STRATASYS J35 PRO 3D PRINTER

Desktop PolyJet Prototyping

Now Serving US & Canada

Now Serving US & Canada

Versatile In-house 3D Printing

The compact, affordable Stratasys J35 Pro brings engineering-grade, multi-material 3D printing to places it's never been before. The J35 Pro can produce prototypes, parts and models to meet the needs of a wide range of industries, including automotive, aerospace, consumer electronics, medical devices and more.

“Before we had the J35 Pro, we would spend lots of time communicating, preparing models. The entire process took weeks and lots of testing — and it did not always work. With our current in-house possibilities, we get most printing jobs done overnight and get many working models to share with our customers.”

– Yaniv Adir, Taga

top 5 Features

1. Multi-Material Printing

Print with three materials separately or simultaneously to create concept models, jig, fixtures, or functional prototypes.

2. Affordable Realism

Design realistic parts and prototypes with an all-in-one, multimaterial 3D printer. The J35 Pro is a low cost investment compared to comparable PolyJet multi-material printers.

3. Office-Friendly

The J35 Pro is an engineering grade printer, with a small footprint and silent and odor-free operation.

4. Simple Workflow

Leverage a diverse selection of workflow tools to streamline design powered by GrabCAD print, including cloud-based service, print to click (Keyshot), on demand training, and more.

5. Always Reliable

The J35 Pro is a highly reliable printer that needs little maintenance.

Improve the design process

Reduce time spent on manual models, iterate designs fast and save money by bringing 3D printing in-house. Designers and Engineers can produce polished and thoroughly tested prototypes without sacrificing speed.

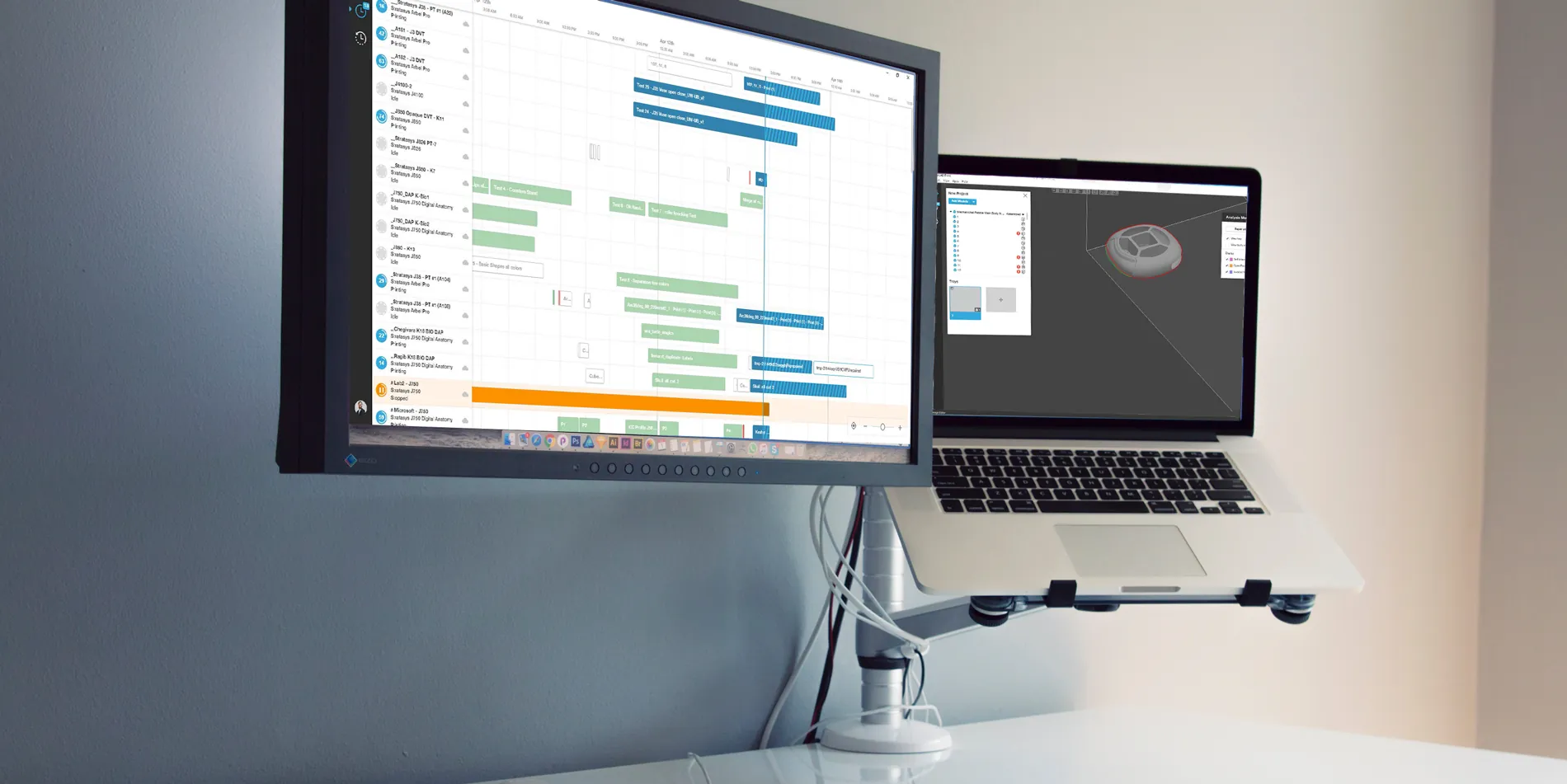

Intelligent Workflow

The J35 utilizes GrabCAD Print to present users with a simpilified workflow. Benefits include:

- Automatic File Fixing

- All CAD Formats Accepted

- Print Management and Delayed Prints

- Regular Monthly Updates

- Vast Multi-Material Print Capabilities

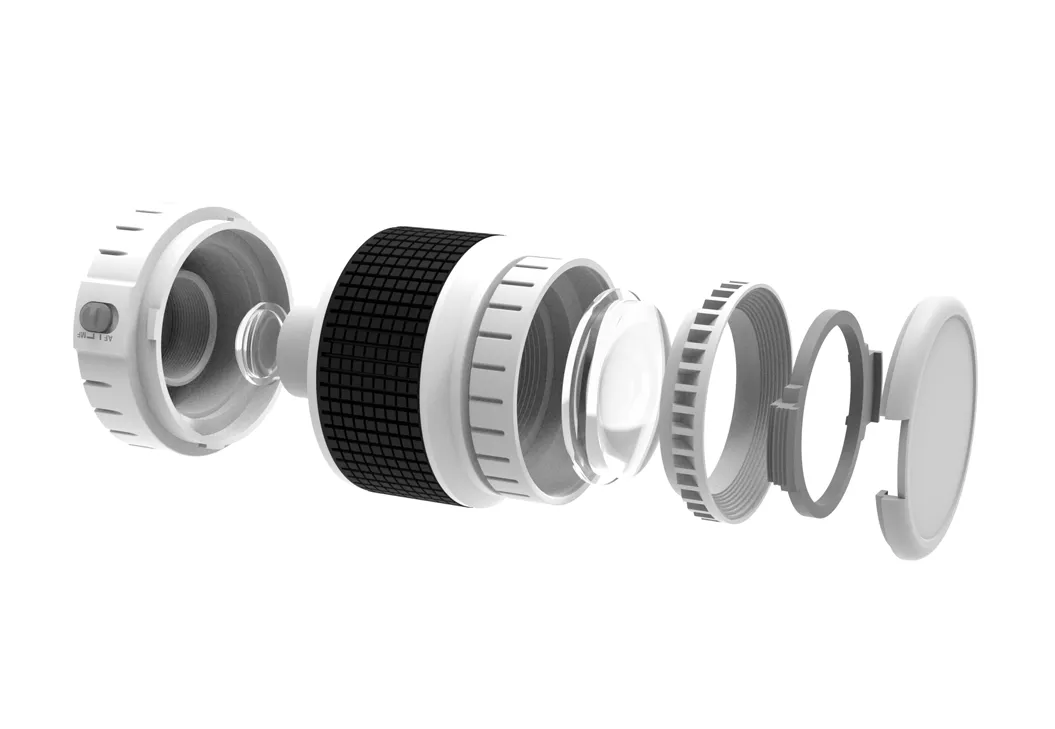

Impressive prototypes

The J35 Pro's PolyJet technology enables you to incorporate the widest variety of colors and materials into a single model. Create smooth, detailed prototypes that convey final-product aesthetics. Produce accurate jigs, fixtures, functional parts, concept models and more. Plus, achieve complex shapes, intricate details and delicate features.

J35 Pro Materials

The Stratasys J35 Pro can print three resins simultaneously, and provide multi-material capabilities that bring even the most imaginative ideas to life.

VeroUltra

VeroUltra WhiteS, VeroUltra BlackS, & VeroultraclearS

- Impressive contrast and color separation

- Smooth color transition

- Can be combined with various materials

- Superior capacity application

Potential applications:

- Toy & figurine production

- Consumer electronics

- Packaging

- Consumer goods

VERO

Realistic & Vibrant Colors

- Multi-purpose, multi-color family of materials | CMYKBWV

- Good stiffness and strength

- lend together or with other materials to change properties

Potential applications:

- Visually realistic prototypes

- Fit, form, and function prototypes

- Surgical models

- Jigs, fixtures, & tooling

Draftgrey

- Inexpensive

- Rigid material

- High-speed concept modeling

Potential applications:

- Early stage prototypes

- Concept modeling

- Design prototyping

Elastico

Clear & Black

- Rubber-like

- Tear-resistant

- Flexing and bending

Potential applications:

- Tooling

- Sporting goods

- General prototyping

Digital ABS Plus

Simulated ABS

- Most mechanically robust PolyJet material

- Combines temperature resistance with toughness

- Good impact strength

- 2 material blend

Potential applications:

- Design verification

- Functional testing

- Jigs & fixtures

- Manufacturing tooling

Stratasys J35 PRO 3D Printer Specifications

Model Materials

- VeroUltra™ ClearS

- VeroUltra™ BlackS

- VeroUltra™ WhiteS

- DraftGray™

- D-ABS Plus™

- Elastico™ Black

- Elastico™ Clear

- Vero™ ContactClear

Support Materials

SUP710™

WSS™ 150

Build Size

140 x 200 x 158mm

(5.51 x 7.87 x 6.22 in.)

Up to 1,174 cm²

Layer Thickness

Horizontal build layers down to 18 microns (0.0007 in.)

Workstation Compatibility

Network Connectivity

System Size and Weight

651 x 661 x 774mm* (25.63 x 26.02 x 30.48 in.); 98 kg (216 lbs.)

Operating Conditions

Temperature 18-25 °C (64-77 °F); relative humidity 30-70% (non-condensing)

Power Requirements

100–240 VAC, 50–60 Hz, 10A, 1 phase

Regulatory Compliance

CE, FCC, EAC, cTUVus, CB

Software

GrabCAD Print

Build Modes

High-Quality Speed: 18.75um

Accuracy

- Deviation from STL dimensions, for 1 Sigma (67%) of models printed with rigid materials, based on size: under 100 mm – ±150μ; above 100 mm – ±0.15% of part length.**

- Deviation from STL dimensions, for 2 Sigma (95%) of models printed with rigid materials, based on size: under 100 mm – ±180μ; above 100 mm – ±0.2% of part length.**

* The printable height is 158 mm and the max printable model height is 155 mm .

** Measured when ambient temperature is 23 °C and relative humidity is 50%.

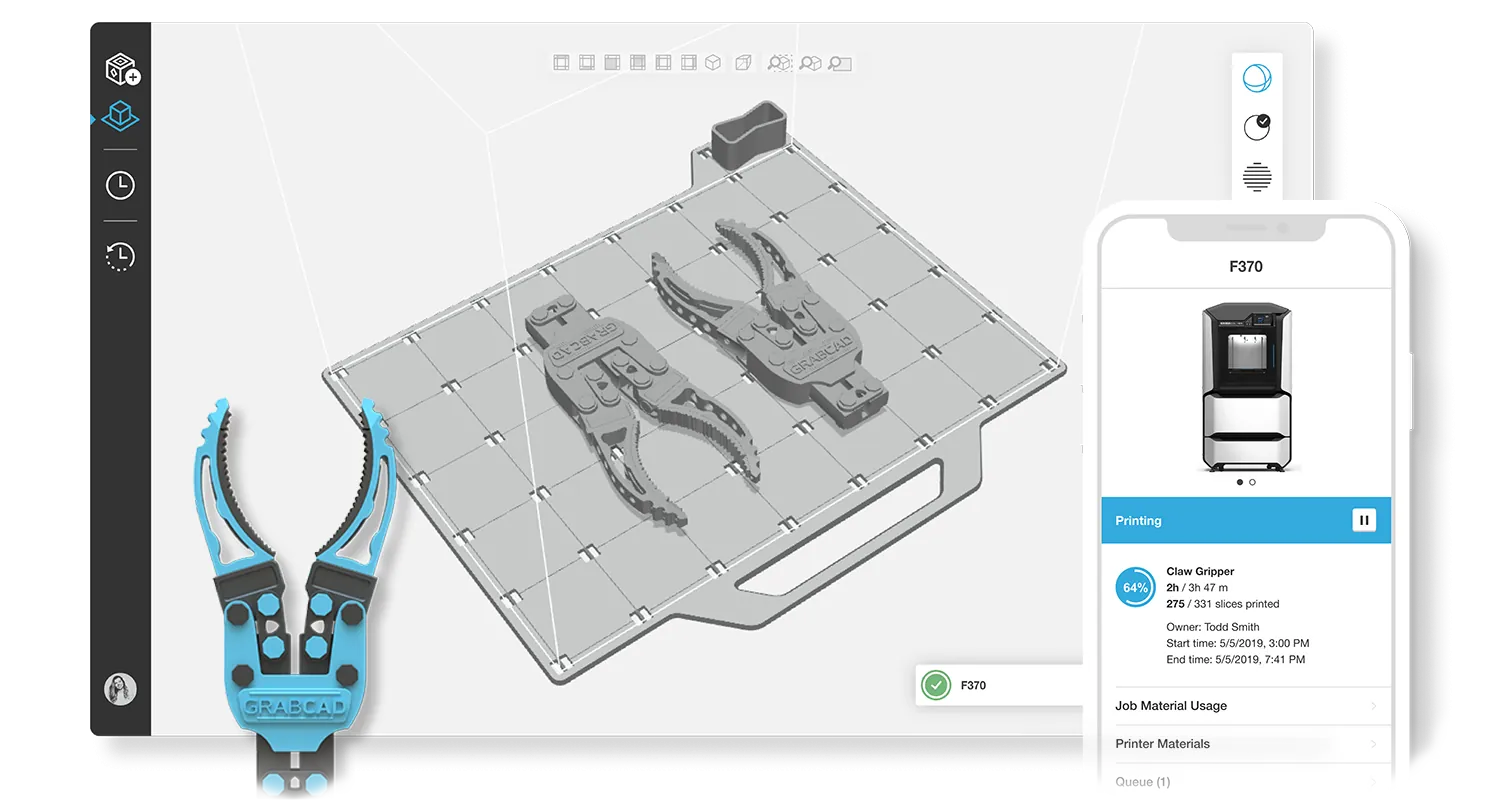

Software

GrabCAD Print

GrabCAD Print makes 3D printing easy, with thoughtful features:

- Automatically corrects files and reduces print time with automatic tray arrangement.

- Calculates the time and material resources needed for production before printing.

- 3MF file supported – significantly simplifies color assignment in your workflow.

- New feature alerts the user if there has been cross-contamination with a biocompatible material.

- Schedule and monitor the print job remotely from your mobile device or browser.

- Get automatic alerts remotely when the job is printing and finished.

ADDITIONAL 3D Printing RESOURCES

AWARD-WINNING TECHNICAL SUPPORT

GoEngineer’s extensive technical knowledge can assist with your additive manufacturing needs. Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

3D Printing Courses

Learn to utilize all features and tools of Stratasys commercial 3D printers with GoEngineer additive manufacturing on-boarding training and 3D printing courses. Take advantage of our 3D printing team of experts to help launch all your 3D printing capabilities.

3D PrintING SERVICES

No matter the size, quantity, or complexity of part(s) needed, GoEngineer can help you! Take advantage of our 3D Printing Services to help your organization produce the best parts and prototypes available on the market.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services