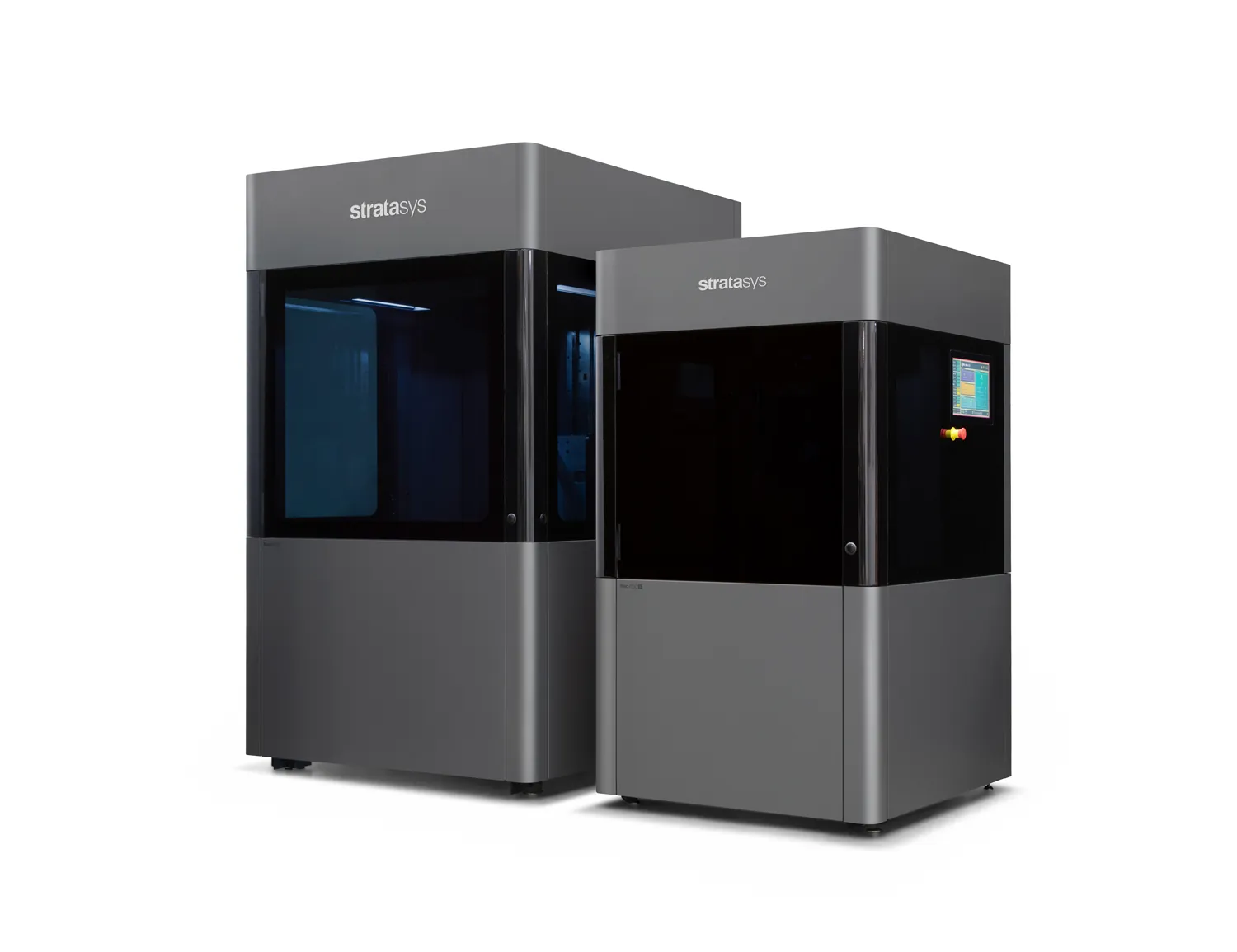

STRATASYS NEO

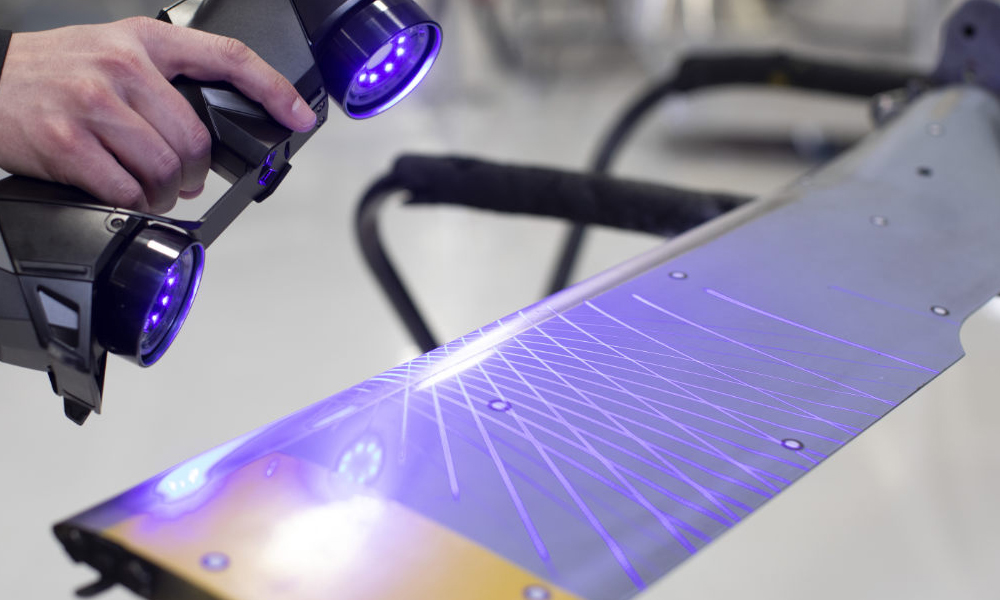

Open-system Stereolithography 3D Printers

Streamline your workflow

The open-system Stratasys Neo 3D Printer uses Stereolithography (SL) technology to deliver dependable, scalable fabrication at unprecedented speeds. Harness the power and performance you need to create precise parts efficiently and affordably.

NEO optimizes your STEREOLITHOGRAPHY NEEDS

Versatile

Versatile

Choose your resin, build styles, laser power, and beam size adjustments. Open-source material capability offers the option to use any 355nm SL resin. This flexibility allows you to tailor the Neo to your specific stereolithography needs.

Precise

Precise

Features as small as .006” (X & Y) or 0.016” (Z) are achievable thanks to the adjustable beam size (80-750um) and Z layer height (50-200um).

Efficient

Efficient

Neo stereolithography 3D printers are equipped with a powerful laser, 3-axis dynamic scanning system, and advanced software algorithms to allow fast printing of parts over the entire build area.

Features

Innovative. Intuitive. Productive.

The user-friendly Neo family of 3D printers utilizes the industry "gold-standard" Materialise Magics software for SL build preparation. The printers run efficiently with minimum user intervention via the proprietary "Titanium" machine control software, thus allowing teams to utilize printing time to the fullest.

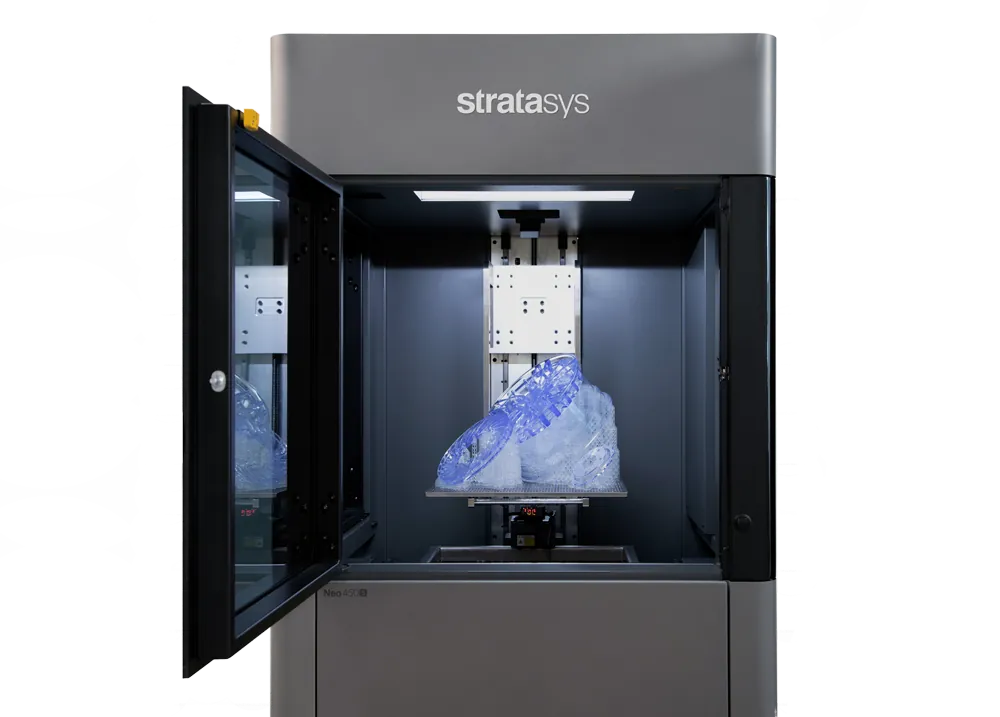

HIGH QUALITY PARTS

Neo Stereolithography printers can create large parts with outstanding surface finish and high resolution. Part quality is consistent at large volumes and highly repeatable.

A Complete STEREOLITHOGRAPHY WORKFLOW

The Neo line includes a UV curing oven and unloading cart for a seamless post processing workflow. After printing, residual resin can be removed using cleaning solvents applied manually or via a semi-automated solution. Once clean, parts cure for an average of 6 minutes per side under UV lamps.

MATERIALS

SOMOS 9120

Semi-Flexible/moveable parts

- Strong memory retention

- Semi-flexible

- Superior chemical resistance

- Translucent appearance

- Easy to use and finish

Potential applications:

– Automotive parts

– Electrical casings

– Fluid flow analysis

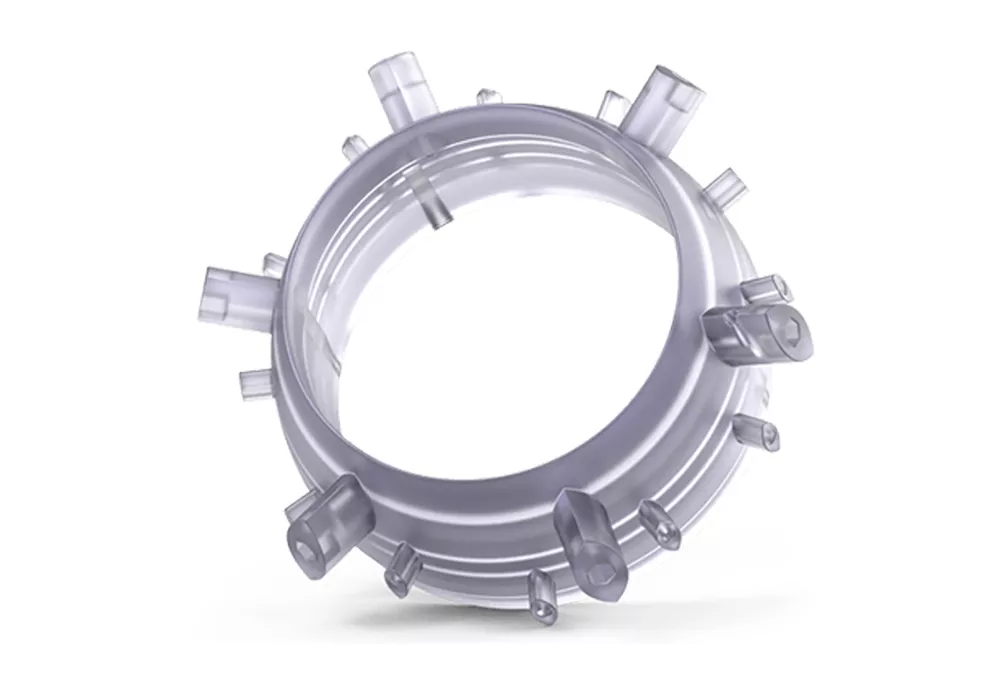

Somos BioClear

Clear & Accurate Medical Models

– Passed stringent ISO 10993-5 Cytotoxicity, ISO 10993-10 Irritation & Sensitization and USP Class VI testing

- High accuracy and surface quality

- High moisture resistance

- Complex shapes and feature detail

- Eliminates chemical texturing process

- Exceptional clarity facilitates inspection of feature detail and quality

- Resistant to common solvents

Potential applications:

- Anatomical models for surgical planning

- Surgical guides

- Non-implantable/limited contact medical applications

- Functional prototypes with body contact

Somos DMX-SL 100

Hollow Composite Tooling

- Extreme durability

- Greater design freedom

- High feature detail and smooth finish

- Faster part design

Potential applications:

- Automotive & transportation: ducts, pipes and conduits, high-end automotive intake pipes, fluid-holding tanks, electric vehicle (EV) battery cooling solutions

- Consumer products: sports and leisure goods, luxury goods, interior design

- Electronics: bespoke light-weight enclosures, complex wiring looms, robotic components

- Healthcare: precision-molded internals for prosthetics

Somos Element

Formulated for investment casting

- Antimony-free

- Very clean burnout with low residual ash

- Low viscosity

- Dimensionally stable

Potential applications:

- Investment casting patterns

Somos EvoLVe 128

Durability with Easy Finishing

- Easy to clean & finish

- High strength & durability

- Accurate & dimensionally stable

- High detail

Potential applications:

- Aerospace, automotive, medical, electronic applications

- Consumer products

- Tough, functional prototypes

- Snap-fit designs

- Jigs & fixtures

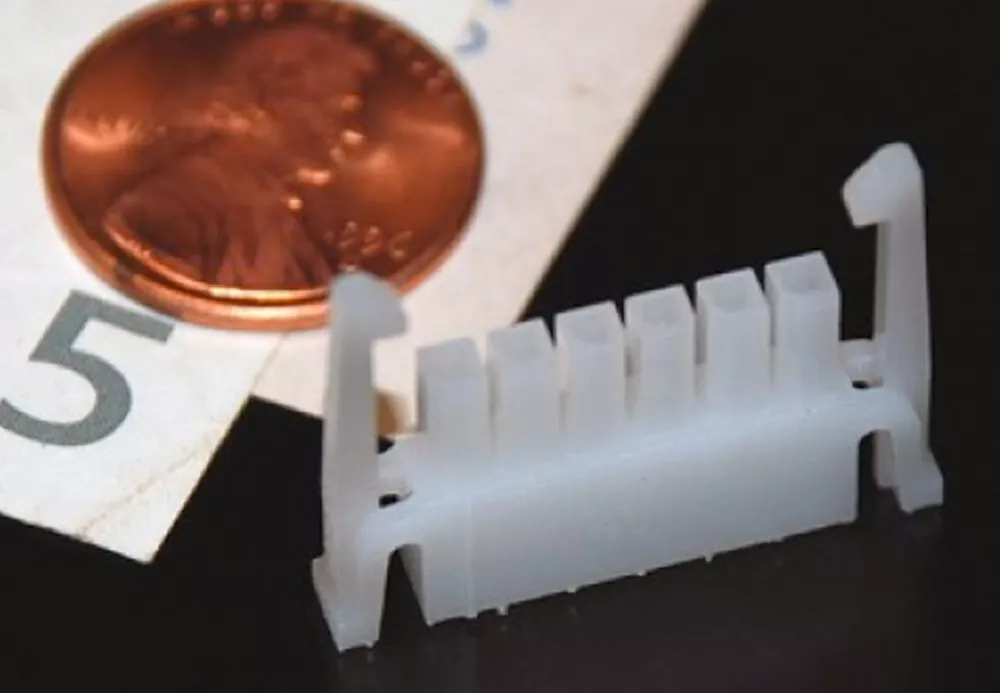

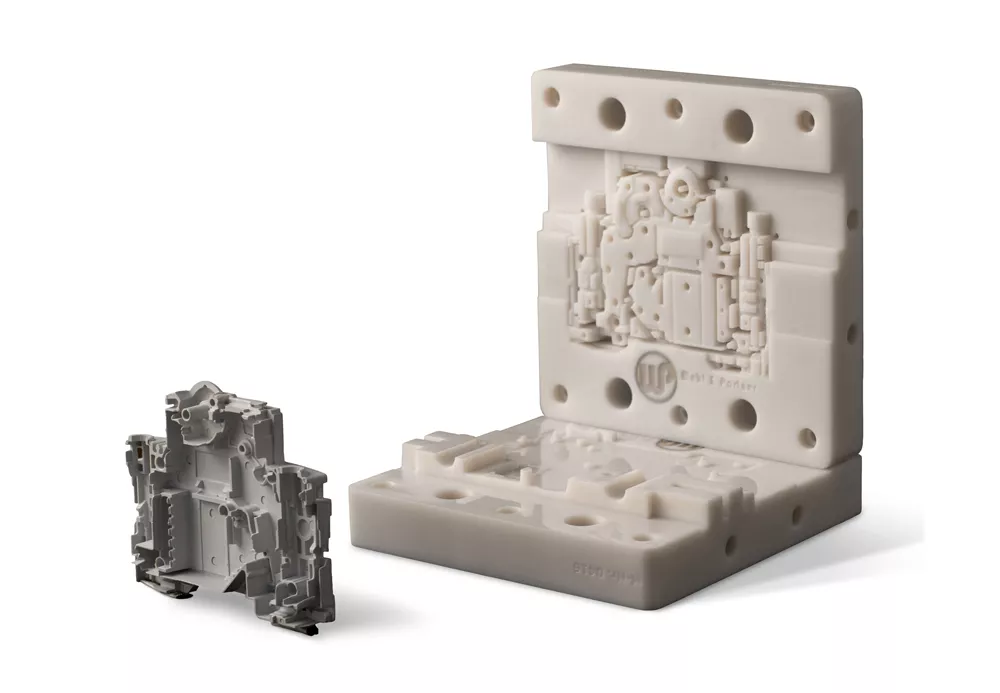

Somos GP Plus 14122

For functional prototyping

- ABS- and PBT-like material

- Extremely accurate

- Excellent humidity resistance

- Very durable

- Opaque white appearance

Potential applications:

- Functional prototypes

- Concept models

- Aerospace parts

- Consumer product parts

- Low volume production parts

Somos NeXT

Look and Feel of Thermoplastics

- Superior strength and durability

- Exceptionally versatile

- Thermoplastic-like performance, look and feel

Potential applications:

- Aerospace, automotive, medical consumer products, electronic applications

- Tough, functional end-use prototypes

- Snap-fit designs

- Impellers

- Duct work

- Connectors

- Electronic covers

- Automotive housings

- Dashboard assemblies

- Jigs and fixtures

- Packaging and sporting goods

Somos PerFORM

Strong & Temperature REsistant

- Excellent detail resolution

- Faster, easier processing & finishing

- Superior high heat tolerance

- Expanded applications

Potential applications:

- Tooling

- Wind tunnel testing

- High temperature testing

- Electrical casings

- Automotive housings

Somos PerFORM Reflect

PIV Wind Tunnel Testing

- Ready-to-use material for PIV wind tunnel testing

- Faster image processing, higher accuracy wind tunnel models

- >30% reduction in post-processing time

- Excellent detail resolution

- Improved surface quality, faster part finishing

- Superior high heat properties

Potential applications:

- PIV wind tunnel testing for aerodynamic design optimization

- High-temperature testing

- Electrical casings

- Automotive housings

- Tooling

Somos ProtoGen 18420

For accurate parts. Easy processing.

- Tune the properties of the part to fit your application needs

- Fast, easy processing & finishing

- Highly accurate

Potential applications:

- Electronic Covers

- Consumer Products

- Snap fit assembly

Somos ProtoTherm

Resistant to heat up to 250°F/121°C

- Extremely precise accuracy for small details

- Resistant to heat up to 250°F/121°C

- Stable in high humidity environments

Potential applications:

- Automotive

- Aerospace

- High-temperature fluid flow analysis

- Functional prototypes requiring heat and humidity resistance

- High-detail parts

- Low volume connectors and harnesses for electronics

Somos Taurus

High Heat Deflection

- Superior strength and durability

- Wide range of applications

- Excellent surface and large part accuracy

- Heat tolerance up to 90°C

- Thermoplastic-like performance, look and feel

Potential applications:

- Customized end-use parts

- Tough, functional prototypes

- Under the hood automotive parts

- Functional testing for aerospace

- Low volume connectors for electronics

Somos Watershed AF

investment casting patterns

- No detectable levels of antimony per ICP-AES test methodology

- Trace amounts of ash that are easily removed

- Low viscosity

- Dimensionally stable

- Suitable for high-end alloy castings

- Rapid draining

- Produces accurate, repeatable parts regardless of size

Potential applications:

- Investment casting patterns

- Aerospace and aviation applications

- Transportation applications

- Energy and utilities applications

- Jigs and fixtures/operational aids

- General purpose prototyping

Somos Watershed BLACK

eliminatES need for painting or coating

- Up to 50% faster processing speed than alternative black resins

- Truer black color off the machine

- Ease-of-use and fast processing with minimal finishing, more consistent processing over time

- Based on proven technology of Somos ® WaterShed XC 111222

- Smooth surface finish

- Superior moisture and chemical resistance

Potential applications:

- Durable, stiff, tough parts

- Automotive components

- Packaging

- Functional prototypes and end use parts

Somos Watershed XC 11122

CLEAR ABS properties

- Easy to print and to finish

- Superior moisture resistance

- Exceptional clarity

Material Options:

- Consumer products

- Fluid/Air Flow Analysis

- Duct work

- Investment casting

- Lenses

Somos WaterClear Ultra

optically clear stereolithography

- Extraordinary optical clarity

- Superior moisture resistance

- Easy to use and finish

- Colorless

Material Options:

- Automotive lenses

- Bottles

- Lenses

- Light pipes

- Fluid flow analysis

- Master patterns

- Concept and functional models

Specifications

System Size and Weight

41.3 × 48.2 × 74.8", Printer: 1323 lb, Vat: 221 lb

Laser & Scanning System

- Laser: 1 Watt, 355 nm, solid-state frequency tripled Nd: YV04

- Beam Focus: Dynamic

- Beam Size: 250 μm

- Scanning Speed: Up to 400 "/s

Layer Resolution

50 to 200 μm*

Minimum Feature Size

0.012 " X & Y / 0.016 " Z

Build MOdes

SD

Build Speed

In like-for-like comparisons, build times are up to 40% shorter than the Neo™450s 1w laser model.

Accuracy

Dimension <3.94 " ±0.004 ". Dimension >3.94 " ±0.1%

Material Compatibility

Open resin system - compatible with 355 nm stereolithography resins

Capacity

| Short: | Half: | Full: | |

| Build (XYZ) | 17.72 × 17.72 × 1.97 " | 17.72 × 17.72 × 7.87 " | 17.72 × 17.72 × 15.75 " |

| Vat Fill | 10 US gal (95 lb) | 22 US gal (203 lb) | 37 US gal (348 lb) |

Software

- Operating System: Windows 10 Pro

- Input File Format: SLC

- Control Software: Titanium™

- Remote Editor: Titanium Assistant™ (Optional)

Connectivity

- Ethernet: Fully compliant with IEE 802.3, IEEE 802.3u, IEEE 802.3ab

- WIFI: Fully compliant with IEEE 802.11 b/g/n (optional)

- USB Port: USB 3.1

Features & Build Options

Build validation / Build time estimator / Material usage estimator / Open build parameters enabling any material to be processed / On-the-fly parameter adjustment & part deletion / Upper surface build quality optimisation / Bubble remover with automated option / Scheduled start

Electrical Requirements

- 110 ~ 120 Volt, 60 Hz - 300 W Typical operation, 550 W Max

- 220 ~ 240 Volt, 50 Hz - 700 W Typical operation, 1300 W Max

System Size and Weight

53.1 x 64.1 x 90.5", Printer: 1763 lbs, Vat: 529 lbs

Laser & Scanning System

- Laser: 2 Watt, 355 nm, solid-state frequency tripled Nd: YV04

- Beam Size: Dynamic focusing: 150 to 600 μm

- Scanning Speed: Up to 10 m/s

Layer Resolution

50 to 200 μm

Minimum Feature Size

0.006" X & Y / 0.016" Z

Build MOdes

HD & SD

SCANNING Speed

Up to 10 m/s

Accuracy

±0.15%

Accuracy will vary depending on parameters, part geometry and size, pre-processing or post-processing methods, materials and environment

Material Compatibility

Open resin system - compatible with 355 nm stereolithography resins

Capacity

| Short: | Half: | Full: | |

| Build (XYZ) | 31.49 x 31.49 x 4.72" | 31.49 x 31.49 x 11.81" | 31.49 x 31.49 x 23.62" |

| Vat Fill | 45 US gal (428 lb) | 79 US gal (740 lb) | 146 US gal (1388 lb) |

SOFTWARE

- Operating System: Windows 10 Pro

- Input File Format: SLC

- Control Software: Titanium™

- Remote Editor: Titanium Assistant™ (Optional)

CONNECTIVITY

- Ethernet: Fully compliant with IEE 802.3, IEEE 802.3u, IEEE 802.3ab

- WIFI: Fully compliant with IEEE 802.11 b/g/n (optional)

- USB Port: USB 3.1

Features & Build Options

Build validation / Build time estimator / Material usage estimator / Open build parameters enabling any material to be processed / On-the-fly parameter adjustment & part deletion / Upper surface build quality optimisation / Bubble remover with automated option / Scheduled start

Electrical Requirements

220 ~ 240 Volt, 50 Hz - 700 W Typical operation, 1300 W Max

System Size and Weight

53.2 × 64.2 × 90.6", Printer: 1764 lb, Vat: 529 lb

Laser & Scanning System

- Laser: 2 Watt, 355 nm, solid-state frequency tripled Nd: YV0 4

- Beam Focus: Dynamic & Variable

- Beam Size: 150 to 600 μm

- Scanning Speed: Up to 400 in./s (10 m/s)

Layer Resolution

50 to 200 μm*

Minimum Feature Size

0.008 in. (0.2 mm) in X & Y † / 0.016 in. (0.4mm) in Z †

Build Modes

HD & SD

Accuracy

Dimension <3.94 in. ±0.004 in.; Dimension >3.94 in. ±0.15%

†

Dimension <100 mm ±0.1 mm; Dimension >100 mm ±0.15%

†

Material Compatibility

Open resin system - compatible with commercially available

355 nm stereolithography resins

Capacity

| Build (XYZ) | 31.50 × 31.50 × 23.62 in. (800 × 800 × 600 mm) |

| Vat Fill | 147 US gal (1389 lb‡) [555 ltr (630 kg‡)] |

Software

- Operating System: Windows 10 Pro

- Input File Format: SLC

- Control Software: Titanium™

- Remote Editor: Titanium Assistant™ (Optional)

Connectivity

- Ethernet: Fully compliant with IEE 802.3, IEEE 802.3u, IEEE 802.3ab

- USB Port: USB 2.0

Features & Build Options

Build validation / Build time estimator / Material usage estimator / Scheduled start / Open build parameters enabling any material to be processed / On-the-fly parameter adjustment & part deletion / Upper surface build quality optimization / Bubble remover with automated option.

Electrical Requirements

208 ~ 240 V, 50/60 Hz, 900 W Typical operation, 1900 W Max

Software

Materialise Magics

The Most Powerful 3D Printing Data Preparation Software

Materialise Magics makes prepping a 3D design file for printing easy, intelligent, and fast. Magics is a smart, versatile data preparation and STL editing software for 3D printing and additive manufacturing. The powerful industry-leading software walks the operator through every step of the 3D printing workflow.

ADDITIONAL 3D Printing RESOURCES

AWARD-WINNING TECHNICAL SUPPORT

GoEngineer’s extensive technical knowledge can assist with your additive manufacturing needs. Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

3D Printing Courses

Learn to utilize all features and tools of Stratasys commercial 3D printers with GoEngineer additive manufacturing on-boarding training and 3D printing courses. Take advantage of our 3D printing team of experts to help launch all your 3D printing capabilities.

3D PrintING SERVICES

No matter the size, quantity, or complexity of part(s) needed, GoEngineer can help you! Take advantage of our 3D Printing Services to help your organization produce the best parts and prototypes available on the market.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet, SL, or Metal 3D printers. 3D Printing Services