Creaform HandySCAN

High Resolution Portable 3D Scanning

What is Creaform’s HandySCAN 3D laser Scanner?

The HandySCAN 3D™ laser scanner is a handheld 3D scanner ideal for scanning parts ranging from the size of a golf ball to the size of a small car. It is a great tool for both reverse engineering (scan-to-CAD) and inspection workflows. The HandySCAN is as close to “plug and play” as it gets in the 3D scanning world. It has proven to be an industry leader, award winner, and go-to option for professional 3D scanner users. It is one of the fastest, most accurate, portable, and easy to use 3D scanners on the market.

-

HandySCAN 3D BLACK

- Accuracy:

0.025 mm (0.0009 in) - Light Source:

7 blue laser crosses -

-

HandySCAN 3D BLACK ELITE

- Accuracy:

0.025 mm (0.0009 in) - Light Source:

11 blue laser crosses (+ 1 extra line) -

-

HandySCAN 3D BLACK ELITE limited

- Accuracy:

0.012 mm (0.0005 in) - Light Source:

11 blue laser crosses (+ 1 extra line) -

-

HandySCAN 3D SILVER

- Accuracy:

0.040 mm (0.0016 in) - Light Source:

14 blue laser crosses -

-

HandySCAN 3D silver elite

- Accuracy:

0.030 mm (0.0012 in) - Light Source:

14 blue laser lines (+ 1 extra line) -

-

HandySCAN 3D Max

- Accuracy:

0.150 mm (0.0059 in) - Light Source:

38 blue laser crosses -

-

HandySCAN 3D Max elite

- Accuracy:

0.075 mm (0.0030 in) - Light Source:

38 blue laser crosses -

HandySCAN Features

Portable

The HandySCAN comes in a robust hard case with everything needed to complete an amazing 3D scan. With its compact, briefcase like size, the HandySCAN is easy to travel with and can be packed into any vehicle or carried on to any commercial aircraft and fit into the overhead bins. The HandySCAN itself weighs about 2 lbs and has no hard-mounting connections. It is a handheld 3D scanner tethered only by a USB cable and a power connection. The USB cables come standard at 4 meters, can be ordered up to 16 meters, and power can be connected to a battery pack making the HandySCAN on of the most portable 3D scanners in the industry today.

Easy To Use

The HandySCAN can very quickly be plugged in, set up, and ready to begin scanning. The Creaform VXelements scanning software, which is included with the HandySCAN 3D scanner to complete the 3D scan process, is easy to learn, easy to follow, and easy to use. It even includes a guided workflow for beginners or more specialized 3D scanning projects. Even inexperienced users can complete great 3D scans with the HandySCAN.

HIGHEST ACCURACY

The HandySCAN is capable of holding 0.0005" accuracy and picking up extremely small details in a scan. The HandySCAN is often the go-to tool for shop floor inspections due to its speed, accuracy, and precision when 3D scanning virtually any surface including polished surfaces like gloss black and chrome. The HandySCAN is often able to replace the use of a slow CMM for inspection needs - and for reverse engineering, it's hard to beat the HandySCAN's scan quality and detail definition on parts.

ADD-ON ACCESSORIES

Max Shot 3D Photogrammetry and VXremote tablet. Creaform’s Max Shot 3D System can be integrated for product development, manufacturing, quality control and inspection teams that need the highest measurement accuracy and repeatability as much for large‑scale projects than for parts from 2 to 10 m. achieving an accuracy of 0.015mm/m or better. The VXremote tablet mirrors the screen on the computer the HandySCAN is connected to so the user can get into confined scanning areas and hard to reach places without having to try to keep the computer screen in view to see the scan data being collected.

SPECIFICATIONS

| FEATURES |

HandySCAN BLACK™ |

HandySCAN BLACK™ | Elite & Limited |

HANDYSCAN SILVER™ & SILVER ELITE |

HandySCAN 3D MAX & max elite |

| Accuracy (1) | (0.0014 in) |

(0.0009 in) |

0.040 mm

|

0.150 mm (0.0059 in) 0.075 mm (0.0030 in) |

| Volumetric accuracy (2) (based on part size) |

(0.0008 in + 0.0007 in/ft) |

(0.0008 in + 0.0005 in/ft) with Limited Edition (4) |

0.020 mm + 0.100 mm/m (0.0008 in + 0.0012 in/ft) 0.020 mm + 0.060 mm/m (0.0008 in + 0.0007 in/ft) |

0.200 mm + 0.030 mm/m |

| Volumetric accuracy with MaxSHOT Next™ | Elite (3) | (0.0008 in + 0.00018 in/ft) |

|||

| Measurement resolution | (0.0009 in) |

0.030 mm (0.0012 in) | 0.04 mm (0.0016 in) |

|

| Mesh resolution | (0.0039 in) |

0.200 mm (0.0079 in) | 0.4 mm (0.0157 in) |

|

| Measurement rate | 800,000 measurements/s | 2,250,000 measurements/s | ||

| Light source | (+ 1 extra line) |

14 blue laser lines 14 blue laser lines (+ 1 extra line) |

38 blue laser lines | |

| Laser class | (eye-safe) |

|||

| Scanning area | (12.2 x 13.8 in) |

1 x 1 m (3.3 x 3.3 ft) |

||

| Stand-Off Distance | (11.8 in.) |

0.45 to 1.60 m (1.5 to 5.2 ft) |

||

| Depth-of-field | 250 mm (9.8 in) | 1.15 m (3.8 ft) 2.20 m (7.2 ft) |

||

| Part size range (recommended) | (0.15–13 ft) |

0.05-4 m (0.15-13.1 ft) |

1–10 m (3.3–32.8 ft) 1–15 m (3.3–49.2 ft) |

|

| Software | ||||

| Output Formats | .dae, .fbx, .ma, .obj, .ply, .stl, .txt, .wrl, .x3d, .x3dz, .zpr, .3mf | .dae, .fbx, .ma, .obj, .stl, .txt, .wrl, .x3d, .zpr, .3mf | .dae, .fbx, .ma, .obj, .ply, .stl, .txt, .wrl, .x3d, .x3dz, .zpr, .3mf | |

| Compatible Software |

|

|

||

| Weight | (2.1 lb) |

1.22 kg (2.7 lb) |

||

| Dimensions (LxWxH) |

(5.6 x 3.1 x 11.3 in) |

133 x 79 x 435 mm (5.2 x 3.10 x 17.10 in) |

||

| Connection standard | ||||

| Operating temperature range | (41-104 °F) |

|||

| Operating humidity range (non-condensing) |

||||

| Certifications | ||||

| Patents |

CA 2,600,926, US 7,912,673, CA 2,656,163, EP (FR, UK, DE) 1,877,726, AU 2006222458, US 8,032,327, JP 4,871,352, US 8,140,295, EP (FR, UK, DE) 2,278,271, EP (FR, UK, DE) 2,230,482, IN 266,573, US 7,487,063, CA 2,529,044, EP (FR, UK, DE) 3,102,908, US 10,271,039, JP 6,596,433, CA 2,938,104, KR 10-2424135 Max Elite also includes: US 7,487,063, CA 2,529,044 |

|||

(1) HandySCAN BLACK and HandySCAN BLACK Ι Elite (ISO 17025 accredited): Based on VDI/VDE 2634 part 3 standard. Probing error performance is assessed with diameter measurements on traceable sphere artefacts (ISO 17025 accredited). HandySCAN 307: Typical value for diameter measurement on a calibrated sphere artefact.

(2) HandySCAN BLACK and HandySCAN BLACK Ι Elite (ISO 17025 accredited): Based on VDI/VDE 2634 part 3 standard. Sphere-spacing error is assessed with traceable length artefacts by measuring these at different locations and orientations within the working volume. HandySCAN 307: Value for spheres spacing measurement on a calibrated length artefact.

(3) The volumetric accuracy of the system when using a MaxSHOT 3D cannot be superior to the default volumetric accuracy of the chosen system and model.

(4) Limited Edition is able to deliver improved accuracy through optimized manufacturing and calibration processes.

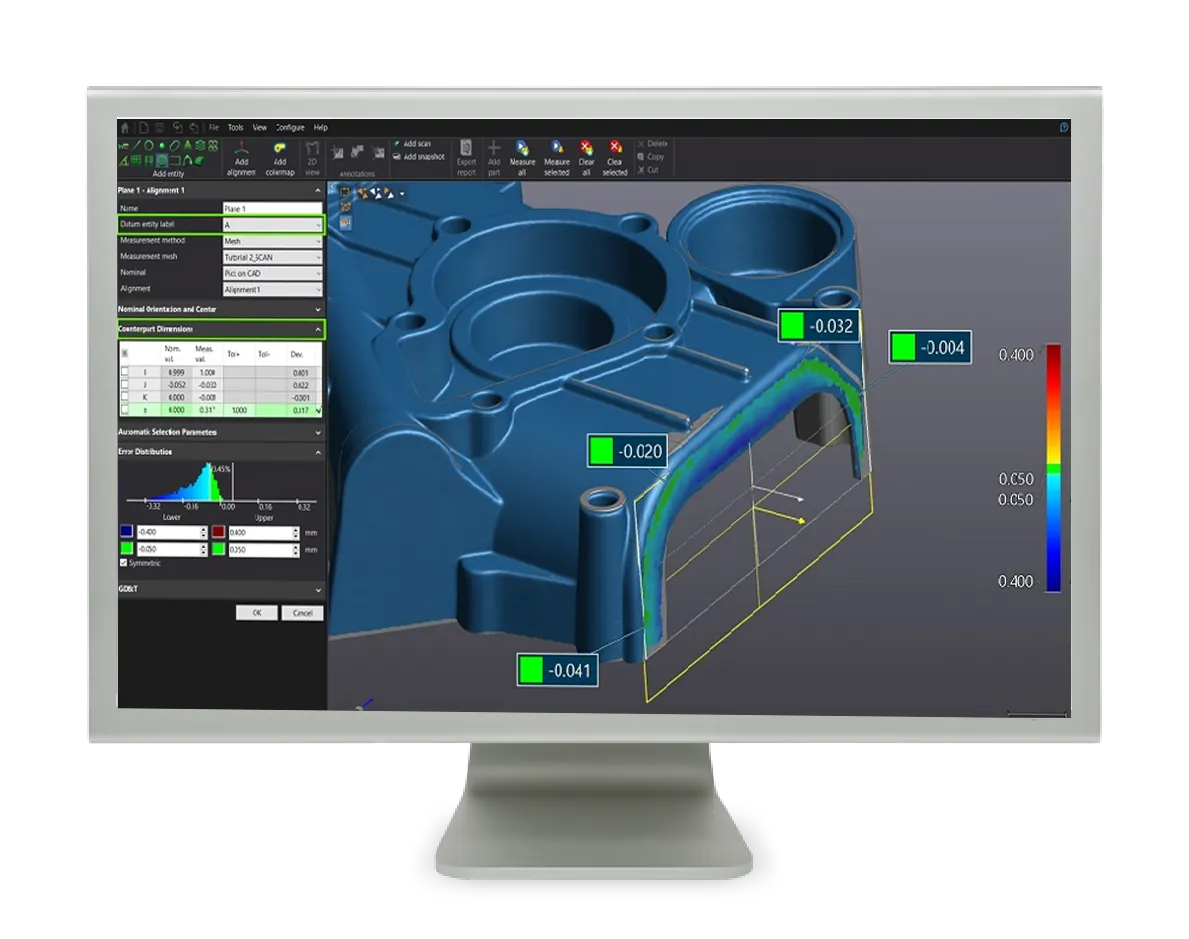

Software

No matter your application, GoEngineer has a specific 3D scanning software to fit your needs.

VXELEMENTS

3D SCANNING SOFTWARE PLATFORM

Creaform’s VXelements provides a fully integrated 3D software platform that powers the entire fleet of 3D scanning and measurement technologies. It gathers all the essential elements (VXscan, VXprobe, VXshot) and tools into a user-friendly, simple, and sleek working environment.

ADDITIONAL Software

REVERSE ENGINEERING

Creaform VXModel

GeoMagic Design X

GeoMagic for SOLIDWORKS

GeoMagic Wrap

INSPECTION

Frequently Asked Questions

No, the native 3D scan files are typically .STL or .OBJ we recommend using 3D scanning software made to work with these types of files as a bridge software to go from 3D scan to CAD. Check out our list of recommended software.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services