-

$0.00

Parts Total

-

Shipping

Calculated at checkout -

$0.00

Subtotal

Sales Tax Excluded -

Lead Time Estimate: Typically within 3 business days.

Orders received after 2PM CST will be processed next day.

3D PRINTING SERVICES

Order custom 3D Printed Prototypes and Parts

New

GoEngineer Instant 3D Printing Service Quote Tool –

Now in Beta!

Our new instant quoting tool below for 3D printing services is currently in beta testing. If you have any questions or encounter any issues, please feel free to

Contact Us.

Thank you for your support and patience as we work to improve your experience.

Custom Online 3D Printing Service

Get Professionally 3D Printed Prototypes and Production Parts with GoEngineer's High Quality 3D Printing Services.

![]() ITAR Registered

ITAR Registered

![]() ISO 9001:2015 Certified

ISO 9001:2015 Certified

![]() AS9100 Certified

AS9100 Certified

Available Technologies

FDM | PolyJet | Stereolithography | SAF | P3

Why Choose GoEngineer?

High Quality 3D Printing Services

Get Commercial Quality Rapid Prototyping and Production Parts From Additive Manufacturing Industry Experts

GoEngineer sets the standard for cutting-edge high quality 3D printing services tailored to meet the demands of professional and commercial sectors.

With a specialty in aerospace and defense applications, our team is ready to handle the most demanding regulations.

Whether you're in need of precision prototypes or production-grade components and materials, we provide on-demand solutions and

technical support

ensuring your projects stay ahead of the curve.

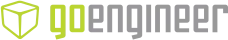

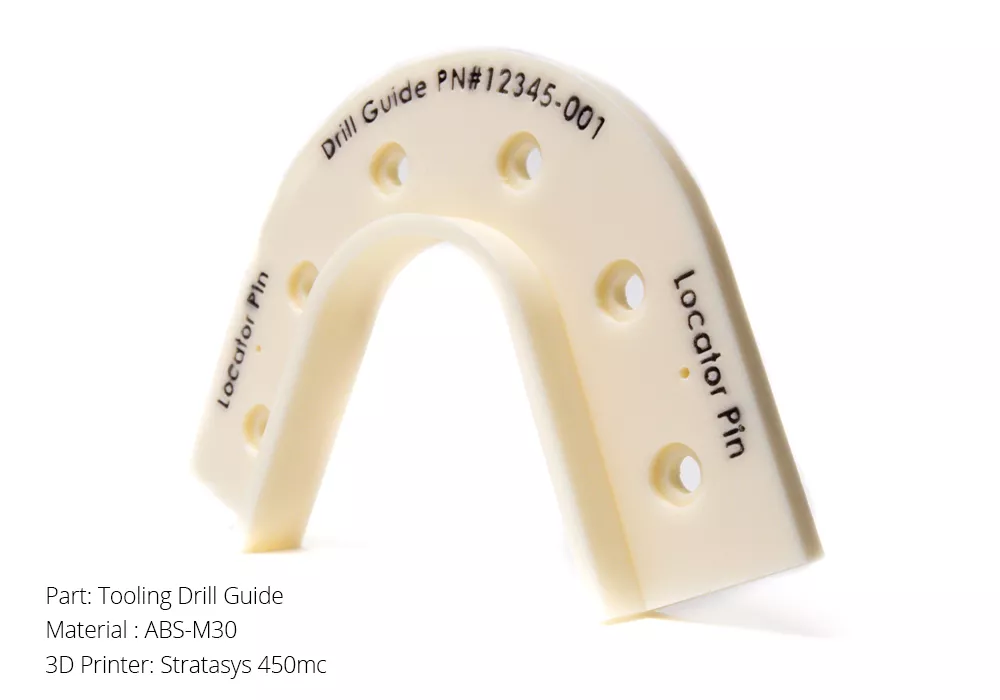

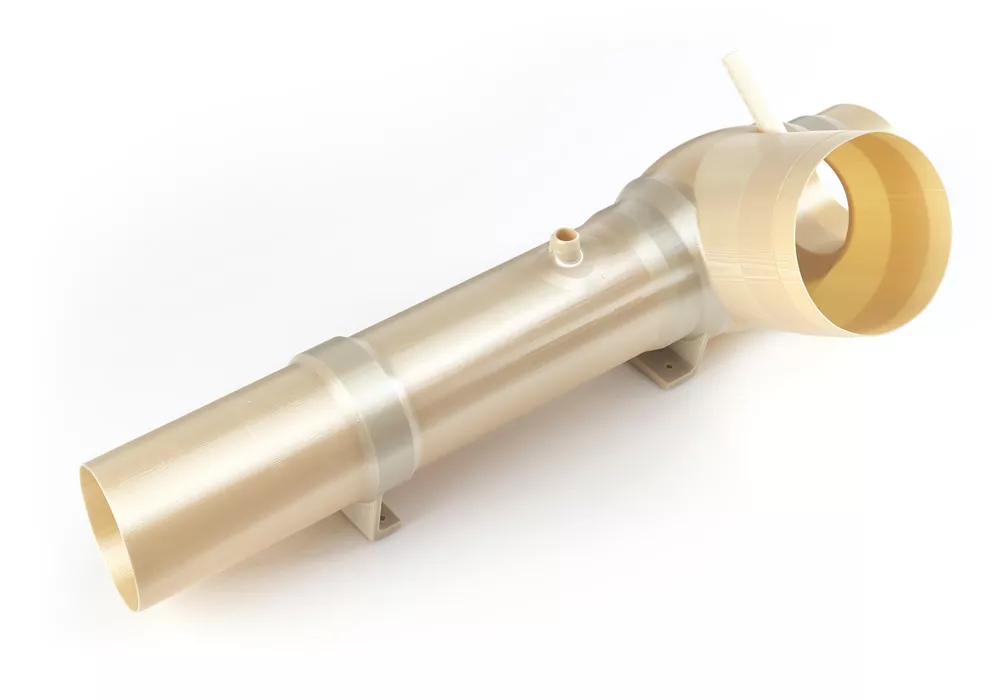

Our state-of-the-art equipment features commercial and industrial-grade 3D printers for a variety of technologies, including the Stratasys F900, Neo 800, J850 Pro, and more. With GoEngineer, you gain access to the forefront of additive manufacturing, ensuring your projects in aerospace and defense benefit from precision, reliability, and innovation.

As your trusted partner, GoEngineer serves as the go-to destination for high-precision, custom 3D printed parts designed for professional and commercial use. Upload your CAD file(s) to receive a custom quote and lead time — streamlining the process for your convenience.

trusted

by industry leaders

trusted

by industry leaders

How Much Do 3D Printing Services Cost?

In general, 3D printing service costs can be influenced by the following factors:

It's important to consider these factors and communicate your specific requirements with any 3D printing service provider to get an accurate estimate of all costs involved. Additionally, prices in the 3D printing industry can evolve, so checking with the your service provider for the most current information is always a good practice.

Learn more about GoEngineer and their 40+ years of experience in the additive manufacturing industry.

Different 3D printing materials have varying costs. Common materials, such as PLA, ABS, PETG typically have a lower cost than more specialized options like flexible filaments or high-performance resins. View GoEngineer's extensive line of 3D Printing Materials.

Printing TechnologyThe methods used for 3D printing, such as Fused Deposition Modeling (FDM) , PolyJet , Stereolithography (SL) , Selective Absorption Fusion (SAF) , Programmable Photopolymerization (P3) , Selective Laser Sintering (SLS), or others, can impact the cost.

Print Size and ComplexityLarger prints generally require more material and time, contributing to higher costs. Intricate or complex designs may also increase costs due to the precision required during printing. The Stratasys F900 3D Printer can print an area of up to 36″ x 24″ x 36″.

Resolution and Layer HeightHigher resolution and finer layer heights often result in better print quality but may also increase printing time and material usage. For more information on how this can impact 3D printing costs, contact a 3D printing expert.

Post-Processing RequirementsIf post-processing steps such as sanding, painting, or additional finishing are necessary, they can add to the overall cost of 3D printing services.

QuantityGoEngineer's 3D printing service offers discounts for larger quantities of the same print; incentivizing bulk orders and providing cost savings for customers with extensive printing needs. There is a $200 minimum order required for custom print jobs.

What Industries Do you Serve?

High Quality 3D Printed Parts for All Industries

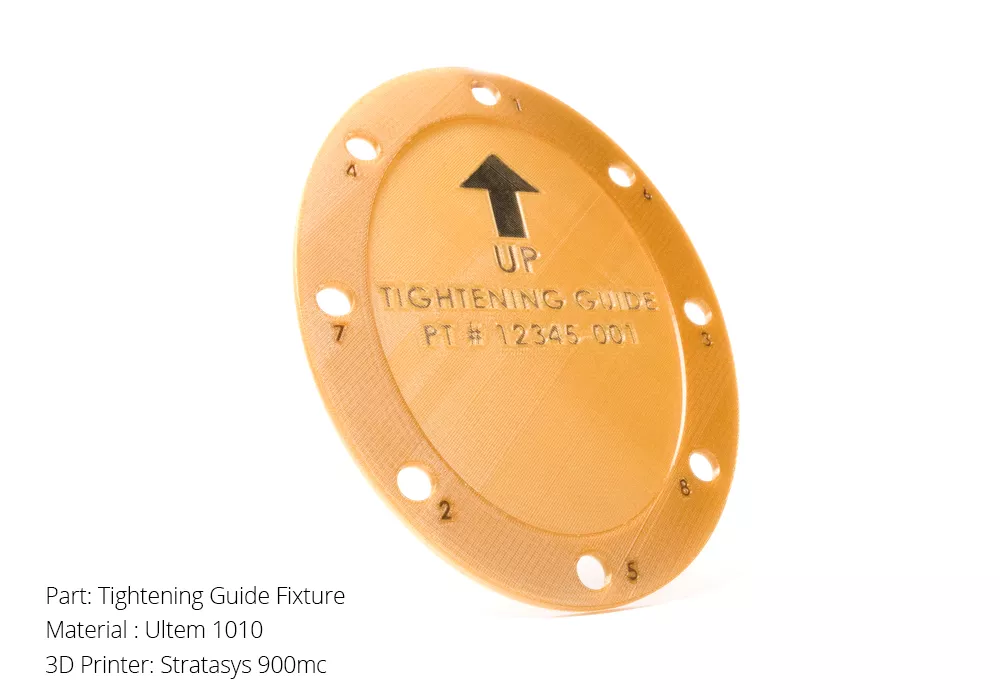

GoEngineer's 3D Printing Service has the additive manufacturing technology to serve every industry including defense, aerospace, automotive, start-ups, and many more!

AEROSPACE

GoEngineer's certified, ITAR compliant 3D Printing Services offers cutting-edge 3D printing technologies and a versatile array of materials. As a reliable partner in the aerospace sector, we empower clients to accelerate their product development cycles while maintaining the highest standards of quality and performance.

Automotive

GoEngineer accelerates automotive product development by producing intricate prototypes and production parts. The diverse range of 3D printers available cater to various scales and complexities, ensuring adaptability to automotive needs. Complemented by a comprehensive materials portfolio, featuring high-performance polymers and composites.

Defense

Our commercial line of Stratasys 3D printers enables rapid prototyping, design optimization, and efficient product development for defense applications. GoEngineer 3D Printing Services facilitates innovation and efficiency in the defense sector, keeping manufacturers at the forefront of engineering and production advancements.

...and more

GoEngineer's 3D Printing Services caters to a diverse range of industries, showcasing a commitment to innovation and technological excellence. From industries like medical and dental to fashion, film, and manufacturing, GoEngineer offers a versatile array of materials and cutting-edge printing technology to bring creative visions to reality for all types of engineers & designers.

If you need additional information on 3D printing technologies to fit your custom part needs please Contact GoEngineer

“These 3D printed models give us the best opportunity to re-create human physiologic conditions on a structural basis to simulate clinical situations and study new devices to establish their effectiveness before introducing them into patients.”

Additional FAQ's

3D Printing Services Quoting & Process Questions

3D Printing Services Available Equipment and Material Questions

- Wide array of material options including, high temp, high strength, fire retardant, and multiple colors

- Engineering-grade materials

- Large platform 36” x 24” x 36”

- Array of print resolutions .005, .007, .010, .013, .020

- Cost-effective and fast option for larger parts (T-40 ASA and Ultem 1010)

- Fast lead times

- Parts that need good detail and strength

- Fast and cost-effective on small parts

- Fast lead times

- Thin walls are printed well

- Ability to pack parts for cost reduction

- Fine detail/surface finish

- An array of materials including clear

- The best option for master patterns for cast urethane

- Investment casting applications

3D Printing Services Quality Questions

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services