Creaform Go!SCAN Spark

Fast and Accurate Structured Light 3D Scanning

Do You need simplified, quick, and accurate 3D scanning?

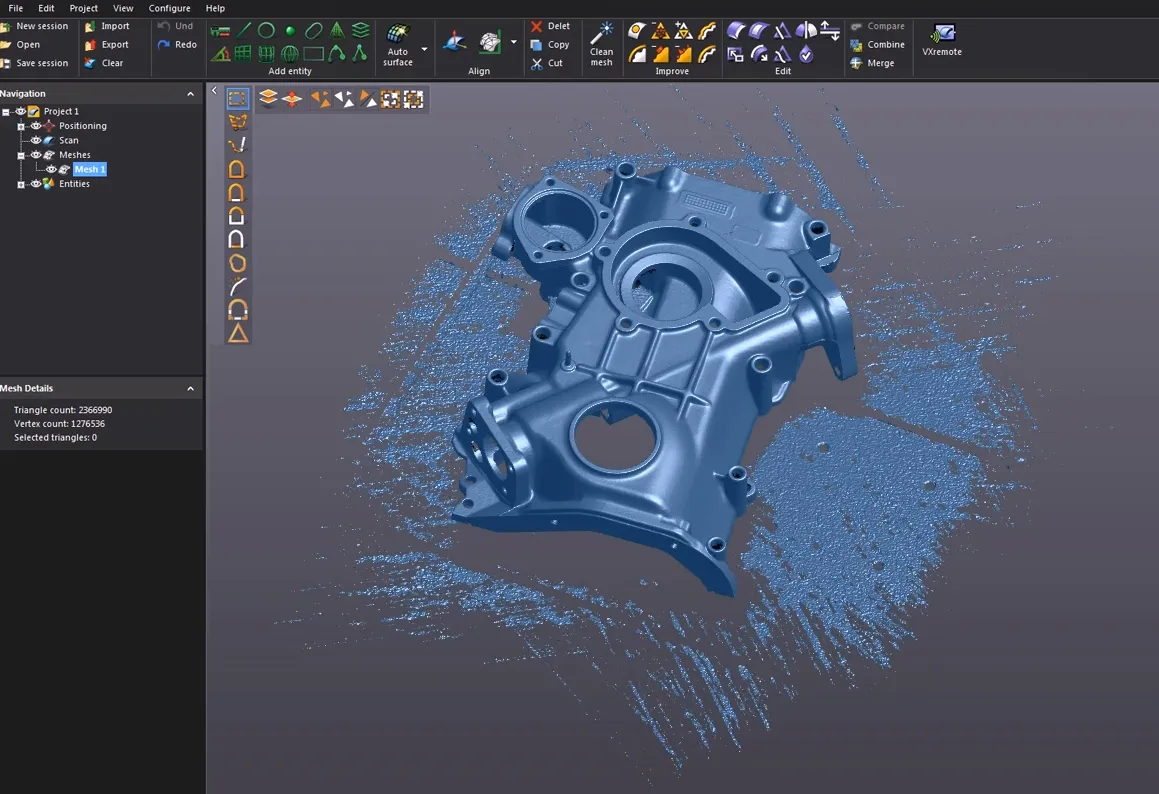

The Go!SCAN Spark is the latest in color 3D scanning technology from Creaform. It is a structured light scanner with very quick and accurate data capture. The scanner is completely handheld and does not require the use of an arm or tripod. Set up takes just minutes and you are up and running! The ergonomic design and being lightweight make a great scanner for reverse engineering. Along with the VXelements software, scan data processing is a breeze.

Color Acquisition

Capture vibrant color 3D scan data with up to 200 DPI. The camera's automatic shutter speed allows you to scan multi-color parts with ease and export the texture at any time in various formats. If you don't want to capture texture, simply check the box to turn it off.

Accuracy & Resolution

The Go!SCAN Spark has a surface accuracy of (.002”). The volumetric accuracy of the scanner is (.0018”) per running foot which determines how close your scan is to the part in the X, Y, and Z axis. The resolution of the scanner is (.0039”).

Portable

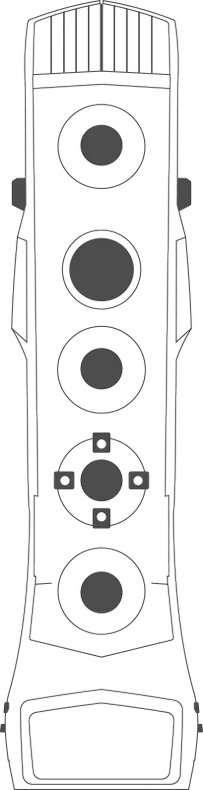

Weighing in at just 2.7 lbs., this scanner and its additional hardware is travel friendly and is compact enough that it can fit into a standard size briefcase.

GO!SCAN SPARK Features

Self-Tracking

Start scanning from anywhere without part preparation! The Go!SCAN Spark doesn't require targets (but are available if desired) and instead tracks off of natural features to position data. If a human being or other living creature is being scanned, there are additional options for semi-rigid objects that assist with scanning objects that can't keep completely still. If for any reason tracking is lost, the “resume -scan” option will help you pick up right where you left off.scanning from anywhere without part preparation! The Go!SCAN Spark doesn't require targets (but are available if desired) and instead tracks off of natural features to position data. If a human being or other living creature is being scanned, there are additional options for semi-rigid objects that assist with scanning objects that can't keep completely still. If for any reason tracking is lost, the “resume -scan” option will help you pick up right where you left off.scanning from anywhere without part preparation! The Go!SCAN Spark doesn't require targets (but are available if desired) and instead tracks off of natural features to position data. If a human being or other living creature is being scanned, there are additional options for semi-rigid objects that assist with scanning objects that can't keep completely still. If for any reason tracking is lost, the “resume -scan” option will help you pick up right where you left off.

![]()

Instant Mesh

VXelements is the data capture software used with the Go!SCAN Spark 3D Scanner. This software automatically aligns all of your scan frames to create a single mesh once the scan is finalized and regardless of whether or not it contains texture. If you notice a misalignment there is an option to delete frames.

Smart Controls

The Go!SCAN Spark has several built-in smart controls that can be accessed while you are away from your laptop including buttons for starting a stopping a scan. Users can zoom in/out or lock a viewpoint as well as select "fit to screen" if zoomed too far accidentally. Calibration and shutter speed settings can be accessed directly from the scanner and smart controls save the scan when complete. LED lights on either side of the scanner display stand-off distance.

SPECIFICATIONS

| Volumetric accuracy with MaxSHOT Next™ | Elite (3 | Up to 0.050 mm | (0.0020 in) | |||||||||

| Volumetric accuracy with MaxSHOT Next™ | Elite (3 | 0.050 mm + 0.150 mm/m | (0.0020 in + 0.0018 in/ft) | |||||||||

| Volumetric accuracy with MaxSHOT Next™ | Elite (3) | 0.050 mm + 0.015 mm/m | (0.0020 in + 0.00018 in/ft) | |||||||||

| Measurement resolution | 0.100 mm | (0.0039 in) | |||||||||

| Mesh resolution | 0.200 mm | (0.0078 in) | |||||||||

| Measurement rate | 1,500,000 measurements/s | |||||||||

| Light source | White light (99 stripes) | |||||||||

| Positioning methods | Geometry and/or color and/or targets | |||||||||

| Scanning area | 390 x 390 mm | (15.4 x 15.4 in) | |||||||||

| Stand-off distance | 400 mm | (15.7 in) | |||||||||

| Depth of field | 450 mm (17.7 in) | |||||||||

| Part size range (recommended) | 0.1–4 m | (0.3–13 ft) | |||||||||

| Texture resolution | 50 to 200 DPI | |||||||||

| Texture colors | 24 bits | |||||||||

| Software | VXelements | |||||||||

| Output formats | .dae, .fbx, .ma, .obj, .stl, .txt, .wrl, .x3d, .zpr, .3mf | |||||||||

| Patents |

CA 2,600,926, CN 200680014069.3, US 7,912,673, EP (FR, UK, DE) 1,877,726, AU 2006222458, US 8,032,327, JP 4,871,352, EP (FR, UK, DE) 2,278,271, IN 266,573, US 7,487,063, CA 2,529,044, CA 2,810,587, US 8,836,766, JP 5,635,218, CA 2,875,754, EP (FR, UK, DE) 2,751,521, US 9,325,974, CA 2,835,306, CN 201280023545.3, CN 201280049264.5, JP 6,025,830, EP (FR, UK, DE) 2,875,314, CN ZL 201380029999.6, JP 6,267,700, EP (FR, UK, DE) 3,102,908, US 15/114,563, CN 201580007340X |

|||||||||

| Weight | 1.25 kg (2.7 lb) | |||||||||

| Dimensions- (LxWxH) | 89 x 114 x 346 mm | (3.5 x 4.5 x 13.6 in) | |||||||||

| Connection standard | 1 X USB 3.0 | |||||||||

| Operating temperature range | 5-40 °C | (41-104 °F) | |||||||||

| Operating humidity range (non-condensing) |

10-90% | |||||||||

| Certifications | EC Compliance (Electromagnetic Compatibility Directive, Low Voltage Directive), compatible with rechargeable batteries (when applicable), IP50, WEEE | |||||||||

| Certifications |

EC Compliance (Electromagnetic Compatibility Directive, Low Voltage Directive), compatible with rechargeable batteries (when applicable), IP50, WEEE

(1) Typical value for diameter measurement on a calibrated sphere artefact. (2) Performance with positioning targets or with an object presenting adequate geometry/color texture for positioning. Performance is assessed with traceable length artefacts using positioning targets. (3) The volumetric accuracy of the system when using a MaxSHOT 3D cannot be superior to the default volumetric accuracy. |

|||||||||

Software

No matter your application, GoEngineer has a specific 3D scanning software to fit your needs.

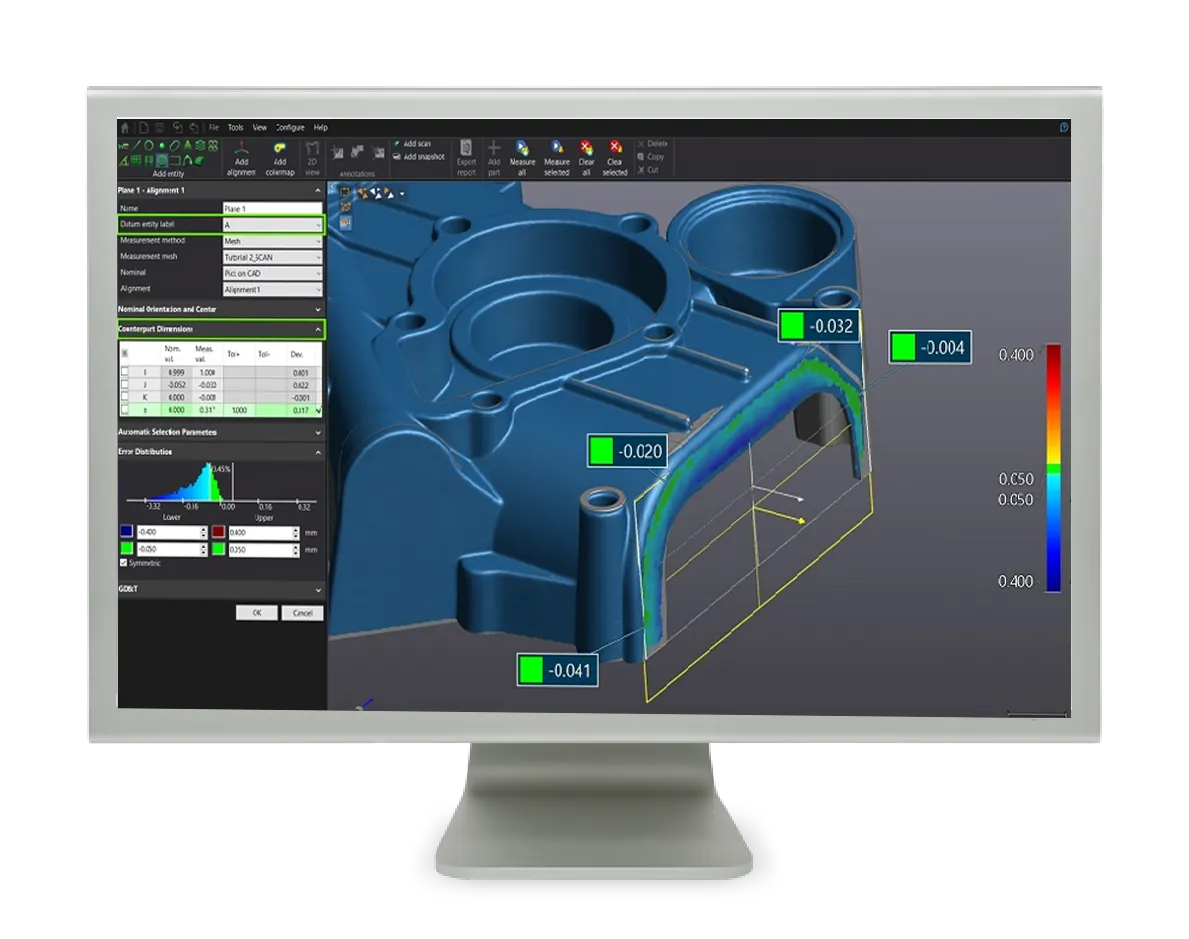

VXELEMENTS

3D SCANNING SOFTWARE PLATFORM

Creaform’s VXelements provides a fully integrated 3D software platform that powers the entire fleet of 3D scanning and measurement technologies. It gathers all the essential elements (VXscan, VXprobe, VXshot) and tools into a user-friendly, simple and sleek working environment.

ADDITIONAL Software

REVERSE ENGINEERING

Creaform VXModel

GeoMagic Design X

GeoMagic for SOLIDWORKS

GeoMagic Wrap

INSPECTION

Frequently Asked Questions

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services