Stratasys Truck Show

Explore the latest 3D printers, materials, and real-world parts — including the new F3300™ — with experts ready to answer your toughest engineering questions..Learn More >

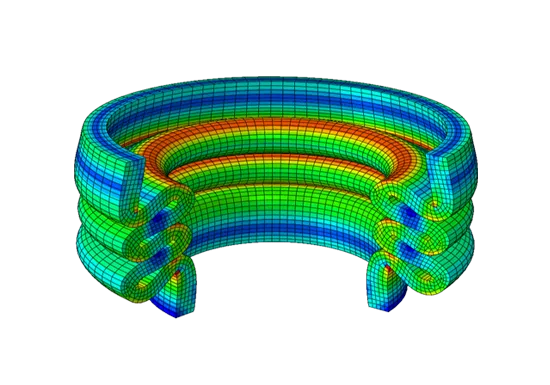

Abaqus Buying Guide

Navigate the buying process with confidence. This guide breaks down licensing options, pricing, and key features to help you choose the right Abaqus solution for your team.Learn More >

CAD Micro is GoEngineer!

On January 3, 2025, CAD Micro joined GoEngineer! Creating North America’s premier destination for product design innovation, outstanding support, and unmatched service.Learn More >

Formlabs Now Available!

GoEngineer now offers Formlabs 3D Printers! Discover high-quality, reliable solutions for every industry. Request a quote today and explore advanced 3D printing options.Learn More >

SEE WHAT'S NEW

Learn more about SOLIDWORKS 2025 and 3DEXPERIENCE SOLIDWORKS enhanced product features and upgrades.Learn More >

JOIN THE COMMUNITY

A forum created by engineers, for engineers. Join to access industry experts and connect with the engineering community.Learn More >

JOIN THE COMMUNITY

3D Printing Services

With over 100 machines across the US, including FDM, PolyJet, Stereolithography, P3, and SAF technologies, our team will take your project from idea to end part.Learn More >

SOLIDWORKS Discounts

Take advantage of exclusive discounts and promotions on industry-leading CAD tools to enhance your design and engineering projects. Don't miss out!Learn More >

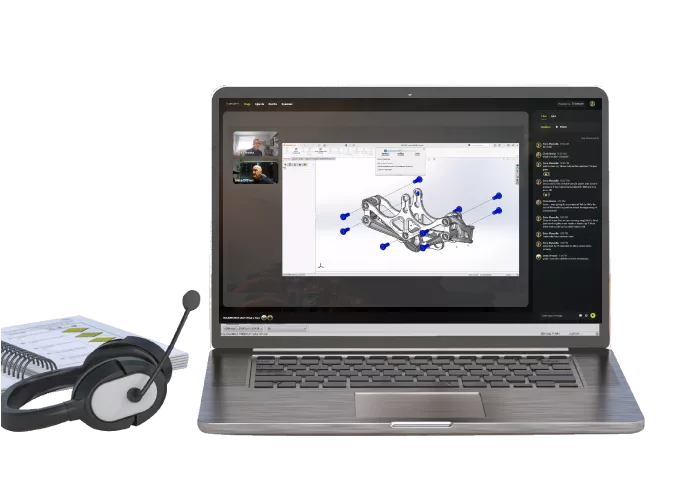

Engineering Webinars

Our team of experts host monthly engineering sessions covering everything from SOLIDWORKS tips and tricks, simulation analyses, 3D printing technologies, and more.Learn More >

Discover Advanced Design

All month long, discover exciting design tech that build upon SOLIDWORKS for quality & efficiency breakthroughs.Learn More >

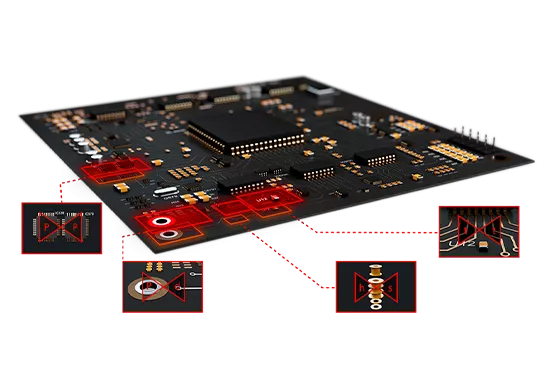

Next-GEN PCB DESIGN

Electromechanical product development is about to get easier than ever, thanks to the new partnership between Cadence and Dassault Systèmes.Learn More >

PROFESSIONAL TRAINING

SOLIDWORKS, 3DEXPERIENCE, CATIA and SIMULIA Professional Training coursess available from certified instructors.Get Details >

ONLINE STORE

Order 3D printing materials and consumables. Enroll in SOLIDWORKS online training classes and more.Shop Now >

Online Store

trusted

by industry leaders

trusted

by industry leaders

trusted partners

Collaboration and partnership with our customers is at the center of everything we do. With more than 35 years experience and tens of thousands of customers in high tech, medical, machine design, energy, and other industries. Empowering the Creation of Today's Products and Tomorrow's Innovations.