SIMULATION SERVICES

Advanced FEA & CFD for Better Product Engineering

Design Better Products with CAE Experts

Bringing a competitive new product to market is hard. Engineers have to create something the world has never seen before, and they have to be absolutely sure that it will work 100% of the time.

That’s a scary proposition.

How do you effectively manage this risk? Failure to do so will have serious consequences: production delays, lost contracts, failure in the field, expensive recalls, reputational damage; the list goes on.

We refer to simulation by many different names — CAE, FEA, CFD, numerical analysis, virtual testing, or prototyping — but it all means one thing: better engineering decision-making through computer prediction.

Confident & Bold Decisionmaking

Validate your designs with real-world simulations, reducing uncertainty and design iteration.

Reduce Bottlenecks &

Free Up Your Team

Offload complex simulations to our experts so your engineers can focus on big ideas.

![]()

Cost-Effective

Innovation

Reduce prototyping costs and accelerate time-to-market with virtual testing.

![]()

Scalable

Support

Whether you need one-time validation or ongoing simulation, we adapt to your needs.

“I have been working with GoEngineer for over a decade which is testimony of our relationship in and of itself.

Their customer service is second to none, always ready to jump on a project on short notice. They are thorough and expeditious in completing tasks and embrace the co-development mindset. Their partnership has saved us significant time and money in development and testing and allows us to maintain our place as a best-in-class medical device manufacturer.

I cannot recommend their services more highly and look forward to our continued collaboration.”

– Robert F.

R&D Engineering Manager

Fortune 500 Medical Device Company

| Internal CAE Resources | Simulation Consulting Services |

|

| Software & Tools |

|

|

| Computational Power |

|

|

| Expertise |

|

|

| Capabilities |

|

|

| Project Turnaround |

|

|

| Cost Efficiency |

|

|

| Risk & Accuracy |

|

|

| Scalability |

|

|

SIMULATION SERVICE CAPABILITIES

-

FEA Consulting

-

Don’t design in the dark. GoEngineer’s large FEA portfolio provides accurate and comprehensive engineering guidance to reliably improve engineering outcomes.

Our analysts have multi-decade careers in simulation consulting across many industries, and that experience and expertise is yours to take advantage of.

- SEE PORTFOLIO

-

CFD Consulting

-

CFD is sophisticated technology with innumerable applications and high computational demands. GoEngineer has the CFD capabilities and resources to help make it happen for you.

Our CFD experts will help you predict and understand complicated fluid flow scenarios, speeding up your design iteration and prototyping phases.

- SEE PORTFOLIO

Simulation Service Types

-

Project Analysis

"Does it pass the test?” GoEngineer can assemble the model, design the simulation, and give you the answer. Compare your options, validate your ideas, and hit your targets with confidence.

Engineering Analysis

Virtual prototyping using reliable, true-to-life CAE keeps engineers and companies on the right track when designing complex and interconnected products in increasingly competitive markets.

Read More...

-

Product Design & Development

Integrated design and development services. From research to production, GoEngineer's designers and engineers work side-by-side using the latest analysis and optimization tools to efficiently develop parts to specification.

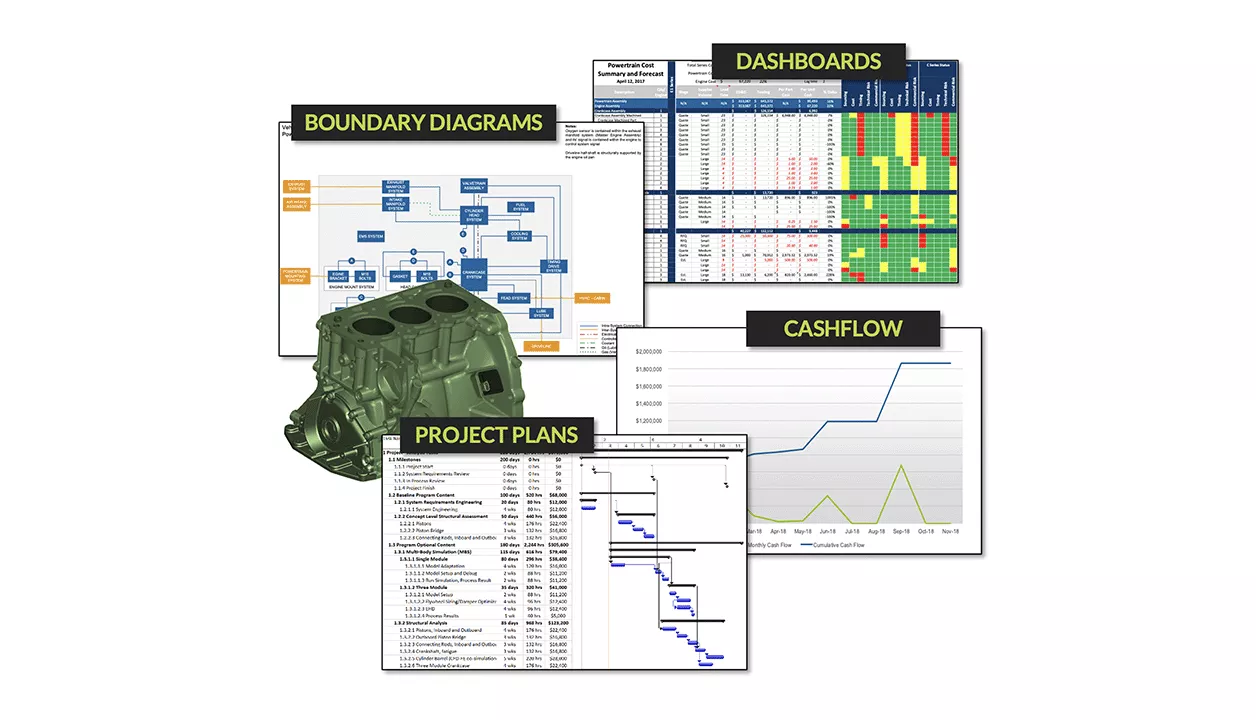

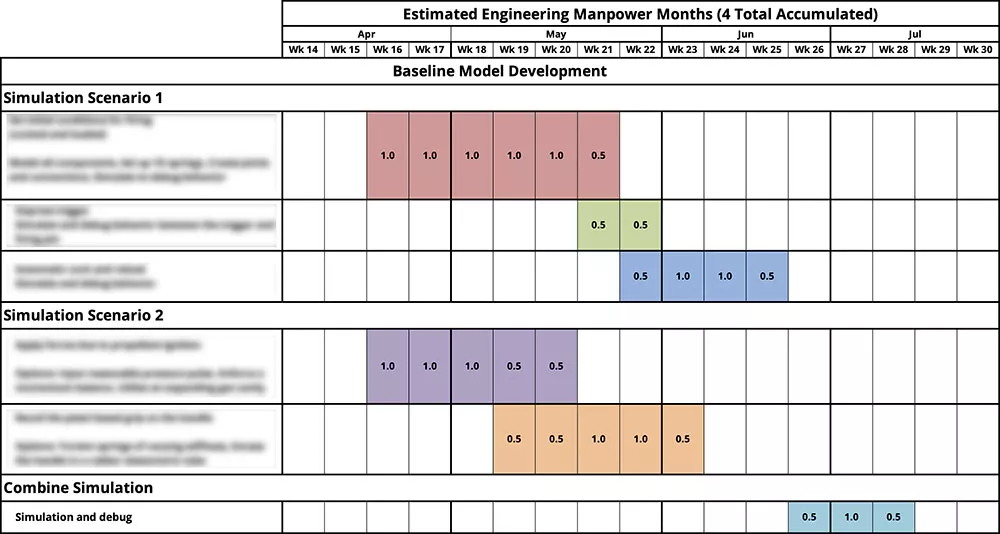

Project Planning

Detailed Gantt charts with resource and cost identification.Reliability Growth

Boundary diagrams, process flow, and failure modes effect analysis (FMEA).

Read More...Supplier Coordination

Prototypes, capability assessment, and cost analysis.Engineering, Cost, & Supplier Status

Concept sheets and customized management dashboards.Cost Forecasting & Tracking

Financial planning, tracking, and cashflow analysis.We Do Front End Engineering Design (FEED)

Cost-effective product development programs rely upon FEED to minimize total expenditures. Although the initial investment is typically higher (more up-front engineering), the process generally leads to reduced cost of product development and final products.FEED capabilities:

- Planning/costing

- Concept design/trade studies

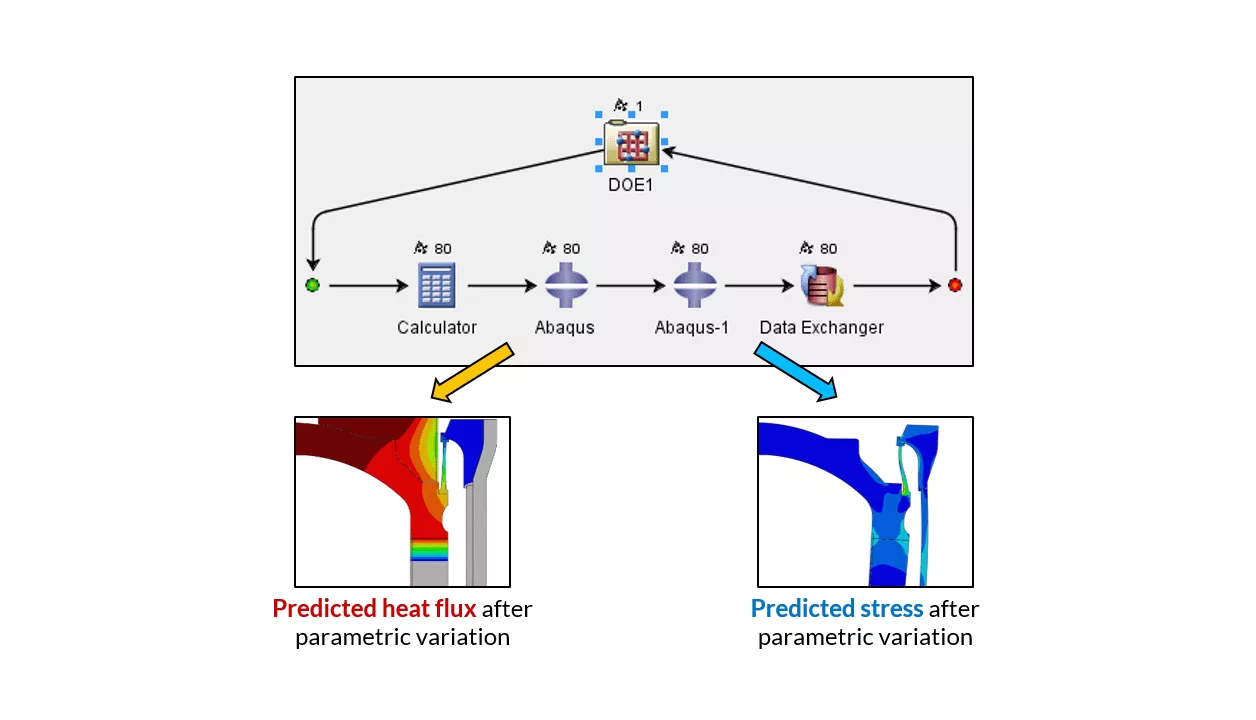

- Optimization/DOE

- FMEA/DVP&R support

-

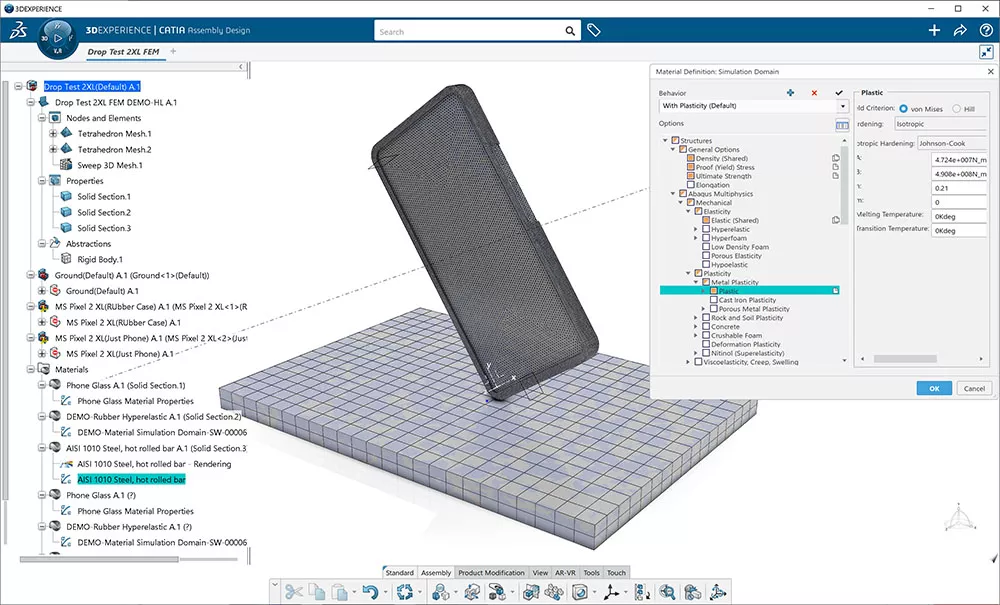

Physical Test Matching

Accuracy is essential to effective CAE, so we’ve made physical-to-virtual test correlation and material characterization two of our most practiced skills.

Material Characterization

Complex materials can be tricky for FEA, especially under extreme loading or environmental conditions or in composites. Clever modeling, sound data interpretation, and user subroutines can be used to reproduce nonlinear and situationally dependent behavior, like failure and degradation, complex layering, variable properties, etc.

Read More...Test Correlation

Many of our projects, especially those involving nonlinear dynamics, start with a physical test video. With the appropriate material properties, assembly connections and constraints, and an intelligent approach to model simplification, true-to-life simulation behavior is very achievable. From there, new design and analysis can be pursued with confidence.

-

Methodology Development

Creating a simulation that is complex, accurate, and efficient requires skill and experience. If the predictive model you require seems out of reach, GoEngineer can help. As consultants, we routinely use CAE software in creative ways to go beyond common analyses.

Cutting-Edge Simulation

Our expertise in a wide range of FEA and CFD tools can become your advantage. We can develop and train your analysis team on software and modeling methodologies that will lead to better engineering decision making.

Simulation Services Process

Consultation

It Begins with a Conversation

Your engineering and business needs are unique, and there are many ways that GoEngineer can help. We can integrate simple analysis, design experimentation, and virtual testing involving a variety of physics simulation at varying levels into your own processes and operations.

After an in-depth technical discussion, we'll provide the best personalized solutions from our service catalog to meet your goals.

Proposal

Know Exactly What You’re Getting

GoEngineer will build a detailed proposal reiterating your interests and what we’ll do to meet them. This document will include:

- Bulleted project scope, including analysis methods, purposes, and outputs

- Phased timeline and manpower (estimated)

- List of deliverables, obligations, and extended offerings

- Cost breakdown

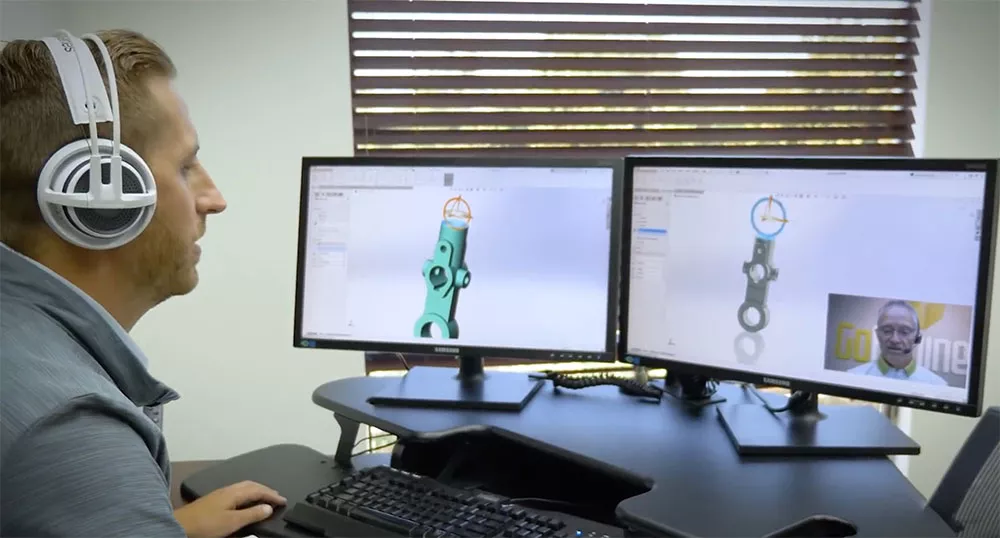

Communication

Dedicated Points of Contact

You will have a lead engineer and an overseeing engineering manager assigned to your project, with uninterrupted and open lines of communication.

Awareness from Beginning to End

We recommend weekly web meetings with your GoEngineer project lead and engineering manager to discuss the progress and direction of your project. These meetings can be extremely valuable, especially upon surprising analysis results.

Have CAE, Will Travel

GoEngineer personnel are also available for travel to in-person meetings with you and/or your customer.

Execution

Know Exactly What You’re Getting

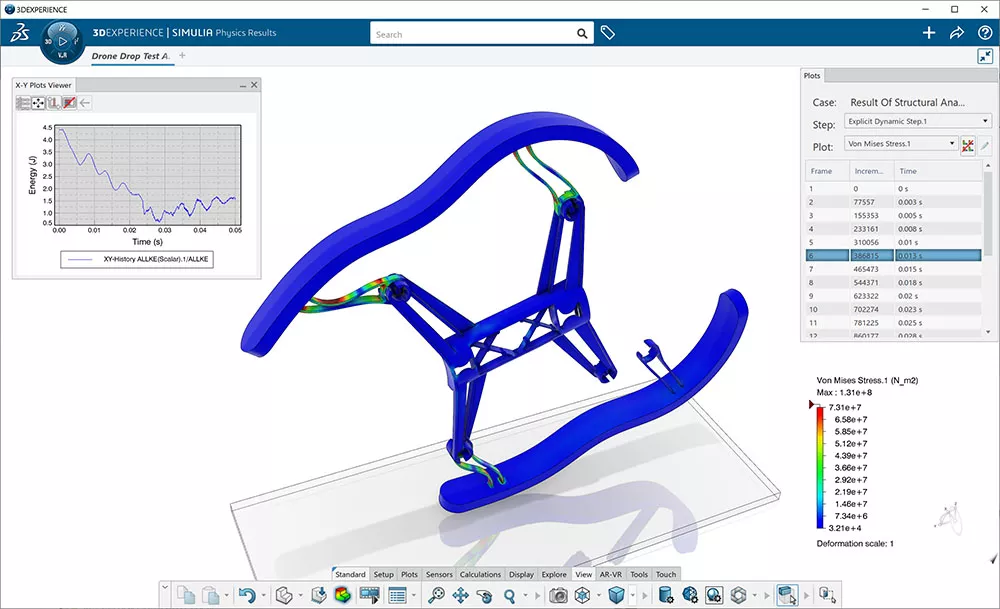

We build high-quality simulations to customer specifications using our extensive CAE software portfolio:

- Abaqus FEA

- fe-safe

- Tosca Structure

- Isight & SIMULIA Execution Engine

- FEMFAT Fatigue Software

- Simpack

- SOLIDWORKS Simulation

- SOLIDWORKS Flow Simulation

- SOLIDWORKS Plastics

- 3DEXPERIENCE STRUCTURAL

- 3DEXPERIENCE FLUIDS

- Ask for additional codes

Big Computing Resources for Fast Results

With high-performance local and cloud computing capabilities, we can support rapid iteration on very large analyses, like high-fidelity, multistep nonlinear static analysis, or full vehicle crash simulations.

Deliverables

Everything You Need for Better Decision Making

The GoEngineer CAE consulting team can produce a wide range of deliverables for you, as scoped out in your proposal:

- Simulation and technical presentations

- Image, video, and 3D interactive results

- Optimized 3D topology or design parameters

- Design/engineering recommendations

- Accounting of resources

- Functioning FEA & CFD models

- Solver output databases

- Documentation of methodologies

Next Steps

Building Upon Success

Some projects may be complete upon delivery, but it doesn’t have to stop there. Additional steps may include:

- Project retrospective

- Customer interface

- Additional iterations and studies

- Transfer of analysis files

- Training in methodologies used

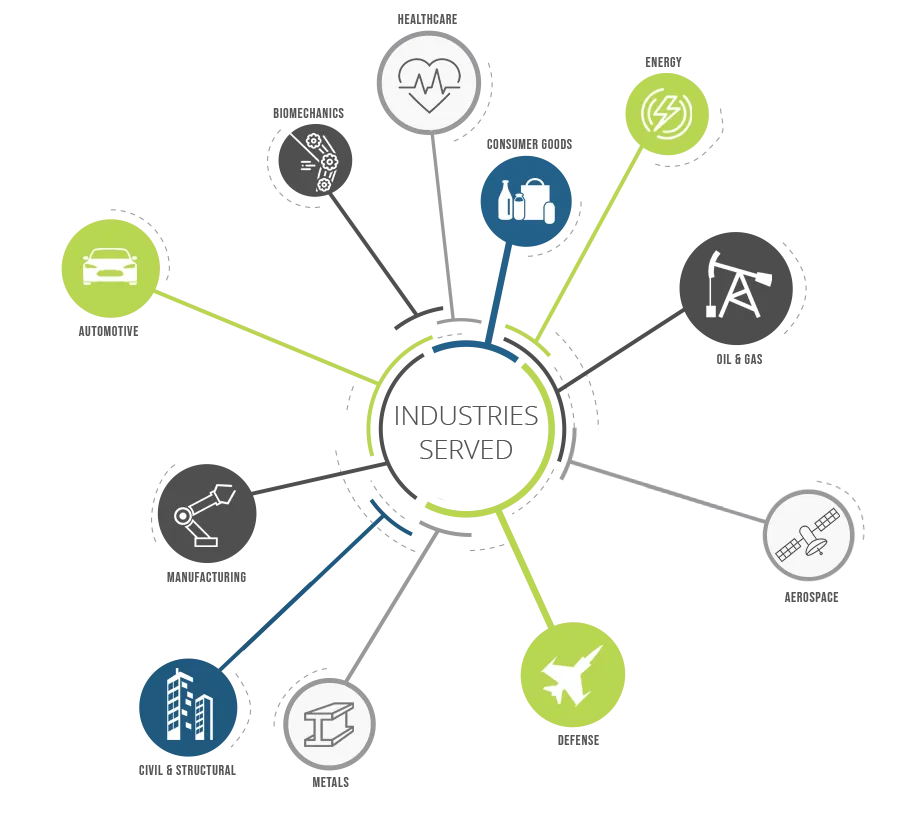

Industries Served

Who Can We Help?

We work across a broad range of industries that includes automotive, energy, oil and gas, aerospace and defense, civil and structural engineering, metals, machining and manufacturing, consumer goods and appliances, healthcare, and biomechanics; helping customers to leverage existing legacy and emerging simulation technologies.

We have experts in engineering, mathematics, and physics with proven experience in mechanical and structural engineering, metallurgy, computational fluid dynamics, high & low-frequency electromagnetism, multi-physics, multi-body dynamics, acoustics, tolerance management, and additive manufacturing.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services