STRATASYS F770

A Large Format Industrial Scale 3D Printer

Now Serving US & Canada

Now Serving US & Canada

ACCESSIBLE LARGE FORMAT FDM 3D PRINTING

The Stratasys F770 allows you to print on larger scale, without breaking your budget. A reliable and simple way to print large, complex parts.

Features

STRAIGHTFORWARD OPERATION

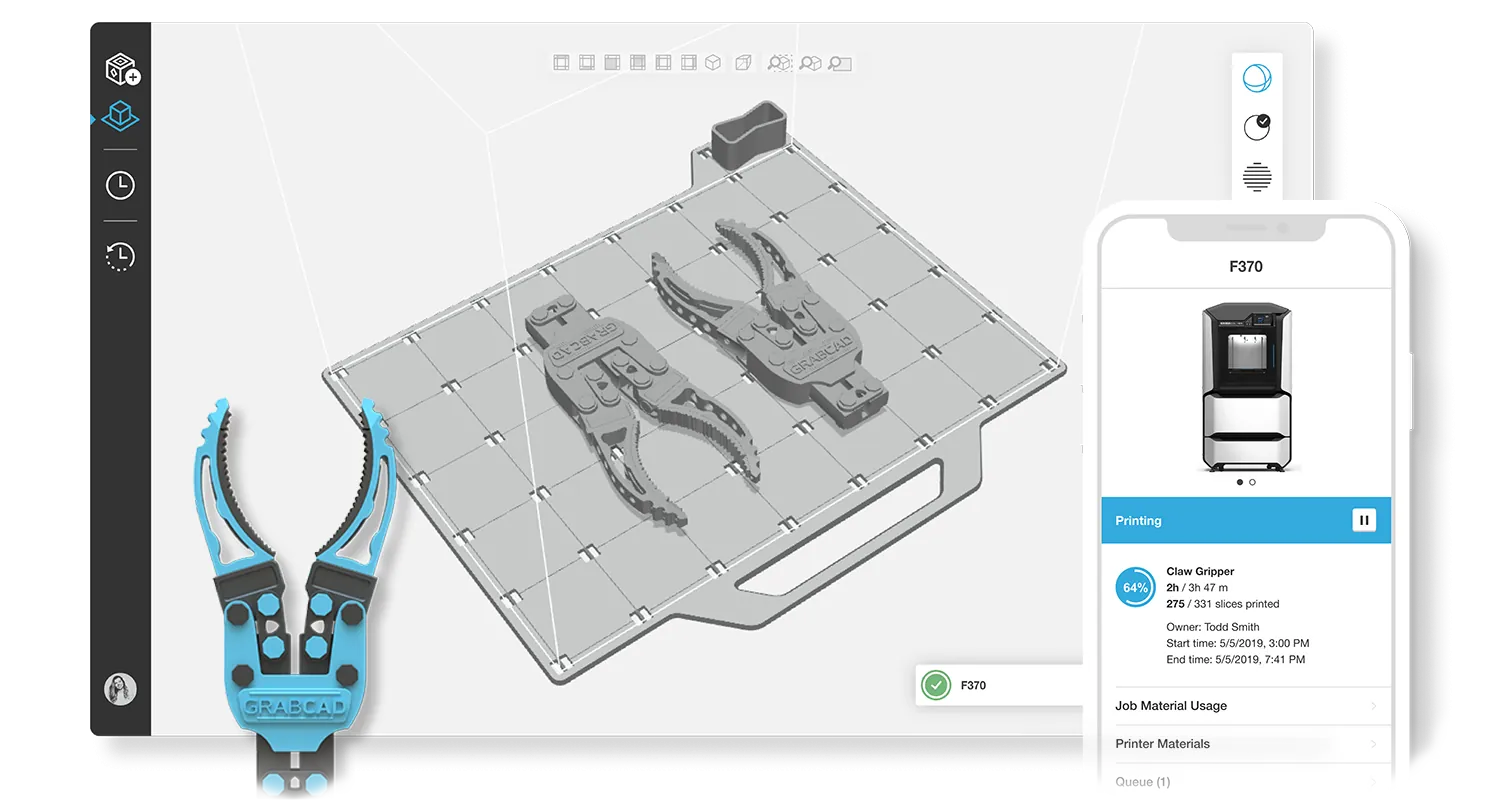

Printing with the Stratasys F770 requires no special training. It is engineered with plug-and-print simplicity that allows any team member to print large parts with ease. No need to constantly monitor the F770 either, material canisters enable up to 140 hours of unattended printing. Prints can be monitored 24/7 with the F770's built in camera, and viewed on your mobile device via the GrabCAD print app.

Industrial Scale meets affordable

Large format 3D printing doesn't have to be a large investment. The Stratasys F770 achieves affordability by focusing on widely used engineering-grade materials, instead of niche high performance alternatives, and building off of the extremely reliable Stratasys FDM platform.

Print large, or Print many

With the longest heated chamber on the market, you can print over 48 inches long on a diagonal, or take advantage of the space to make multiple parts simultaneously. Achieve quantity as well as quality, thanks to soluble support structures that ensure you'll never have to compromise on the complexity of your parts.

F770 MATERIALS

ASA

Acrylonitrile styrene acrylate

– New Standard material for all-purpose prototyping

– UV-stabilized for outdoor production parts

– Superior aesthetics and 10 color options

– All-around average mechanical performance

Potential applications:

– Conceptual models

– Functional prototypes

– Manufacturing tools

– Production parts

ABS-M30

Acrylonitrile Butadiene styrene

– High performing ABS blend 25-70% stronger than standard

– Versatile, well-understood material

Potential applications:

– Conceptual models

– Functional prototypes

– Manufacturing tools

– Production parts

SR-30

DISSOLVABLE SUPPORT

– SR-30 works seamlessly with ABS, ASA. Thanks to focused development SR-30 can yield impressive ABS and ASA prints not possible with PVA.

Potential applications:

– Conceptual models

– Functional prototypes

– Manufacturing tools

– Production parts

F770 Specifications

System Size and Weight

- 175 x 124 x 196 cm (69 x 49 x 77 in.)

- 658 kg (1450 lbs.)

BUILD ENVELOPE

- 1000 x 610 x 610 mm / 372,000 cm 3 (39.4 x 24 x 24 in. / 22,677 in 3 )

-

Maximum length on the diagonal – 1,320mm (51.9 in.)

MATERIALS

- ASA – Ivory

- ABS-M30™ – Black

- SR-30™ soluble support material

MATERIAL DELIVERY

- 200 in 3 coil box (3277 cm 3 )

ACHIEVABLE ACCURACY

- XY part accuracy = +/- 0.254 mm (+/- 0.010 in.) or +/- 0.002 mm/mm (+/- 0.002 in./in.), whichever is greater

- Z part accuracy = +/- 0.200 mm (+/- 0.008 in.) or +/- 0.002 mm/mm (+/- 0.002 in./in.), plus 1 layer height

SOFTWARE

- GrabCAD Print, Insight, Control Center™, MTConnect enabled

-

U.S. government agency STIG compliance via Stratasys ProtectAM technology is powered by Red Hat® Enterprise Linux® software.

WORKSTATION COMPATIBILITY

- Wired and wireless (with USB dongle) network interfaces using standard TCP/IP protocols at 100 MBPS minimum

OPERATING CONDITIONS

- Operating temperature 15 °C to 30 °C (59 °F to 86 °F)

- Operating Humidity 30-70% - 39 in. clearance on each side of printer

POWER REQUIREMENTS

- 3 phase, 208V, 30A, 5 wire, 47-63 Hz frequency

Audible Noise/AcousticS

- 54 dBA

Regulatory Compliance

- 3 phase, 208V, 30A, 5 wire, 47-63 Hz frequency

Wireless Network Connectivity

- IEEE 802.11n-2009

- IEEE 802.11g-2003

- IEEE 802.11b-1999

Software

GrabCAD Print

make 3D printing easy, with thoughtful features:

- Automatically corrects files and reduces print time with automatic tray arrangement.

- Calculates the time and material resources needed for production before printing.

- 3MF file supported – significantly simplifies color assignment in your workflow.

- New feature alerts the user if there has been cross-contamination with a biocompatible material.

- Schedule and monitor the print job remotely from your mobile device or browser.

- Get automatic alerts remotely when the job is printing and finished.

ADDITIONAL 3D Printing RESOURCES

AWARD-WINNING TECHNICAL SUPPORT

GoEngineer’s extensive technical knowledge can assist with your additive manufacturing needs. Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

3D Printing Courses

Learn to utilize all features and tools of Stratasys commercial 3D printers with GoEngineer additive manufacturing on-boarding training and 3D printing courses. Take advantage of our 3D printing team of experts to help launch all your 3D printing capabilities.

3D PrintING SERVICES

No matter the size, quantity, or complexity of part(s) needed, GoEngineer can help you! Take advantage of our 3D Printing Services to help your organization produce the best parts and prototypes available on the market.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services