Processor:

3.3GHz or faster, Intel® Core i5, i7 or equivalent AMD®

Operating System:

Windows® 10 or 7 x64

Memory:

8GB or more recommended

Hard Drive:

Standard or Solid State Drive (SSD) > 250GB, keeping 10% drive capacity free space

Graphics Cards:

NVIDIA® Quadro®

P600, P1000 series

- System for simple parts, small assemblies (200 or fewer components), and drawings.

- This system will support part and assembly simulations including linear statics, thermal, frequency, fatigue, and optimization. Gap and contact simulations will run on small assemblies that contain simple components.

- This system will also support simple flow simulations.

- Approximate Costs: Laptop – $1600 | Desktop – $1400

Basic System

Processor:

3.3GHz or faster, Intel® Core i7, Xeon or equivalent AMD®

Operating System

: Windows® 10 or 7 x64

Memory

:

8-16GB or more as required

Hard Drive:

Solid State Drive (SSD) > 250GB, keeping 10% drive capacity free space

Graphics Cards:

NVIDIA® Quadro®

P2000 series

- System for complex parts with advanced shapes, large patterns, shells, 200+ features.

- This system is also for assemblies containing 200-1000 components and drawings.

- This system will support part and assembly simulations including non-linear, dynamics, random vibrations along with moderate gaps and contacts.

- This system will also support moderate flow simulations.

- Approximate Costs: Laptop – $2100 | Desktop – $1800

Advanced System

Processor:

3.3GHz or faster, Intel® Core i7, Xeon or equivalent AMD®

Operating System

: Windows® 10 or 7 x64

Memory:

16-32GB or more as required

Hard Drive:

Solid State Drive (SSD) > 250GB, keeping 10% drive capacity free space

Graphics Cards:

NVIDIA® Quadro®

P3000 P4000 series

- System for very complex parts with advanced surfacing features or hybrid modeling.

- This system is also for assemblies containing 1000 – 200,000 components.

- This system will support large complex analysis and large flow simulations.

- Approximate Costs: Laptop – $3000 | Desktop – $2500

Minimum hardware requirements for SOLIDWORKS 2019:

The minimum requirements can be found on the SOLIDWORKS System Requirements website .

Video:

A certified OpenGL workstation graphics card and driver.

For a listing of tested and certified graphics cards and driver, combinations visit the SOLIDWORKS System/Graphics Card Requirements Website.

http://www.solidworks.com/sw/support/videocardtesting.html

CPU:

Intel® or AMD® with SSE2 support. A 64-bit operating system required.

SOLIDWORKS is supported on Apple Mac® based machines running under Parallels.

http://www.solidworks.com/sw/support/11168_ENU_HTML.htm

NOTE:

Non-server products are only supported in the Parallels environment.

eDrawings® is supported on Apple Macintosh®-based machines.

Other:

Mouse or another pointing device.

DVD drive or broadband internet connection

Microsoft Excel 2010, 2013, or 2016

Internet Explorer version 8 or higher

Anti-Virus (

http://www.solidworks.com/sw/support/AntiVirus_SW.html

)

Network:

SOLIDWORKS is tested only with Microsoft’s Windows Networking and Active Directory network environments.

Novell networks and non-Windows based network storage devices are not supported.

OS:

Window 10® (SOLIDWORKS 2015 SP5+)

Note

: Windows Home, Small Business, and To Go editions are not supported.

Windows 7® 64-bit professional or greater editions only

SNL Server Requirements:

Windows 7®, 10®

Windows Server 2012® R2, 2016®

Virtual servers are supported for SNL only for the ones listed here (

http://www.solidworks.com/sw/support/11168_ENU_HTML.htm

).

PDM Professional, Standard:

The system requirements for PDM can be found here, http://www.solidworks.com/sw/support/PDMSystemRequirements.html

End of Life Product Info

http://www.solidworks.com/sw/support/solidworks-support.htm?tabshow=2

System Samples

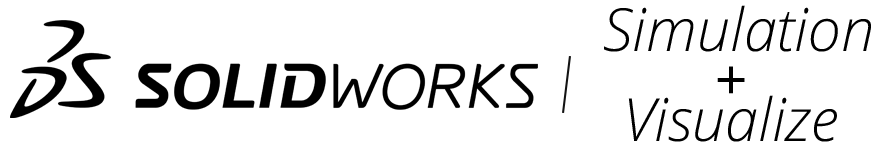

Minimum System from Dell®

Figure 1 – Minimum System Sample from Dell®

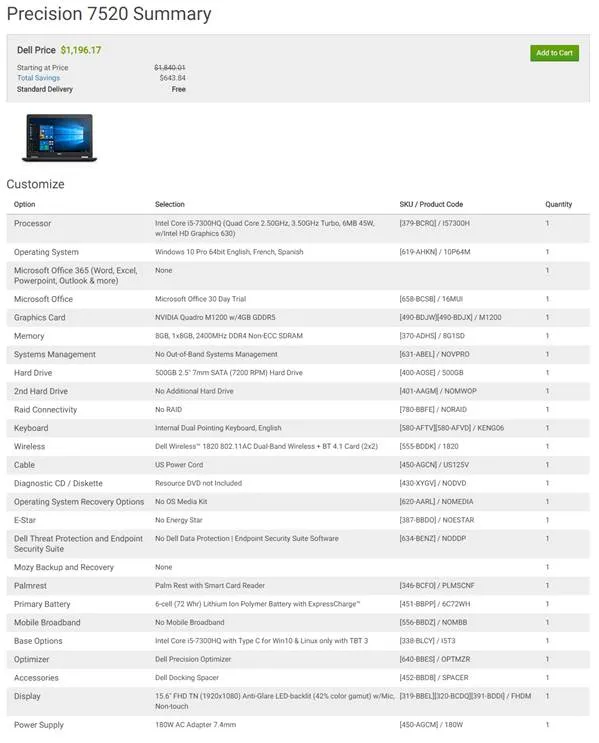

Basic System from Dell®

Figure 2 – Basic System Sample from Dell®

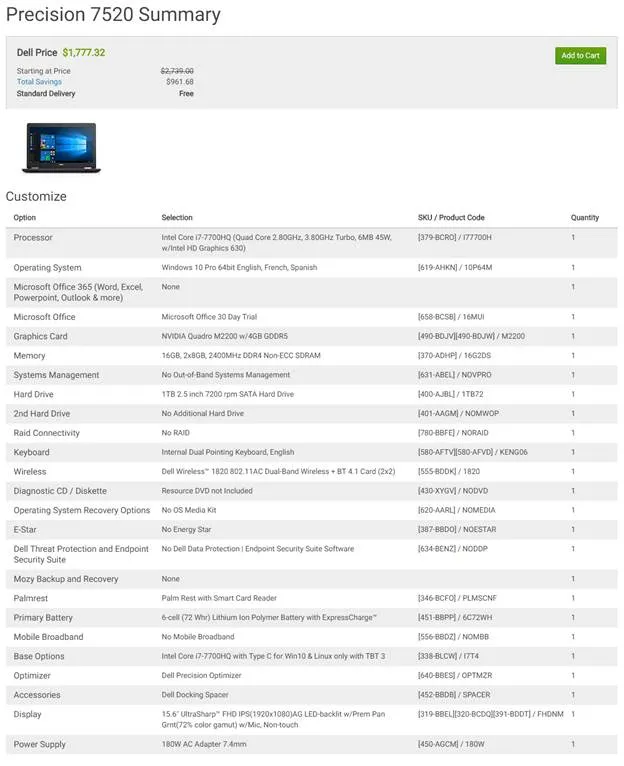

Advanced System from Dell®

Figure 3 – Advanced System Sample from Dell®