Stratasys F900

The ultimate 3D production system

Now Serving US & Canada

Now Serving US & Canada

RETHINK EVERYTHING

The Stratasys F900 3D Printer is the most precise and powerful FDM system available. With the largest build size of any Fortus system, the Stratasys F900 is designed to handle the most demanding manufacturing needs.

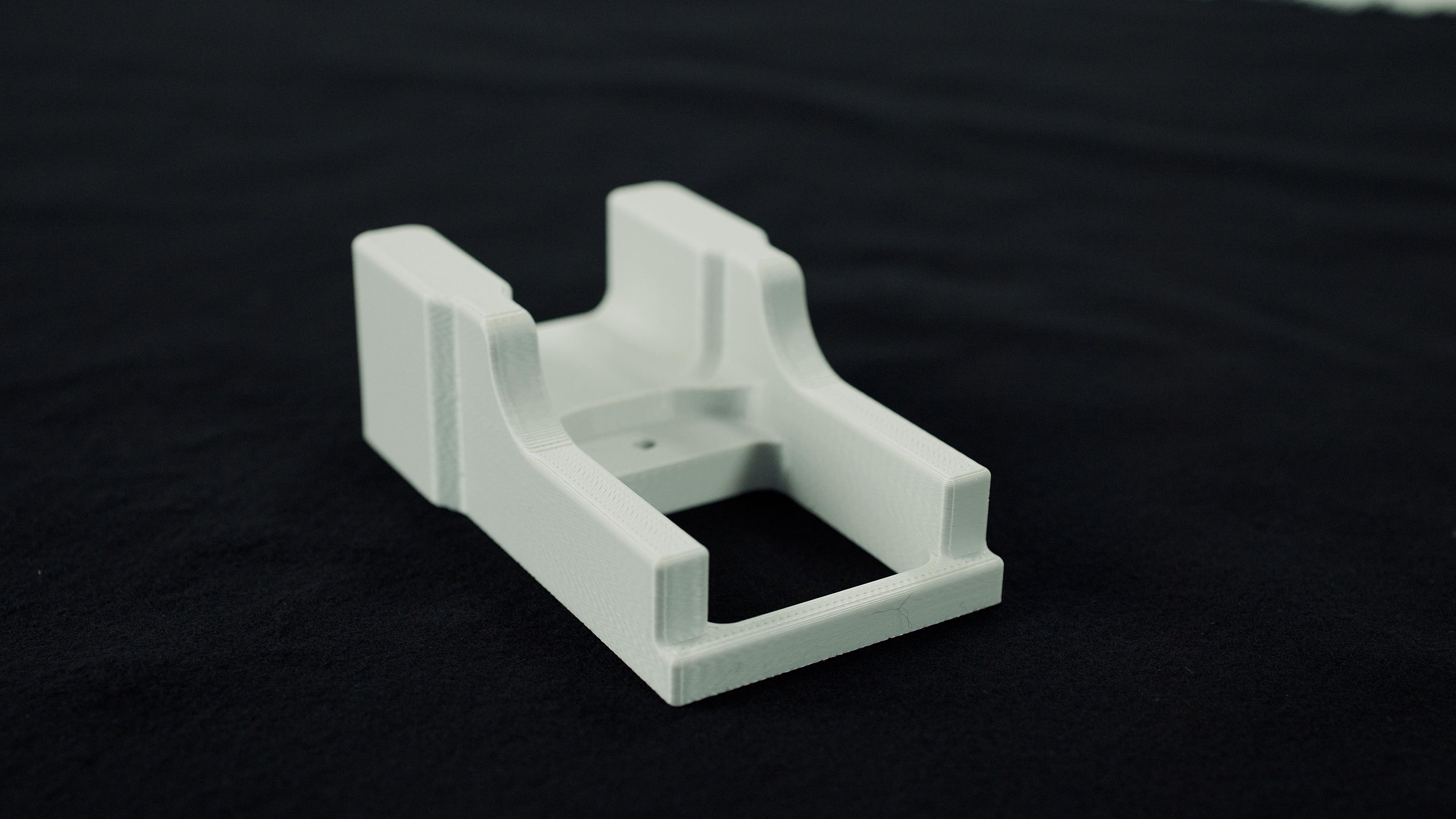

The Stratasys F900 uses engineering-grade thermoplastics to build robust production parts, jigs, fixtures, factory tooling, and functional prototypes. Large parts are printed fast with the standard, large T40A tip to help meet production demands with ease.

The Stratasys F900 offers a streamlined workflow and easier job monitoring with an internal camera, GrabCAD Print software, and MTConnect readiness.

Most VERSATILE, RELIABLE, ACCURATE and PROVEN 3D MANUFACTURING SYSTEM:

- 16 industrial-grade materials

- Wide range of print resolutions (0.005″ up to 0.020″)

- Stratasys’ largest FDM print area (commercially available)

DATA-DRIVEN - Connectivity and Visibility

- Live data analytics – MTConnect-ready

- Accessible, informative, and easy-to-read job reports

RISK REDUCING FEATURES

- Tamper-resistant files (Confidential Flag) – locked CMB files

- Moisture management and monitoring – dew point monitor and powerful airflow dryer

- Production monitoring – internal camera

F900 MATERIALS

* Material needs specialized upgrades to 3D Printer to operate

ASA

Acrylonitrile styrene acrylate

– New Standard material for all-purpose prototyping

– UV-stabilized for outdoor production parts

– Superior aesthetics and 10 color options

– All-around average mechanical performance

Potential applications:

– Conceptual models

– Functional prototypes

– Manufacturing tools

– Production parts

ABS-M30

Acrylonitrile Butadiene styrene

– High performing ABS blend 25-70% stronger than standard

– Versatile, well-understood material

– Available in a biocompatible version

• ABS-M30i | ISO 10993 USP Class VI (can only print in Fortus machines)

Potential applications:

– Conceptual models

– Functional prototypes

– Manufacturing tools

– Production parts

ABS-M30i

High Strength, Sterilizable FDM Material

– Biocompatible

– High-strength

– Sterilizable

Potential applications:

– Medical uses

– Food handling

– Pharmaceutical handling

– Surgical planning models and tools

ABS-ESD7

Acrylonitrile Butadiene styrene

– Static-dissipative material based on ABS-M30

– Prevents build-up of static electricity

– Electrical Properties:

• Volume Resistivity: 3.0×109 – 4.0×1010 ohm-cm

• Surface resistance: 106 – 109 ohms

Potential applications:

– End-use components

– Electronic products

– Industrial equipment

– Jigs & fixtures

PC-ABS

Polycarbonate + Acrylonitrile Butadiene styrene

– Blended material that shares properties with ABS and PC

– Highest impact strength of Stratasys FDM materials

– Good toughness, durability, and heat resistance

– Available on the F123 platform

Potential applications:

– Conceptual models

– Functional prototypes

– Manufacturing tools

– Production parts

PC

Polycarbonate

– Material known for its superior strength and durability

– Stable material that will not change shape over time

– Available in a biocompatible version

• PC-ISO | ISO 10993 USP Class VI | F900 only

– Great material for use on the shop floor

Potential applications:

– Demanding prototypes

– Tooling & fixtures

– Metal bending patterns

– Composite patterns

– Medical production parts

Nylon 12

Polyamide

– Composite material

– Moderate chemical resistance

Potential applications:

– High-fatigue endurance

– Repetitive snap fits

– Friction-fit inserts

Nylon 6

Polyamide

– New standard material for all-purpose prototyping

– Fills the niche between Nylon 12 and Nylon 12CF

– Excellent combination of strength and toughness

– Good choice for production floor environment

Potential applications:

– Production tooling

– End-use parts

– Tough prototypes

ST-130

Soluble Model Material

– Engineered and tested specifically for sacrificial tooling applications

– High compressive strength

– Triangle fill pattern to optimize process speed | Build & dissolution

– Capable of Autoclave cure

Potential applications:

– Temporary pattern for hollow composite parts

PPSF/PPSU

Polyphenylsulfone

– Built for demanding applications

– Excellent chemical resistance

– Good heat resistance and mechanical strength

– Suitable choice for “under the hood” scenarios

– Sterilizable

– Steam | ETO | Plasma | Chemical | Radiation

Potential applications:

– Concept models

– Functional prototypes

– Production parts

– Manufacturing tools

ULTEM 1010

Polyetherimide

– Excellent strength & thermal stability

– Highest heat resistance of any FDM material 421˚F

– Flame, smoke, and toxicity rating

• 14 CFR/FAR 25.853 | ASTM F814/E662

– Available in general purpose or biocompatible grade

• ULTEM 1010CG | NSF51| ISO10993 Class VI

Potential applications:

– Advanced functional prototypes

– Production parts

– Manufacturing tools and patterns

ULTEM 9085

Polyetherimide

– Flame-retardant, high performing material

– High thermal & chemical resistance

– Flame, Smoke, and Toxicity rating

• 14 CFR/FAR 25.853 | ASTM F814/E662

– Fungus resistant

• MIL-STD-810G

– Available in general purpose or certified grade

• Raw & filament analysis | lot number traceability

Potential applications:

– Advanced functional prototypes

– Production parts

– Manufacturing tools and patterns

Nylon 12CF

Polyamide + Chopped Carbon Fiber

– Composite material with 35% chopped carbon fiber reinforcement

– Highest flexural strength and stiffness-to-weight ratio FDM material

– Moderate chemical resistance

– Static dissipative qualities

Potential applications:

– Metal component replacement

– Production parts

– Tooling

Antero 800NA

Polyetherketoneketone

– Pekk-based super material

– Strong mechanical properties

– Excellent chemical resistance

– Minimal outgassing and dimensional stability

Potential applications:

– Everything aerospace

– Production parts

– Advanced functional prototypes

Antero 840CN03

Polyetherketoneketone + Carbon Nanotubes

– Pekk-based super material

– Electrostatic dissipative

– Ultra-low outgassing

– Electrical properties:

• Volume Resistance: 104 – 109 ohm

– Outgassing properties:

• Total Mass Loss (TML): 0.41-0.45 %

• Water Vapor Recovered (WVR): 0.15 – 0.17 %

• Collected Volatile Condensable Materials (CVCM): <0.01 – 0.01%

Potential applications:

– Production parts

– Advanced functional prototypes

VICTREX AM 200

PEEK

– PEEK-Based copolymer

– Wear resistant

– Heat resistant

– Chemical resistant

– Soluble support compatible

Potential applications:

– End-use parts

– Jigs & fixtures

– Functional prototyping

– Manufacturing aids

FDM Hips

High-impact polystyrene

– High impact resistance

– General use

– Low cost

Potential applications:

– Jigs and Fixtures

– Manufacturing Aids

– Functional Prototypes

Kimya PC-FR

Polycarbonate (PC) - Flame Retardant

– Flame-resistent material

– Electrical insulator

– Good dimensional stability

Potential applications:

– Passenger and commerical rail

– Electrical

– Replacement of obsolete parts

F900 Specifications

Model Materials

- ABS-ESD7

- ABS-M30

- ABS-M30i

- ASA

- Nylon 12

- PC

- PC-ABS

- PC-ISO

- PPSF

- ULTEM 1010

- ULTEM 9085

- FDM Nylon 12

- FDM Nylon 6

- ST-130

- FDM Nylon 12CF

Support Structure

- Soluble for most materials

- Break-away for PC-ISO, ULTEM, and PPSF

- Soluble or break-away for PC

Material Delivery

Two bays each for model and support canisters

Network Connectivity

10/100 base T connection; Ethernet protocol)

Net build size

36 x 24 x 36 in.

Layer thickness

- 0.005 in.

- 0.007 in.

- 0.013 in.

- 0.010 in.

- 0.020 in.

Power Requirements

- 230VAC nominal three-phase service with 5% regulation

- 230VAC as measured phase-to-phase; 50 Hz or 60Hz; 40 Amp circuit

Achievable Accuracy

Parts are produced within an accuracy of ± .0035 in. or ± .0015 in/in, whichever is greater. (Accuracy is geometry dependent. Achievable accuracy specification derived from statistical data at 95% dimensional yield.)

Regulatory Compliance

CE, NRTL Listed

System Size and weight

2772 x 1683 x 2027 mm (109.1 x 66.3 x 78.1 in); 2869 kg (6325 lbs.).

With Manufacturing Light Tower: 2772 x 1683 x 2281 mm (109.1 x 66.3 x 89.8 in.)

Powerful Dryer

Moisture in materials leads to poor surface quality and failed builds. A powerful internal dryer reduces the risk of moisture in materials. 5X more airflow that the Fortus 900mc Gen 2 system. Airflow in the filament tube is increased to maintain dryness of the filament while loaded in the system.

Dew Point Monitor

- Immediately provides touchscreen warnings if dew point exceeds set levels

- Verifies the dew point within the filament tube

- Provides dew point reading via MTConnect

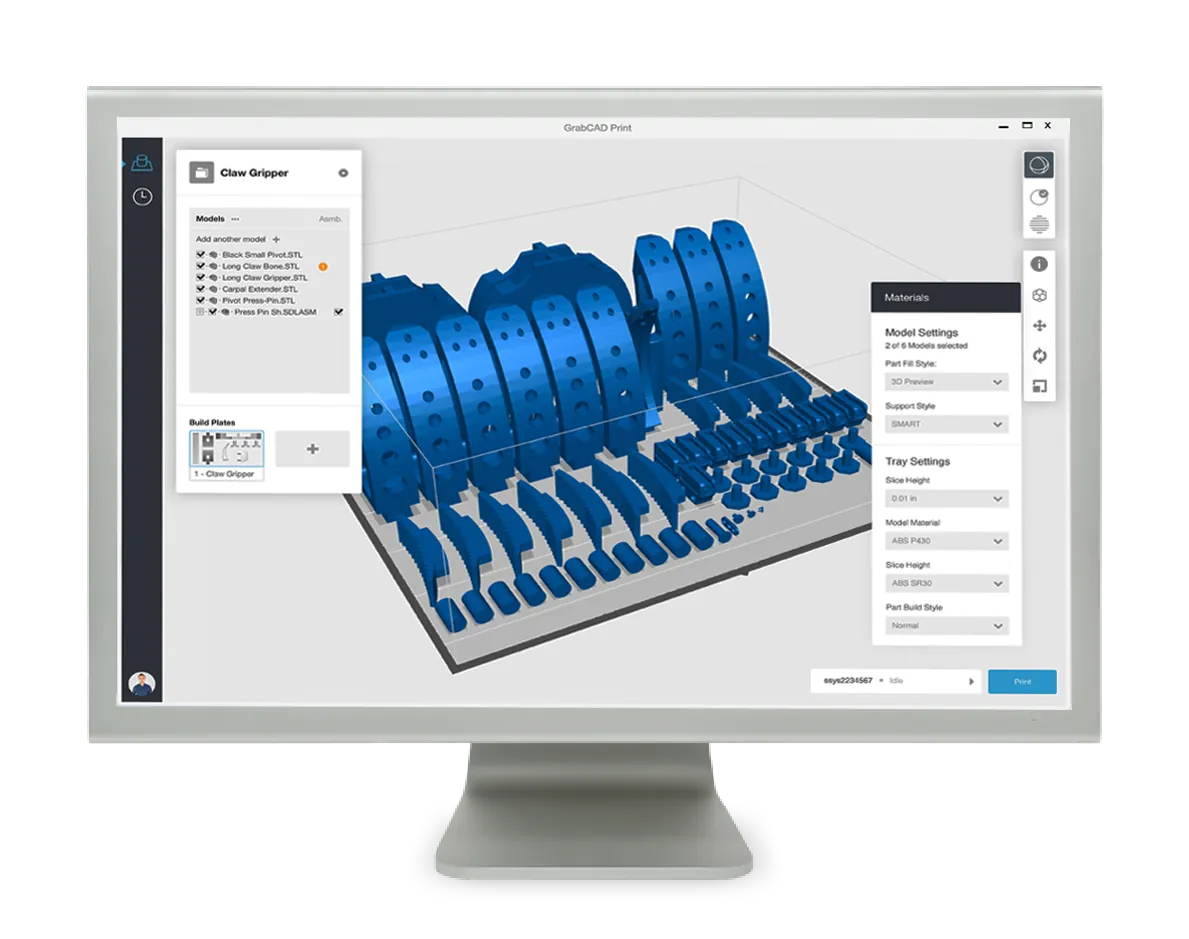

Software

GrabCAD Print

Professional 3D Printing Made Easy and Accessible

GrabCAD Print is the most complete solution for Stratasys 3D printers on the planet. The intuitive, easy-to-use software allows for simplified preparation, scheduling, monitoring, and reporting of print jobs. With the ability to read and understand CAD files natively, GrabCAD Print offers an efficient workflow that streamlines job management in shared office and model shop environments.

INSIGHT SOFTWARE

OPTIMIZE BUILD OUTPUT FOR 3D PRINTING

Insight software prepares your CAD program’s STL output for 3D manufacturing on a Fortus machine by automatically slicing and generating support structures and material extrusion paths. For maximum control, users can manually edit parameters that determine the look, strength, and precision of parts as well as the speed and material use of the FDM process.

- Optimize build orientation for maximum strength and smoothest surface finish

- Customize supports for fast, easy removal and best use of materials

- Program pauses into the build for any reason, such as to embed hardware or circuitry

- Manipulate tool paths for advanced control over part properties

Included with Insight is Control Center. This sophisticated software application communicates with user workstations and Fortus systems, to manage jobs and monitor production status. Design, engineering, and manufacturing teams can network and share 3D manufacturing capacity to maximize efficiency and throughput.

*Compatible with GrabCAD Print for use with job reports, scheduling, and remote monitoring.

Frequently Asked Questions

ADDITIONAL 3D Printing RESOURCES

AWARD-WINNING TECHNICAL SUPPORT

GoEngineer’s extensive technical knowledge can assist with your additive manufacturing needs. Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

3D Printing Courses

Learn to utilize all features and tools of Stratasys commercial 3D printers with GoEngineer additive manufacturing on-boarding training and 3D printing courses. Take advantage of our 3D printing team of experts to help launch all your 3D printing capabilities.

3D PrintING SERVICES

No matter the size, quantity, or complexity of part(s) needed, GoEngineer can help you! Take advantage of our 3D Printing Services to help your organization produce the best parts and prototypes available on the market.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services