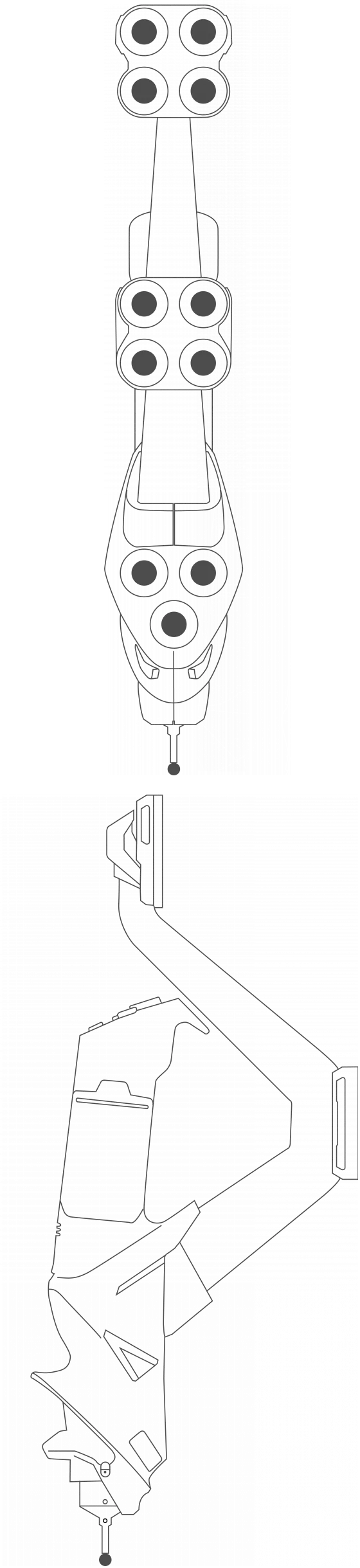

Creaform HandyPROBE

A Coordinate Measuring Machine Designed for the Shop Floor

Bring Quality Control to the Production Floor

The HandyPROBE portable coordinate measuring machine was designed to take reliable measurements on the shop-floor. Thanks to its dynamic referencing capability the HandyPROBE delivers metrology grade accuracy regardless of setup quality or experience level.

Accurate

The HandyPROBE delivers accurate, high resolution results - regardless of the environment.

Simple

Advanced optical and laser technologies allow for a point and shoot user experience. Real-time visuals can be viewed onscreen to guide your process and ensure a complete scan.

Fast

The typical object can be scanned in less than 5 minutes. Scans capture a robust amount of data, and produce ready to use files immediately. These files can be imported into CAD without post processing.

Handyprobe Features

Portable

Take the HandyPROBE anywhere, the system, tripod and accessories fit into a single carrying case. On location, the arm-free system offers the ultimate freedom of movement and versatility to measure parts of any size or geometry.

Metrology-grade Accuracy

Achieve accuracy of 0.025mm with a traceable certificate, on parts from .7-20 ft in size (.2-6m.) Optical reflectors perform dynamic referencing to ensure accuracy is reliable and consistent, no matter the environment.

Fast Setup, Easy to Use

The HandyPROBE's user-friendly design doesn't require any rigid setup, and instead can be moved freely in large spaces. It's optical reflectors make alignments automatic, eliminating the need for realignment when performing repetitive measurements.

SPECIFICATIONS

| Accuracy |

HandyPROBE Next™: 0.030mm (.0012 in) HandyPROBE Next™ | Elite: 0.025mm (.0009 in) |

|||||||||

| Volumetric Accuracy |

9.1m3 (320 ft3) HandyPROBE Next™: 0.086mm (.0034 in) HandyPROBE Next™ | Elite: 0.064mm (.0025 in) 16.6m3 (586 ft3) HandyPROBE Next™: 0.122mm (.0048 in) HandyPROBE Next™ | Elite: 0.078mm (.0031 in) |

|||||||||

| Volumetric accuracy with MaxSHOT 3D |

MaxSHOT Next™ HandyPROBE Next™: 0.060mm + 0.025mm/m (.0024 in + .0003in/ft) HandyPROBE Next™ | Elite: 0.044mm + 0.025mm/m (.0017 in + .0003in/ft) MaxSHOT Next™ | Elite HandyPROBE Next™: 0.060mm + 0.015mm/m (.0024 in + .00018 in/ft) HandyPROBE Next™ | Elite: 0.044mm + 0.015mm/m (.0017 in + .00018 in/ft) |

|||||||||

| Measurement rate | 80 measurements/s | |||||||||

| Part size range (recommended) |

0.2-6 m (0.7-20 ft) | |||||||||

| Software | VXelements |

|||||||||

| Weight |

Probe: 0.5 kg (1.1 lbs) C-Track: 5.7 kg (12.5 lbs) |

|||||||||

|

Dimensions (LxWxH) |

Probe: 68 x 157 x 340 mm (2.7 x 6.2 x 13.4 in) C-Track: 1031 x 181 x 148 mm (40.6 x 7.1 x 5.8 in) |

|||||||||

| Operating temperature range |

5-40°C | (41-104°F) | |||||||||

| Operating humidity range (non-condensing) | 10-90% | |||||||||

| Patents | FR 2, 838, 198, EP (FR, UK, DE, IT) 1, 492, 995 |

|||||||||

| Certifications |

EC Compliance (Electromagnetic Compatibility Directive, Low Voltage Directive), compatible with rechargeable batteries (when applicable), IP50, WEEE

(1) HandyPROBE Next and HandyPROBE Next|Elite performance assessment (ISO 17025 accredited) is based on partial procedure per ISO 10360-12 standard: Probing size error (6.2) and Length error (6.4). Performance is assessed on traceable sphere and length artefacts. (2) The volumetric accuracy of the system when using a MaxSHOT 3D cannot be superior to the default accuracy for a given model. |

|||||||||

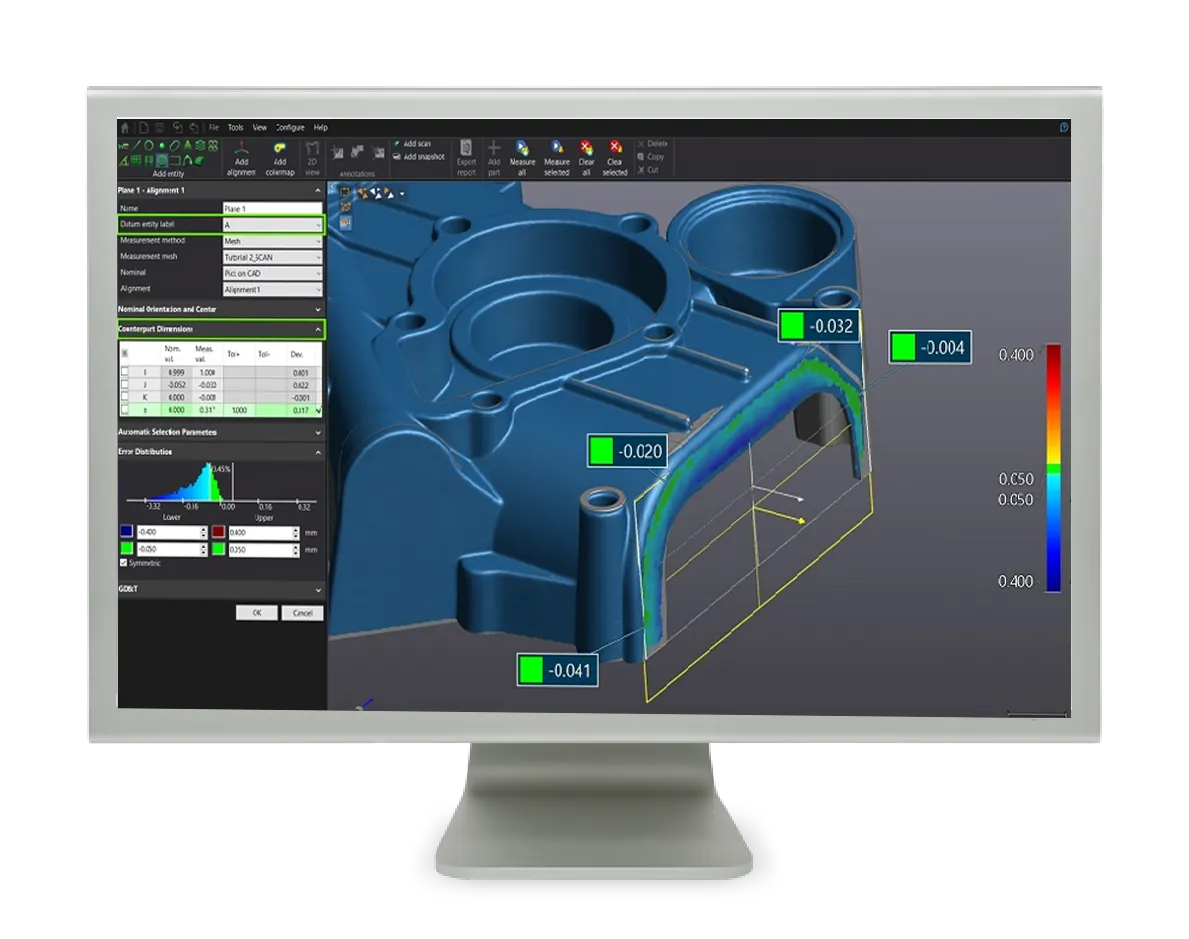

Software

No matter your application, GoEngineer has a specific 3D scanning software to fit your needs.

VXELEMENTS

3D SCANNING SOFTWARE PLATFORM

Creaform’s VXelements provides a fully integrated 3D software platform that powers the entire fleet of 3D scanning and measurement technologies. It gathers all the essential elements (VXscan, VXprobe, VXshot) and tools into a user-friendly, simple and sleek working environment.

ADDITIONAL Software

REVERSE ENGINEERING

Creaform VXModel

GeoMagic Design X

GeoMagic for SOLIDWORKS

GeoMagic Wrap

INSPECTION

Frequently Asked Questions

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services