SOLIDWORKS MBD

Define, Organize, and Publish 3D Product Manufacturing Information (PMI)

What is SOLIDWORKS MBD?

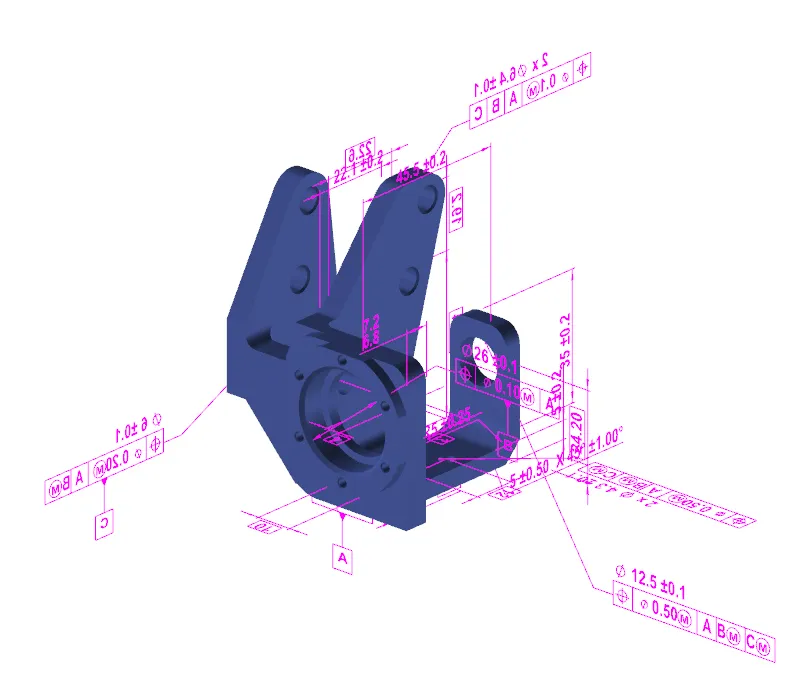

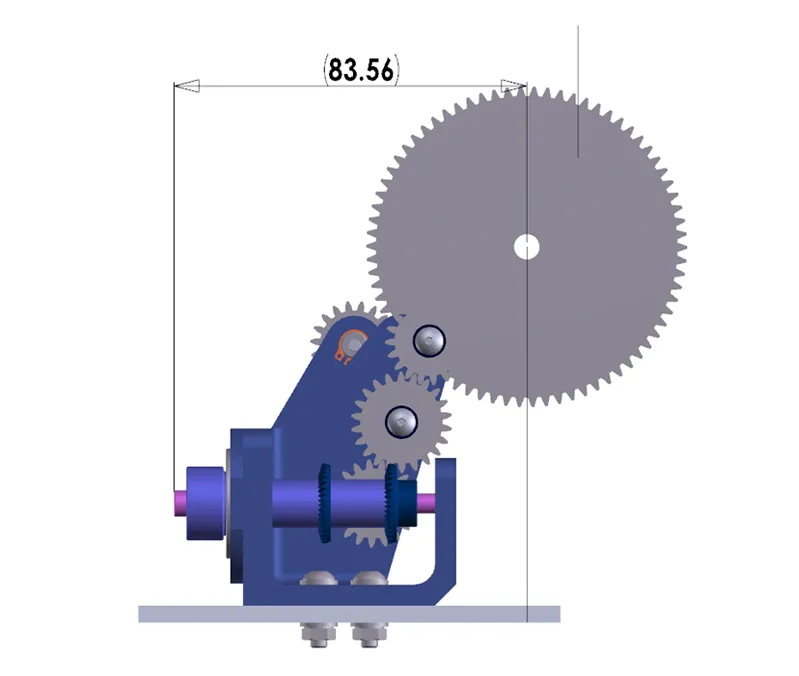

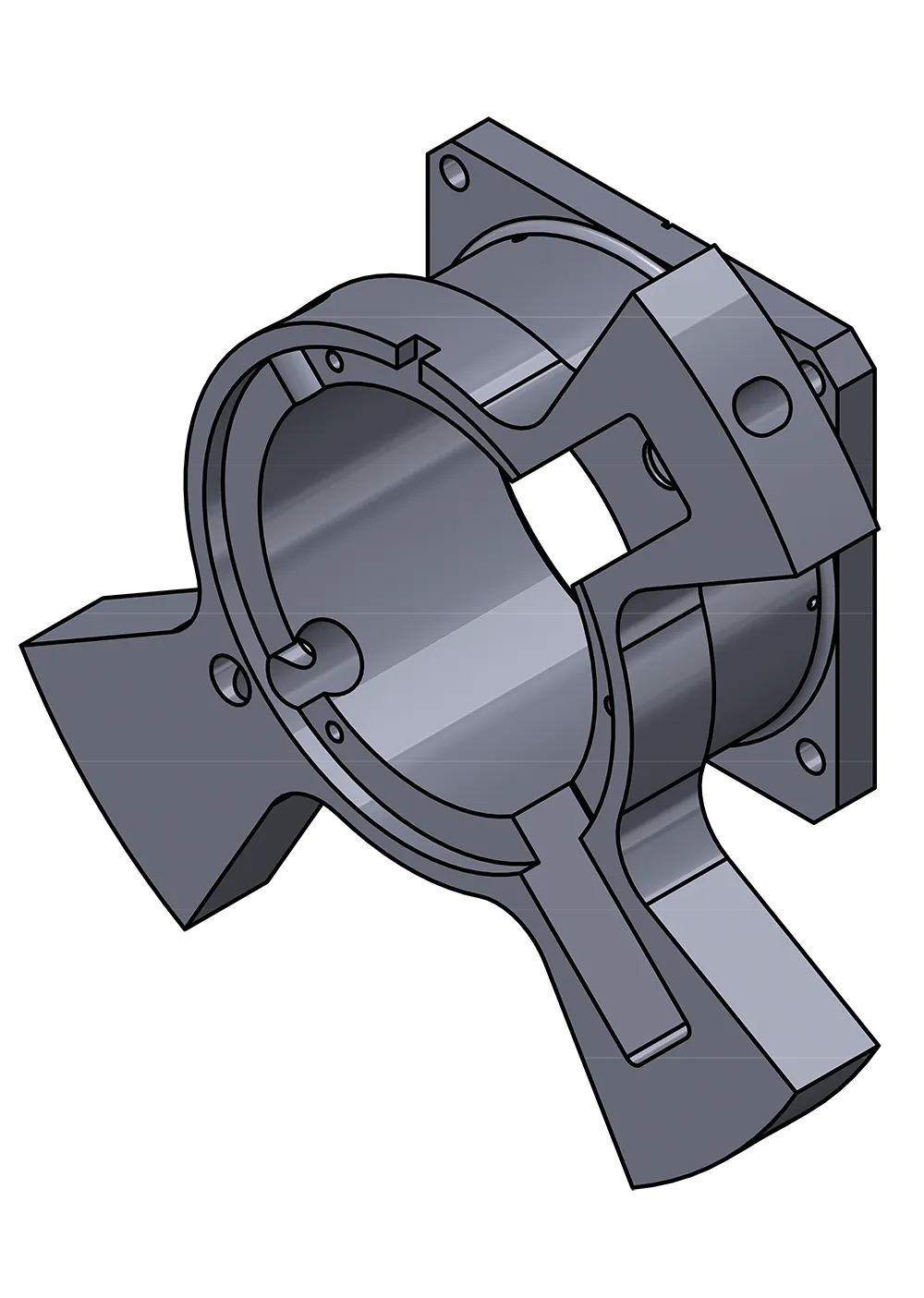

SOLIDWORKS MBD (Model Based Definition) is an integrated drawingless manufacturing solution for SOLIDWORKS that helps define, organize, and publish 3D Product Manufacturing Information (PMI) including 3D model data in industry-standard file formats.

SOLIDWORKS MBD guides the manufacturing process directly in 3D instead of using traditional 2D drawings, which helps streamline production, cut cycle time, reduce errors, and support industry standards.

SOLIDWORKS MBD PDF Examples:

(To view 3D content pdf's, be sure your firewall and pop-blocker is disabled. Recommend Adobe Acrobat for best viewing experience.)

Tools

SOLIDWORKS MBD

Advanced tools to help expedite first article and in-process inspection reports.

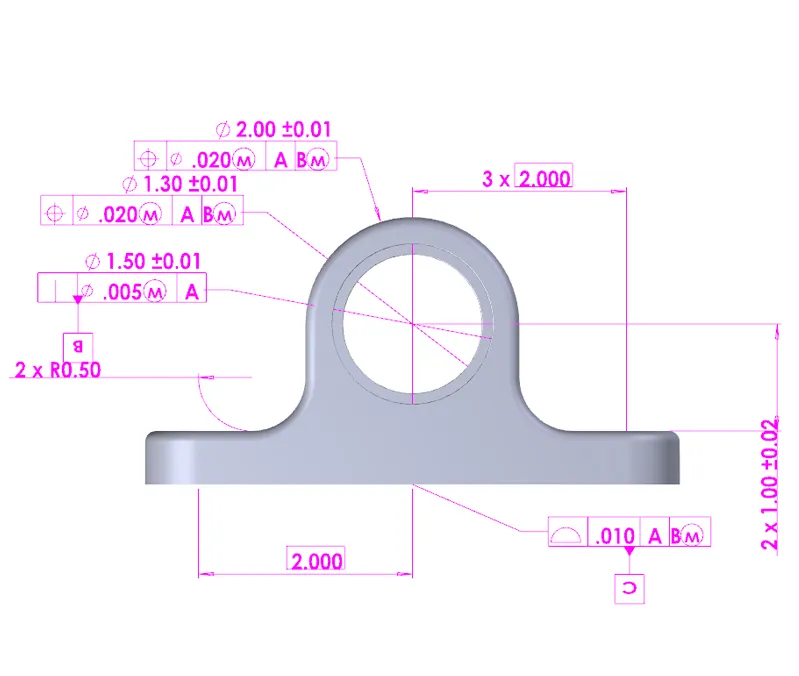

Define 3d PMI

Define 3D Product Manufacturing Information (PMI) such as dimensions, tolerances, model data, surface finish, weld symbols, Bill of Materials (BOM), tables, notes, and other annotations.

PUBLISH 3d PDF DRAWINGS

Publish 3D data and PMI in industry-standard file formats, such as 3D PDF and eDrawings.

Organize 3d PMI

Organize 3D PMI along with the 3D models in a clean, structured, and easy-to-search fashion.

SUPPORTED INDUSTRY STANDARDS

Support industry standards, such as Military-Standard-31000A, ASME Y14.41, ISO 16792, and DIN ISO 16792.

CustomizeD Output Templates

Customize 3D output templates for multiple deliverables [such as engineering drawings and request for quote (RFQ)], and departments [such as Operations, Manufacturing, QA, and Procurement].

SHARED 3D DATA

Share and archive 3D data to minimize time spent re-modeling or manipulating 2D drawings.

SOLIDWORKS MBD Features

CREATE 3D PMI SEAMLESSLY

See how SOLIDWORKS MBD can be used to quickly create accurate 3D Product Manufacturing Information that can replace or supplement typical 2D Manufacturing Drawings.

SHARE YOUR FILES

Learn how to use SOLIDWORKS MBD to add 3D PMI to standard file formats (eDrawings, 3D PDF, Step), to easily share Product Manufacturing Information throughout your organization and supply network.

COMPARE SOLIDWORKS MBD

|

|

SOLIDWORKS MBD |

TRADITIONAL

SOLIDWORKS |

3D PRODUCT MANUFACTURING INFORMATION (PMI) DEFINITION |

||

| Intelligent Dimensioning, Tolerancing, and Annotation (DimXpert) Freestyle Dimensioning, Tolerancing, and Annotation (Reference Dimensions) Comprehensive Bill of Materials (BOM) |

|

|

3D PMI ORGANIZATION |

|

|

| 3D Annotation Views |

|

|

| Automatic Show and Hide Annotations as a Model Rotates |

|

|

| 3D Views capturing Annotation Views, Configurations, Display States, Section View, and other View Settings |

|

|

| 3D Model Break Views |

|

|

| 3D Radial Explode Views |

|

3D OUTPUT |

|

|

| Publish to eDrawings |

|

|

| 3D Output Template Customization |

|

|

| Rich Predefined 3D Output Templates |

|

|

| 3D PDF with 3D PMI, Views, and Meta Properties |

|

|

SOLIDWORKS Services:

Utilize GoEngineer’s Award Winning Support & Training for SOLIDWORKS

Award Winning Technical Support

GoEngineer's extensive SOLIDWORKS technical knowledge and world class support can help you succeed with SOLIDWORKS. Our award-winning team is ready to help you with any task you may have. Using state-of-art remote assistant technology software allows our team to solve most issues within one session. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

- 125+Certified Technical Specialists

- Email, Phone and Chat Support Available

- 98% Exceptional Customer Service Rating

PROFESSIONAL SOLIDWORKS TRAINING

GoEngineer offers online and classroom professional SOLIDWORKS training for organizations and individuals. All our instructors are SOLIDWORKS certified and teach thousands of students each year world wide. The curriculum is very diverse with numerous certified SOLIDWORKS courses to choose from. Each student will receive a Course Completion Certificate and preparation materials for SOLIDWORKS certification.

- Increase Your Earning Potential

- Led by Certified SOLIDWORKS Instructors

- Smaller Classes with Focused Attention

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

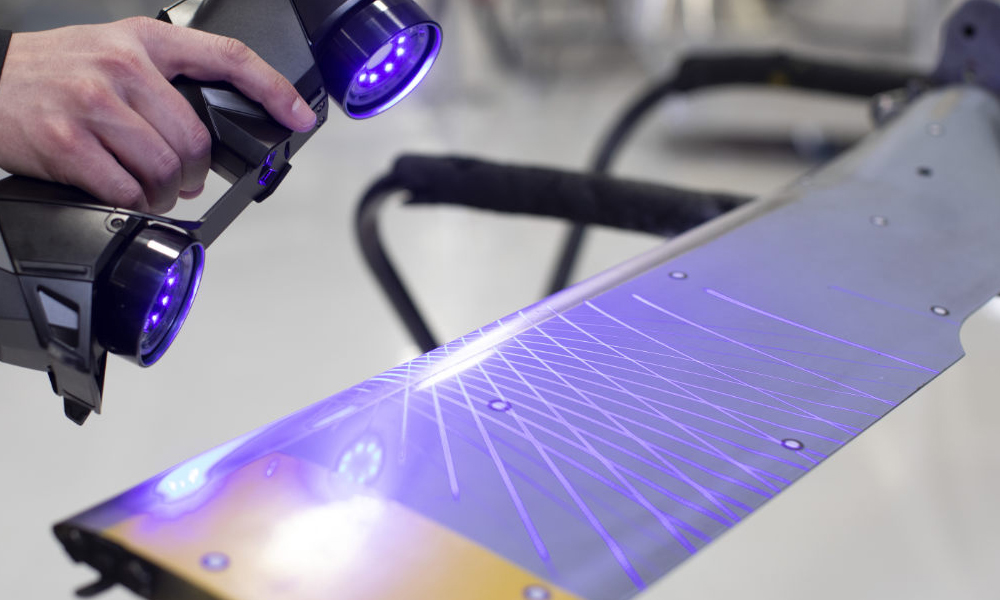

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet, SL, or Metal 3D printers. 3D Printing Services