STRATASYS ORIGIN ONE

A High Output Resin 3D Printer

Now Serving US & Canada

Now Serving US & Canada

HIGH VOLUME 3D PRINTING. MADE POSSIBLE

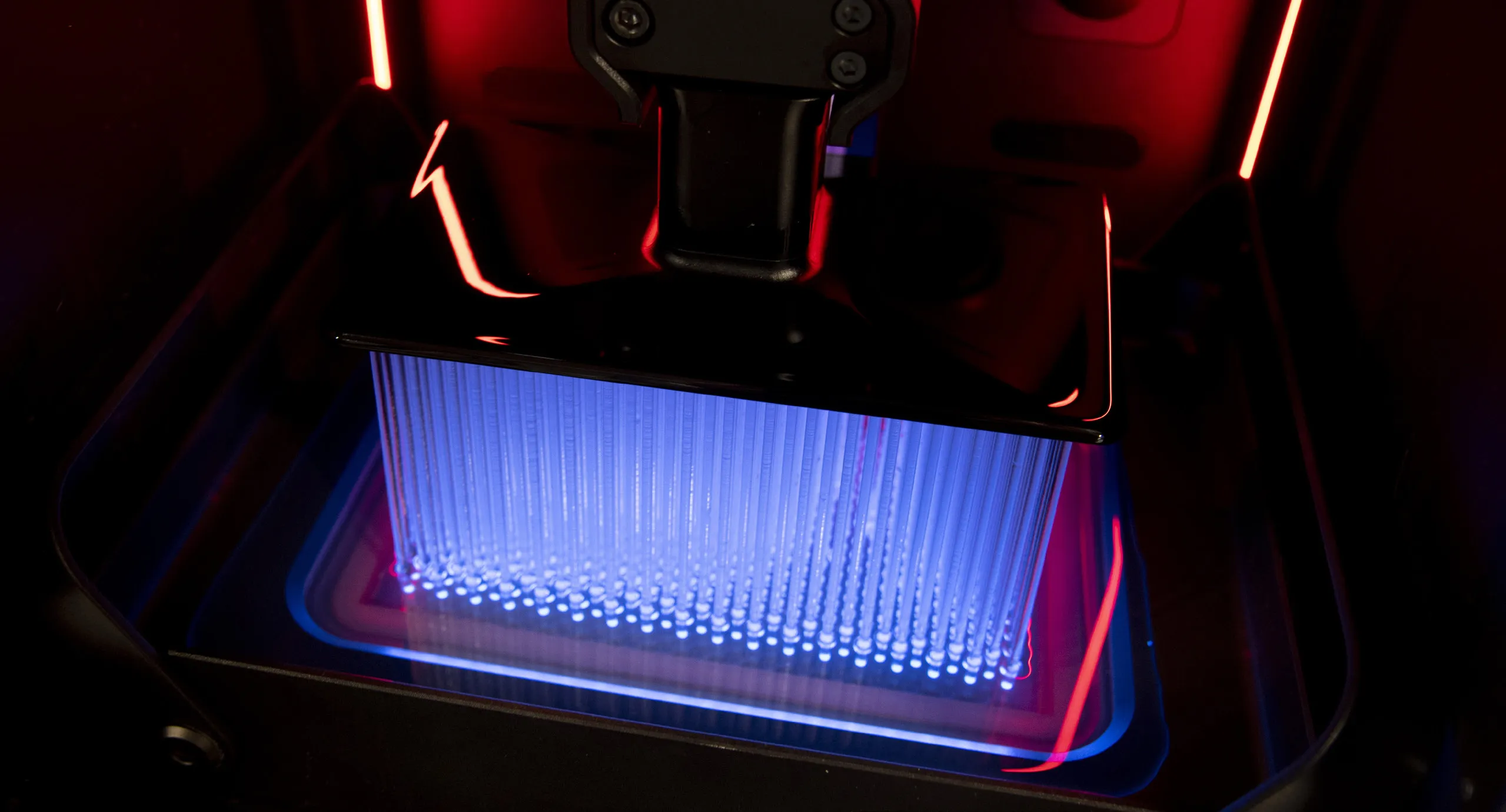

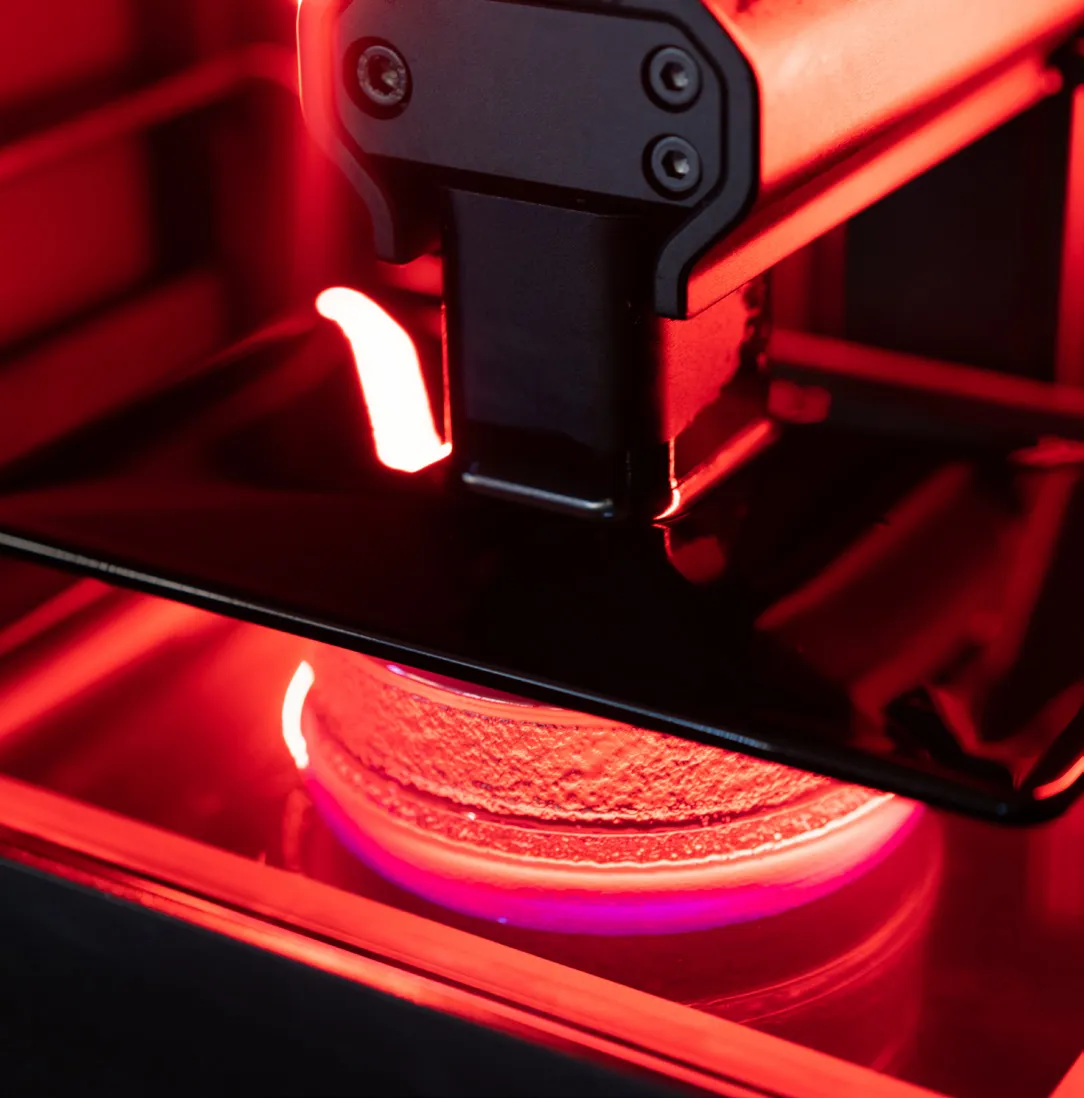

The Origin One is a powerful 3D printer that enables mass production in a range of high performance materials. Programmable PhotoPolymerization P3™ technology delivers industry leading accuracy, consistency, and details. Manage multiple machines with a single operation for high volume production.

don't miss the upcoming webinar!

Stratasys Origin One Dental: When Production Counts, Versatility Matters

Thu, Nov 10, at 12pm PT

Join us to learn about the latest in DLP technology: Origin One Dental from Stratasys.

Hear from power user Tra Chambers (Express Dental Laboratory) why he integrated this solution into his laboratory and how the Origin One Dental has transformed his laboratory’s digital workflow and production needs. We will also be joined by Ira Rosenau from Keystone Industries who will speak about the certified resins for Origin One Dental printer and the DLP development roadmap for new dental applications.

With Stratasys’ proprietary technology the Origin One Dental can ensure high accuracy and part to part consistency with the economical cost per part required by dental laboratories. Empower your dental laboratory to produce quality and highly accurate crown & bridge, implant and ortho models, nightguards and surgical guides, custom trays, dentures, all on x try-ins and more!

Features

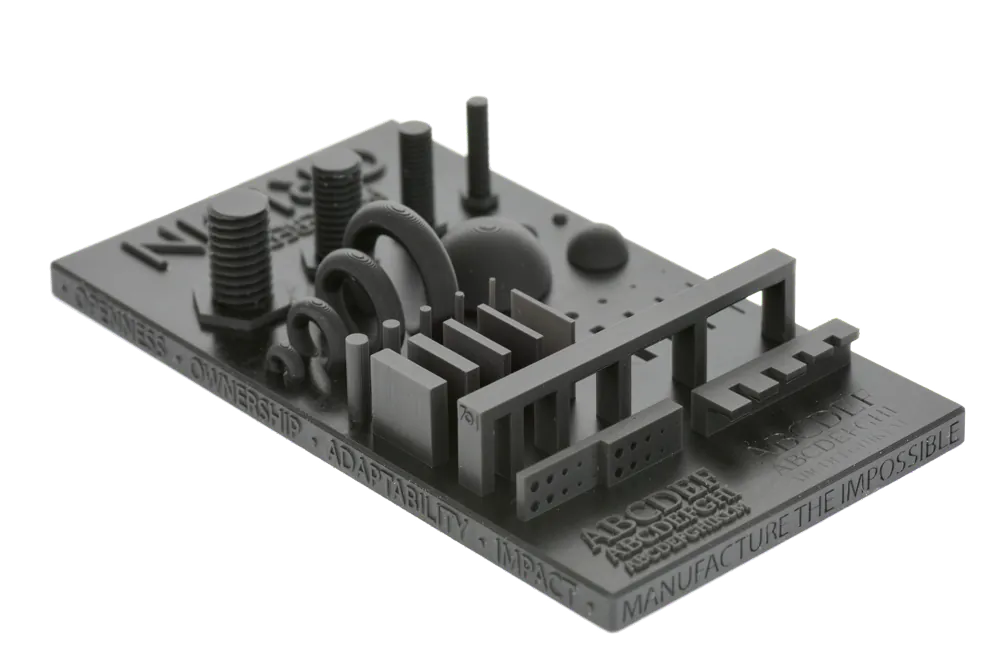

MASS PRODUCE ACCURACY

P3 Technology delivers superior accuracy, delivering print details less than 50 microns in size with high-accuracy materials. Even better, the smooth and beautiful surface quality of Origin One parts are attainable with no post-processing labor. Making the Origin One a unique manufacturing grade 3D printer, capable of bringing mass production to end-use parts.

NEXT-LEVEL PART PRODUCTION

Best-in-class repeatability, combined with high throughput, helps you expand production without delays. That means you can launch faster, and respond flexibly to shifts in demand, while maintaining minimal inventory.

CUTTING EDGE TECH, CONSTANT IMPROVEMENT

Programmable PhotoPolymerization P3™ technology allows for mass production with a diverse range of high performance materials, but we're just getting started. See powerful product improvements over time, with over-the-air software updates that unlock new advanced materials and workflow optimizations.

Origin One Materials

Available with: Stratasys Origin One 3D Printers

LOCTITE 3D 3955 FST

- High-performance, high-modulus, engineering material

- Extremely high HDT exceeding 300° C

-

Halogen-free and FST certified

- UL94 V-0 Flammability

- AITM2-0002, AITM2-0007, AITM3-0005

Potential applications:

- HVAC components

- Aerospace interior

- Automotive under the hood

- Precision connectors

- Electrical clips, plugs, housings

Available with: Stratasys Origin One 3D Printers

P3 Deflect 120

- High HDT temperature of 121° C

- Extremely h igh yield strength of 100 MPa

- High stiffness and hardness

- Easy to print

Potential applications:

- Under-the-hood components

- Blow molds

- Clips and brackets

- Functional parts

Available with: Stratasys Origin One 3D Printers

LOCTITE 3D IND403

- High HDT temperature of 80° C

- Machine and tappable

- Outstanding surface finish with minimal warping

- High yield strength of 70 MPa

Potential applications:

- Interior automotive components

- Tooling and molding

- Silicone molding and polyurethane casting

- Consumer products

Available with: Stratasys Origin One 3D Printers

Ultracur3D ST 45

- Quick printing and post processing

- High strength, hardness, and impact strength

- Biocompatible to ISO 10993 (cytotoxicity, irritation, sensitization)

- Flammability certified to UL94 HB

Potential applications:

- Highly detailed or textured parts

- Rapid prototyping & production

- Medical devices & prosthetics

- Housings & enclosures

Available with: Stratasys Origin One 3D Printers

LOCTITE 3D 3843

- High impact strength

- Semi-flexible

- Moderate HDT of 60 ° C

- Matte surface finish

- Biocompatible to ISO 10993-5/-23 (cytotoxicity, irritation, sensitization)

Potential applications:

- Consumer products

- Parts with Class A surfaces

- Automotive and industrial fabrication

- Medical device housing or parts

- Jigs & fixtures

Available with: Stratasys Origin One 3D Printers

Dura56

- Extremely low cost per part

- High impact resistance

- High energy absorption

- Matte surface finish

- Specifically formulated by Henkel for Stratasys

Potential applications:

- Functional testing/prototyping

- Jigs & Fixtures

- Class A mating surfaces

- Gadgets, toys, novelty items

- End-use production parts

Available with: Stratasys Origin One 3D Printers

LOCTITE 3D 3172

- Durable and tough

- Superior impact-resistance

- High energy absorption

- High elongation at break

- Machine, tap, and polish-able

Potential applications:

- Manufacturing Jigs & fixtures

- Sporting equipment

- Robotics & animatronics

- Insoles

- Topology oriented designs

Available with: Stratasys Origin One 3D Printers

Somos Weatherx 100

- UV, Weather, Temperature, & Chemical Resistant

- Easy and Fast Post-Processing

- Isotropic

- Durability

- Suitable for Challenging Geometries

Potential applications:

- Transportation / Outdoor Vehicles

- Industrial Equipment

- Consumer Goods

- Applications Exposed to UV and/or Humid Environments

Available with: Stratasys Origin One 3D Printers

LOCTITE 3D IND405

- High impact strength

- Over 125% elongation at break

- Excellent surface quality

- Optically transparent and clear

- Low UV degradation and yellowing

- Biocompatible options available

Potential applications:

- Mechanical guides

- Fluid ducts

- Microfluidic devices & guide overlays

- Light pipe and packaging prototypes

Available with: Stratasys Origin One 3D Printers

LOCTITE 3D IND402

-

True elastomeric behavior

- 230% elongation at UTS

- Shore hardness of 76A

- Excellent interlayer adhesion

- High energy absorption

- Minimal plastic deformation

Potential applications:

- Engineered lattice structures

- Sporting equipment

- Insoles and handgrips

- Gaskets, tubing, & hoses

- Ergonomic or soft touch items

Available with: Stratasys Origin One 3D Printers

P3 Stretch IND475

- True elastomeric behavior

-

- 122 % elongation at UTS

- Shore hardness of 49 A

- 77% energy return

- Minimal shrinkage

- High resilience

- Easy to print and process

Potential applications:

- Air and dust gaskets

- Flexible seals and housings

- Cushioning pads

- Soft grippers for EOT

- Silicone-like parts

Available with: Stratasys Origin One 3D Printers

LOCTITE 3D MED412

- Medical-grade certified

- Durable with flexibility

- Sterilizable

- Biocompatible to ISO 10993-5/-10 (cytotoxicity, irritation, sensitization)

Potential applications:

- Test swabs

- Single-use medical instruments

- Class I and II medical devices

- Lab equipment

- Covers and guards

Available with: Stratasys Origin One 3D Printers

LOCTITE 3D MED413

- Medical-grade certified

- Stiff and tough

- Outstanding surface finish

- High HDT of 70° C

- Sterilizable

- Biocompatible to ISO 10993-5/-10 (cytotoxicity, irritation, sensitization)

Potential applications:

- Orthotics

- Durable and reusable medical components

- Hearing aids

- Respirator components

ORIGIN ONE Specifications

TECHNOLOGY

- Programmable PhotoPolymerization P3™

MATERIALS

- Photocurable materials from Stratasys ecosystem material partners. Refer to the Stratasys website for an up-to-date selection.

BUILD ENVELOPE

- 192 x 108 x 370 mm / 7,672 cm 3

- (7.5 x 4.25 x 14.5 in. / 462 in 3 )

- Maximum length on the diagonal — 220mm (8.6 in.)

MINIMUM FEATURE SIZE

- Material and design dependent, as low as 50μm

Process ENERGY

- UV (385nm) and thermal

SOFTWARE

- Origin One cloud based web application

REGULATORY COMPLIANCE

- CE, FCC

SYSTEM SIZE AND WEIGHT

- 49 x 51 x 113cm (19 x 20 x 44 in.)

- 81 kg (180 lbs.)

Power Requirements

- 90–264 VAC, 50–60 HZ, 700 W, 1 phase

OPERATING CONDITIONS

-

Operating temperature 15°C to 30°C (59°F to 86°F)

- Operating Humidity 30% to 70%

RESIN TRAY CAPACITY

- 2L

RESIN STORAGE TEMP

- Typically 15°C to 30°C (59°F to 86°F)

Software

GrabCAD Voxel

Unleash the power of the voxel. In combination with PolyJet Studio and GrabCAD Print, now experience GrabCAD Voxel Print for limitless color and material capabilities at the voxel level.

- PolyJet Studio’s intuitive interface makes it easy to choose materials and optimize the build and print queues.

- GrabCAD Print software makes 3D printing on Stratasys 3D Printers easy, accessible, and connected. The software’s efficient workflow streamlines job management in shared office and model shop environments.

- GrabCAD Voxel Print delivers unprecedented user control over color and material placement.

Origin One Dental

Stratasys Origin ONe Dental 3D printer

The Origin One Dental 3D printer is capable of producing manufacturing-grade dental models, splints, and surgical guides with consistency and accuracy every single time. Cutting-edge materials from industry-leading partners paired with user-friendly and quick to learn software, Stratasys’ Origin One Dental 3D printer is a solution you can count on.

ADDITIONAL 3D Printing RESOURCES

AWARD-WINNING TECHNICAL SUPPORT

GoEngineer’s extensive technical knowledge can assist with your additive manufacturing needs. Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

3D Printing Courses

Learn to utilize all features and tools of Stratasys commercial 3D printers with GoEngineer additive manufacturing on-boarding training and 3D printing courses. Take advantage of our 3D printing team of experts to help launch all your 3D printing capabilities.

3D PrintING SERVICES

No matter the size, quantity, or complexity of part(s) needed, GoEngineer can help you! Take advantage of our 3D Printing Services to help your organization produce the best parts and prototypes available on the market.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services