDWORKS

Award Winning Technical Support

GoEngineer's extensive SOLIDWORKS technical knowledge and world class support can help you succeed with SOLIDWORKS. Our award-winning team is ready to help you with any task you may have. Using state-of-art remote assistant technology software allows our team to solve most issues within one session. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

- 125+Certified Technical Specialists

- Email, Phone and Chat Support Available

- 98% Exceptional Customer Service Rating

PROFESSIONAL SOLIDWORKS TRAINING

GoEngineer offers online and classroom professional SOLIDWORKS training for organizations and individuals. All our instructors are SOLIDWORKS certified and teach thousands of students each year world wide. The curriculum is very diverse with numerous certified SOLIDWORKS courses to choose from. Each student will receive a Course Completion Certificate and preparation materials for SOLIDWORKS certification.

- Increase Your Earning Potential

- Led by Certified SOLIDWORKS Instructors

- Smaller Classes with Focused Attention

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet, SL, or Metal 3D printers. 3D Printing Services