About GoEngineer

Empowering the Creation of Today's Products and Tomorrow's Innovations

Get To Know GoEngineer

Collaboration and partnership with our customers is at the center of everything we do. With 40 years of experience and tens of thousands of customers in high-tech, medical, machine design, energy and other industries. Empowering the Creation of Today's Products and Tomorrow's Innovations. We are also pleased to support Educational communities as the National and Global leader for Colleges, Universities, and schools.

75,000+

SOLIDWORKS USERS

#1 rESELLER

FIVE YEARS IN A ROW

TRAINING

WORLD CLASS INSTRUCTION

OVER 220+

CERTIFIED TECH AGENTS

60 OFFICES

ACROSS THE U.S.

120K+

YOUTUBE SUBSCRIBERS

SUPPORT

Tech Support

With 125+ certified technical specialists, we’ll get you to the expert you need quickly. You can call our technical support team directly at 1-888-559-6167. For RP / Additive Manufacturing support, call 1-855-470-0647. Or send us an email at support@goengineer.com, RP / Additive Manufacturing Support: AMsupport@goengineer.com

Schedule a session and choose the product, topic and expert of your choice.

Intended Use: Fixing errors given by the software, investigating potential bugs in the software. Not meant for training needs.

Application Mentoring Session

Application Mentoring Sessions give you the opportunity to meet with one of our highly skilled Application Engineers. This allows you to explore the full scope of your technology investment in a personalized and focused setting. Discuss your needs, ask questions, or get demonstrations in any engineering area or SOLIDWORKS product.

Schedule a remote Application Mentoring Session with one of our experts.

Intended Use: Round table forums on learning more about how the software is used and applied to specific company needs.

TRUSTED PARTNERS

As the maker of SOLIDWORKS, CATIA, Abaqus, 3DEXPERIENCE, and more, Dassault Systèmes is a global leader in product development technology. Their solutions drive innovation with cutting-edge capabilities in design, simulation, manufacturing, and collaboration.

SOLIDWORKS® 3D CAD software delivers powerful design functionality with an intuitive user interface to speed up your design process.

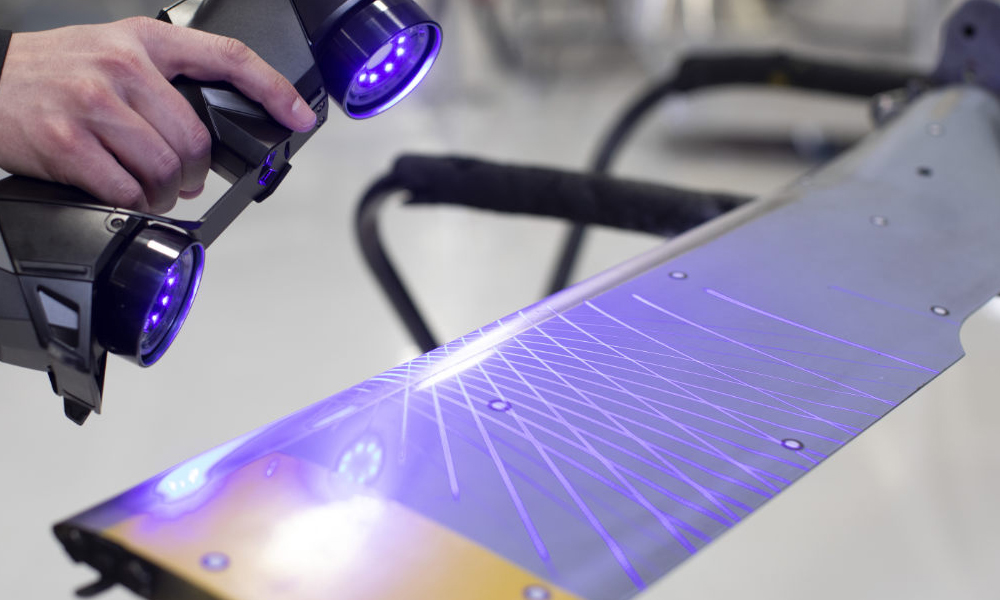

Together with Creaform, GoEngineer offers a variety of Portable 3D Scanning technologies that have been developed to meet the specific needs of a wide range of applications.

Artec`s handheld 3D scanners are professional solutions for 3D digitizing real-world objects with complex geometry and rich texture in high resolution.

![]()

VELO3D offers revolutionary support free metal 3D printing. The next generation metal laser powder bed fusion technology allows manufacturing companies to produce mission-critical parts.

Xact Metal's high-quality, small footprint 3D printers are accessible to companies ready to experience metal powder-bed fusion additive manufacturing at an affordable price.

Oryx offers an easy-to-use, cost-effective, and automated support removal system compatible with all water soluble materials, solvent-based support materials. and a variety of both FDM and PolyJet base modeling materials.

DyeMansion finishing solutions is the industry leading print-to-product workflow that makes 3D printed products a part of everyday life by providing surfaces that challenge injection molding.

peel 3d offers high-performance handheld 3D scanning at an affordable price. Perfect for applications in engineering, preservation, heathcare, and more.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet, SL, or Metal 3D printers. 3D Printing Services