STRATASYS H350 3D Printer

A High Volume SAF 3D Printer

Now Serving US & Canada

Now Serving US & Canada

MEET DEMAND WITH A high production powerhouse

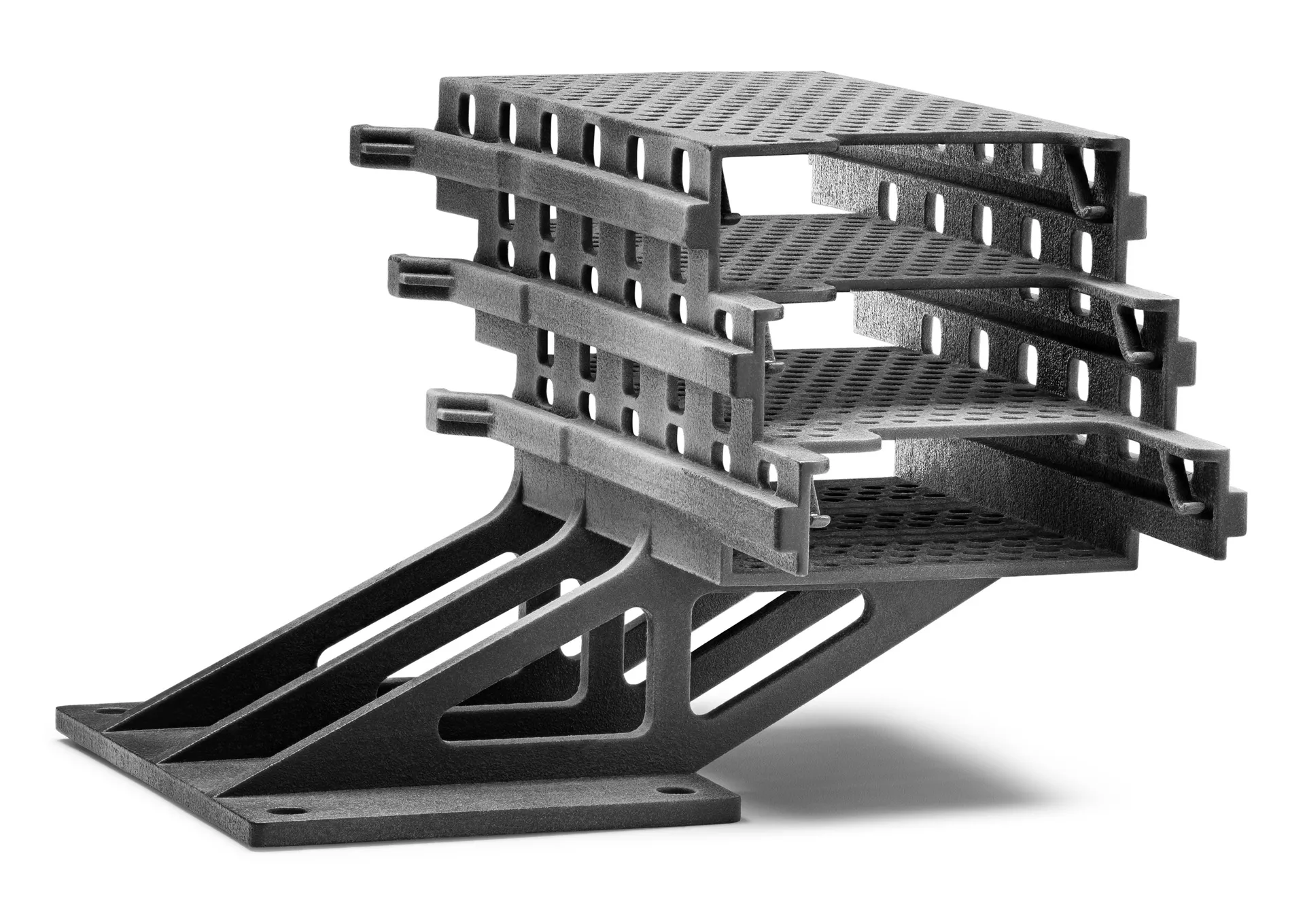

The Stratasys H350 is a powder bed fusion 3D printer built to meet intense production demand. Designed for high volume, short-run production, the H350 gives you control over materials, workflow and cost. The unique SAF technology produces parts with startling accuracy and repeatability.

MEET THE STRATASYS H SERIES

The Stratasys H350 is the first release of the H Series™ production platform, which has Selective Absorption Fusion™ SAF™ technology at its heart to deliver functional, production grade parts with best-in-class consistency.

Features

TAKE CONTROL OF YOUR WORKFLOW

The Stratasys H350 allows teams the freedom to choose their build preparation software platform to best suit their needs. The unique workflow puts you in complete control of build data and powder quality management, so you can ensure each batch meets your specifications. Few consumables, easy upkeep, and dependable industrial quality components, ensure freedom without frustration.

CUT OUT HIDDEN PRINT COSTS

SAF technology utilizes a single fusing fluid, which means your cost per part is predictable and straightforward. Industrial grade print heads means you never bear replacements cost, instead the long-lasting components are non-consumable and included as part of your service contract. Even unfused powder can be reused to minimize material cost and reduce your cost per part.

PEAK ACCURACY, TIME AFTER TIME

The SAF Technology at the heart of the H350 produces repeatable and accurate parts at high-volume. Count on reliable details from flat areas and large parts, to the finest features.

h350 Materials

saf pa11

High Yield Production grade polymer

- High ductility and impact resistance

- Made from 100% bio-based castor oil

- Smooth finish quality

- Strong and durable

Potential applications:

- End-use products

- Hinges

- Housings and covers

- Load bearing parts

saf pa12

Durable Production grade polymer

- Higher stiffness

- Improved heat deflection and chemical resistance

- Derived from crude oil

Potential applications:

- Automotive applications

- Machine components

- Consumer goods

SAF TECHNOLOGY

The Stratasys H350 jets single or multiple drops of High Absorbing Fluid to produce fine detail or large fused areas without compromising throughput. Thanks to its unique in-line, unidirectional architecture, SAF technology prints, fuses, recoats (with Big Wave powder system) and powder heats in the same direction.

Key benefits of SAF 3D printing include

- Highly accurate, end use parts

- Predictable and competitive print cost

- Consistent repeatability

- Produce numerous parts in a single batch

STRATASYS H350 Specifications

Build Size

- XYZ : 315 x 208 x 293 mm (12.40 x 8.18 x 11.53 in)

- Volume : 19.2 l (5.07 gallon)

Layer Thickness

- 100 μ (0.004 in)

TIME TO A FULL BUILD

- 11.62 hrs.

Power

- Requirements : 400VAC, 3P+N, PE, 50-60 Hz, 16A

- Consumption : 3.25 kw, 5 kw (peak), 0.15 kw (Idle)

OPERATING CONDITIONS

- Temperature : 20-25˚ C (68-77 deg F)

- Humidity : [40-55]% RH

- Extraction rate : 300 m3/h (294 CFM)

SYSTEM SIZE AND WEIGHT

- 1900 x 940 x 1730 mm (74.8 x 37.0 x 68.1 in) and 825 kg (1819 lbs)

CONNECTIVITY

- RJ45 Ethernet connection 35MBit

- Network with DHCP server and internet access

Power Requirements

- 90–264 VAC, 50–60 HZ, 700 W, 1 phase

SUPPORTED SOFTWARE WORKFLOW

- Materialise Magics, Siemens NX and PTC Creo

- GrabCAD Print Pro

MATERIALS

- Powder : Stratasys High Yield PA11, SAF™, PA12, SAF PP™

- Fluid : Stratasys High Absorption Fluid HAF TM

Software

GrabCAD Voxel

Unleash the power of the voxel. In combination with PolyJet Studio and GrabCAD Print, now experience GrabCAD Voxel Print for limitless color and material capabilities at the voxel level.

- PolyJet Studio’s intuitive interface makes it easy to choose materials and optimize the build and print queues.

- GrabCAD Print software makes 3D printing on Stratasys 3D Printers easy, accessible, and connected. The software’s efficient workflow streamlines job management in shared office and model shop environments.

- GrabCAD Voxel Print delivers unprecedented user control over color and material placement.

ADDITIONAL 3D Printing RESOURCES

AWARD-WINNING TECHNICAL SUPPORT

GoEngineer’s extensive technical knowledge can assist with your additive manufacturing needs. Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

3D Printing Courses

Learn to utilize all features and tools of Stratasys commercial 3D printers with GoEngineer additive manufacturing on-boarding training and 3D printing courses. Take advantage of our 3D printing team of experts to help launch all your 3D printing capabilities.

3D PrintING SERVICES

No matter the size, quantity, or complexity of part(s) needed, GoEngineer can help you! Take advantage of our 3D Printing Services to help your organization produce the best parts and prototypes available on the market.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services