Creaform MetraSCAN 3D

Optical CMM scanner metrology-grade measurement system

What is Creaform’s Metrascan System?

The MetraSCAN 3D™ optical CMM scanner is the ideal solution for shop-floor inspection or reverse-engineering needs. At the core of the Creaform optical CMM is the C Track optical tracker with its ability to perform real-time dynamic referencing of the MetraSCAN and HandyPROBE devices as well as targets on a part. Built with high-end optical components, the C-Track drives the metrology-grade measurements of the whole system.

Scanning and Probing support

One of the most powerful advantages of a metrology-grade measurement system is the ability to both scan and take contact or optical probe measurements, providing versatility of use. The system’s scanning and probing capabilities can be used independently or integrated into the measurement workflow.

Extendable Measurement Volume

Flexible measurement volume allows the user to move the C Track and measured part dynamically to capture all the required data instead of a rigid setup that would limit the amount of data collection and require leapfrogs, potentially adding the loss of accuracy between moves.

ADD-ONS

Max Shot 3D Photogrammetry. Creaform’s Max Shot 3D System can be integrated for product development, manufacturing, quality control, and inspection teams that need the highest measurement accuracy and repeatability as much for large scale projects than for parts from 2 to 10 m. achieving an accuracy of 0.015mm/m or better.

MetraSCAN Features

Dynamic Referencing

The Dynamic Referencing capability allows for freedom of movement without the necessity of having a rigid setup. The C-Track tracks the targets in its 16.6m^3 volume in real-time allowing for vibrations commonly found on shop floor environments. This also allows for the C-Track to move around the part and extend the volume by acquiring additional targets to the scene or working volume. This amounts to greater flexibility in the setup of the measurement workflow which leads to substantial time and cost savings.

ACCESSORIES

The Creaform Shop-Floor Workstation is designed to ensure optimal manufacturing performance when using Creaform’s dimensional inspection devices in production environments. It incorporates all the tools you need in one workstation and offers secure storage for all Creaform 3D measurement technologies (portable 3D scanners, portable CMM, photogrammetry system, and related accessories). By adding flexibility, mobility, and reliability to Creaform’s systems across a production plant while being in operation, the workstation improves efficiency, productivity, and the overall quality assurance process on the shop floor.

Stand-alone or bundled with the workstation, the C-Track Shop-Floor Stand facilitates the mobility of the C-Track around the part to be inspected while running. Once mounted on the stand’s extendable pole, the C-Track dual-camera sensors can reach a height of 1.9 m (73 in.) to accommodate high and low inspection set-ups. Also fitted with locking wheels and retractable legs, the stand can easily adapt to static use. Paired with the Self-Power Kit (external battery), move the C-Track Shop-floor Stand from one place to another without worrying about temperature stabilization time when shutting down/restarting the C-Track and controller. Along with the workstation, it provides a complete solution for a real-time manufacturing quality control process.

SPECIFICATIONS

METRASCAN™ |

METRASCAN™|ELITE |

||

| Accuracy | 0.025 mm (0.0009 in) | ||

| Volumetric Accuracy | 9.1 m3 (320 ft3) (3) | ||

| 16.6 m3 (586 ft3) (3) | |||

| Volumetric Accuracy (with MaxSHOT 3D or C-Link) | MaxSHOT Next™ | (0.0024 in + 0.0003 in/ft) |

(0.0017 in + 0.0003 in/ft) |

| MaxSHOT Next™|Elite | (0.0024 in + 0.00018 in/ft) |

(0.0017 in + 0.00018 in/ft) |

|

| Resolution | |||

| Measurement Rate | |||

| Part Size Range (recommended) | |||

| Stand-off Distance | |||

| Depth-of-field | |||

| Scanning Area | |||

| Light Source | |||

| Laser Class | |||

| Weight | Probe: 0.5 kg (1.1 lb) C-Track: 5.7 kg (12.5 lb) |

||

| Dimensions | |||

| Connection Standard | |||

| Software | |||

| Output Formats | |||

| Operating Temperature Range | |||

| Operating Humidity Range (non-condensing) | |||

| Certifications | |||

| Patents | US 10,271,039, JP 6,596,433, CA 2,938,104, KR 10-2424135, EP (FR, UK, DE) 3,102,908, CA 3,166,558 | ||

Software

No matter your application, GoEngineer has a specific 3D Scanning software to fit your needs.

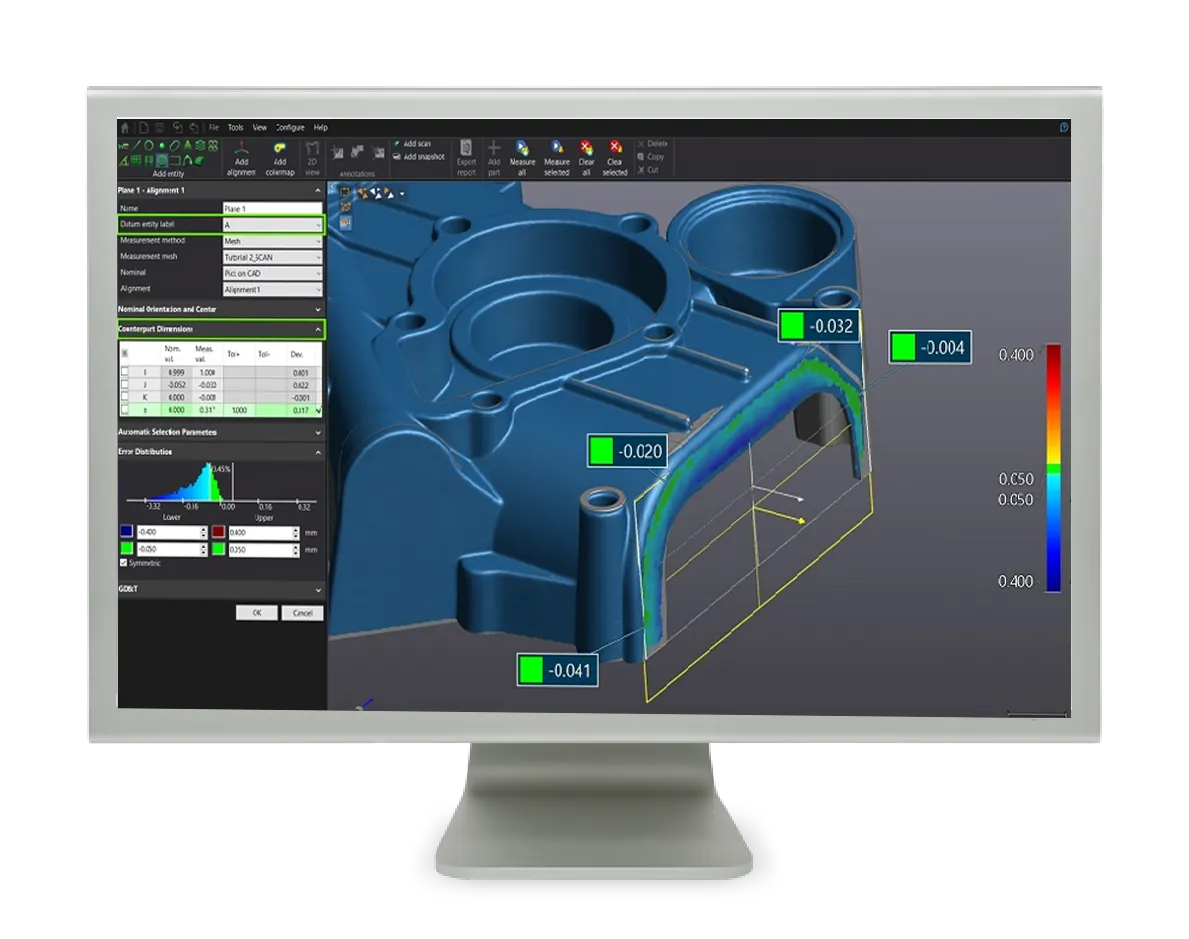

VXELEMENTS

3D SCANNING SOFTWARE PLATFORM

Creaform’s VXelements provides a fully integrated 3D software platform that powers the entire fleet of 3D scanning and measurement technologies. It gathers all the essential elements (VXscan, VXprobe, VXshot) and tools into a user-friendly, simple, and sleek working environment.

ADDITIONAL Software

REVERSE ENGINEERING

Creaform VXModel

GeoMagic Design X

GeoMagic for SOLIDWORKS

GeoMagic Wrap

INSPECTION

Frequently Asked Questions

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services