Creaform 3D Scanners

Portable 3D Scanning Technologies

Fast and Versatile 3D Scanners

Together with Creaform, GoEngineer offers a variety of portable 3D scanning technologies that have been developed to meet the specific needs of a wide range of applications including aerospace, automotive, and oil & gas industries. From professional-grade to metrology-grade, they provide users with highly accurate, portable, and easy-to-use solutions.

Creaform 3D Scanners deliver accurate, high-resolution, and repeatable results, regardless of the measurement setup quality or user experience. Featuring dynamic referencing, both the scanner and part can move during measurement and still provide an accurate and high‑quality scan.

don't miss this upcoming webinar!

Solving Productivity Issues Through 3D Scanning - Deciding between Handheld and Automated 3D Scanning

April 13, 2022 at 10am PT

In webinar Jerome-Alexandre Lavoie, Product Manager at Creaform, will present tools that will help manufacturing companies analyze whether automation is more suitable for their activities than handheld 3D scanning. To better understand the potential of transitioning to automation and show how robot programming is accessible to everyone, Olivier Plamondon, Technical Product Manager at Creaform, will go through a complete automated quality control project in a live demonstration. To round off this webinar, Kyle Shannon, Business Development Manager A-QC at Creaform, will discuss the cost-benefit of transitioning to automation, and the expected return on investment.

Join Creaform’s experts and discover which handheld or automated 3D scanning solution is right for YOUR workflow.

BENEFITS

Very simple 3D scanning process

The straightforward data acquisition process generates extra fast results, with real-time visualization and direct mesh output. These 3D scanners are up and running in less than five minutes and require no rigid setup or prior experience from the user. You can scan parts in virtually any size, material, or color.

3D scanning where you need to go

Our 3D scanners are handheld, light, and they fit into a small suitcase. Because they have no mechanical constraint, they allow total freedom of movement and can be brought and used virtually anywhere.

Accurate measurements in real-life conditions

Creaform 3D Scanners ensure highly-accurate measurements, regardless of the environment (instability, vibrations, thermal variation, etc.) or operator skills. Our scanners use software algorithms that simplify the measurement process and greatly increase data accuracy.

Creaform 3D SCANNERS

-

-

Go!SCAN 3D

- Accuracy:

0.050 mm (0.0020 in) - Resolution:

0.100 mm (0.0039 in) -

Features:

Structured White LED Light

-

-

HandySCAN 3D

- Accuracy:

Up to 0.075 mm (0.0030 in) - Resolution:

0.025 mm (0.0009 in) -

Features:

Blue & Red Laser High Resolution

Add-On Hardware

MaxSHOT 3d

Large-scale metrology projects

- Automatic feedback on measurement quality

- Designed specifically for photogrammetric applications

- 50% lighter than traditional photogrammetric devices

3D Scanning Case Studies

AADS specializes in the design, manufacturing of specialized Jeep vehicles for governmental organizations. AADS uses their Go!Scan Spark scanner to reverse engineer and validate custom parts.

Creaform 3D scanners are handheld and are non-contact. This versatility enables 3D technology to support four preservation categories: 3D archives, virtual museums, restoration, and preservation.

Plastic blow molding company Blowtech reduced their process time by 50% with 3D scanning. Originally the company had to ship the parts to an external service partner for inspections.

Software

No matter your application, GoEngineer has a specific 3D scanning software to fit your needs.

VXELEMENTS

3D SCANNING SOFTWARE PLATFORM

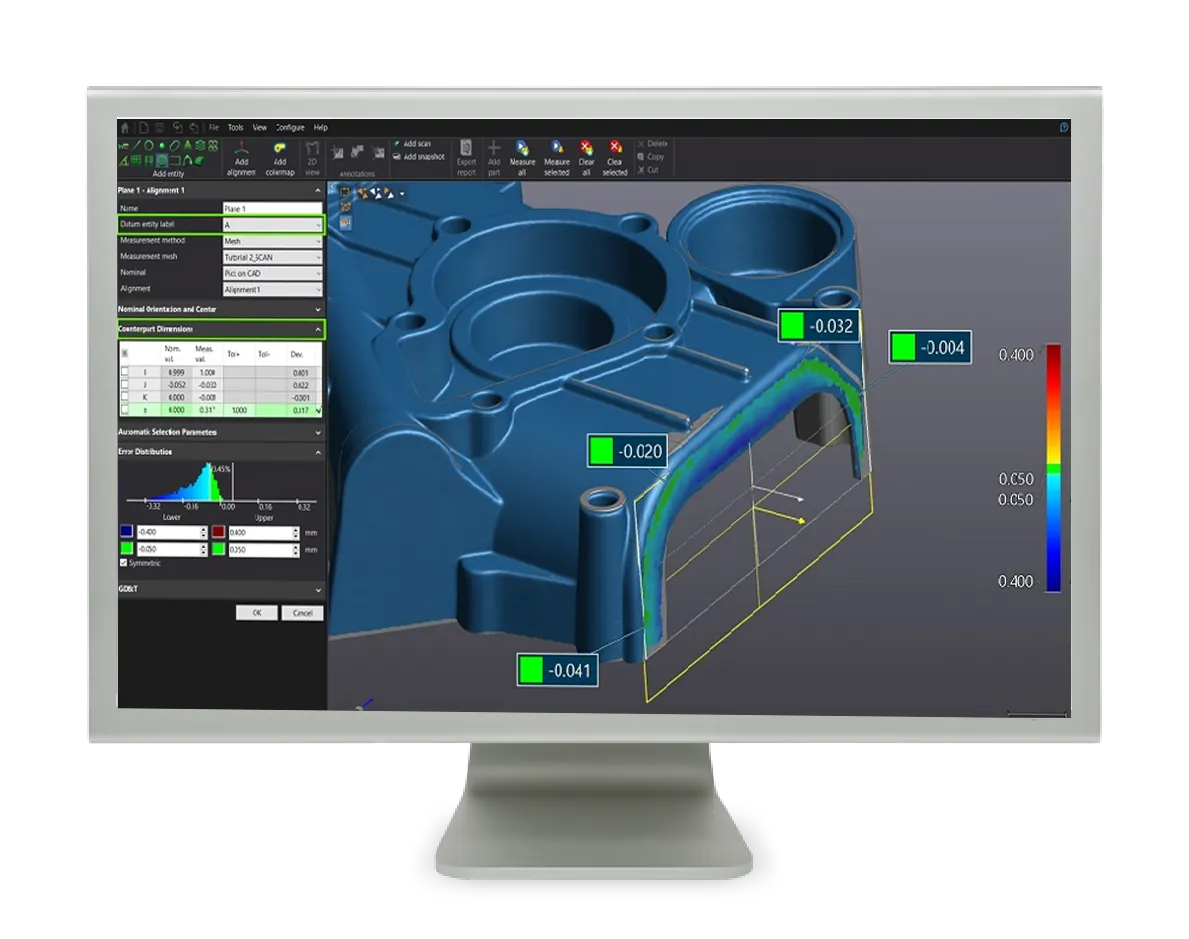

Creaform’s VXelements provides a fully integrated 3D software platform that powers the entire fleet of 3D scanning and measurement technologies. It gathers all the essential elements (VXscan, VXprobe, VXshot) and tools into a user-friendly, simple and sleek working environment.

ADDITIONAL Software

REVERSE ENGINEERING

Creaform VXModel

Geomagic Design X

Geomagic for SOLIDWORKS

Geomagic Wrap

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services