3DEXPERIENCE

A web-based product development platform

What is 3DExperience?

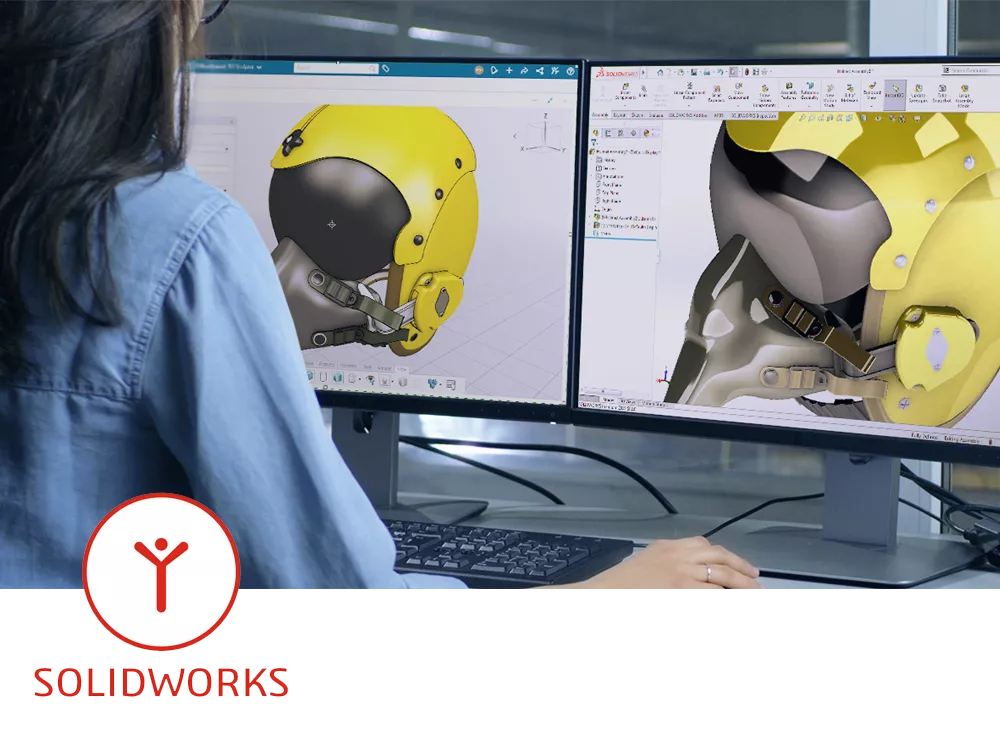

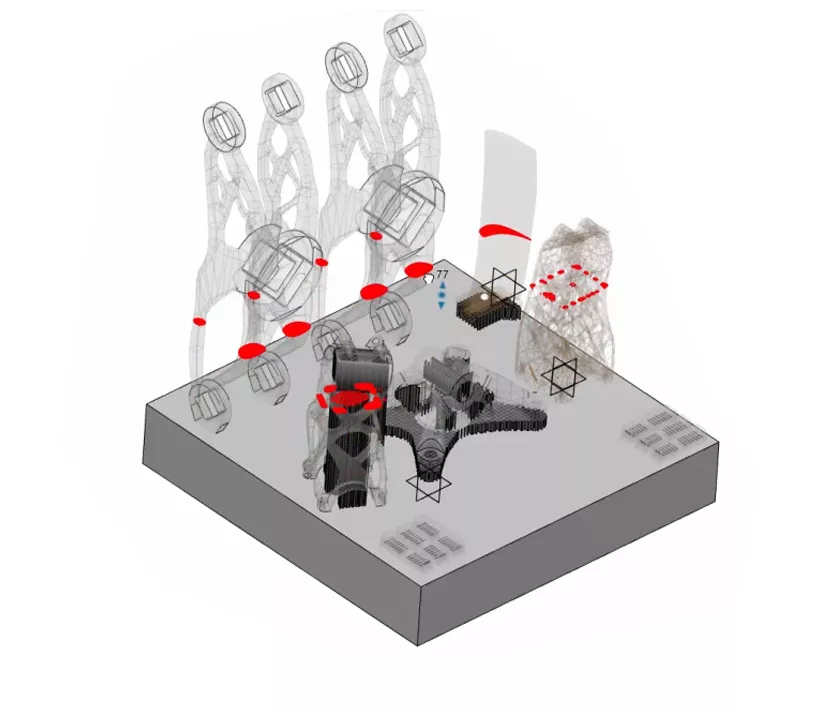

The 3DEXPERIENCE platform from Dassault Systémes brings all aspects of product development together, allowing users to develop and validate product designs in a collaborative environment. On a base level, the 3DEXPERIENCE platform is a collection of different apps that help users accomplish business-critical tasks. 3DEXPERIENCE solutions complement the SOLIDWORKS desktop tools and allow customers to collaborate on designs anywhere.

don't miss our upcoming webinar!

3DEXPERIENCE Platform: Leveling Up to Subdivision Modeling with 3D Sculptor

Tues, Feb 21, 2023 at 12pm PT

Sub Division Modeling is an entirely different approach than Mechanical Design. 3D Sculptor is a tool designed specifically to create organic shapes….a Mainstay for Industrial Designers, and a compliment to traditional product development.

Join us for a live webinar where we'll show the workflow used to create swoopy and exotic shapes WITHOUT relying on cumbersome, mechanical features like Lofts, Sweeps and Surfacing. We'll also demonstrate the process of how tools like SOLIDWORKS and Scupltor can utilize each others data in a fluid design process. Finally, we’ll look at some examples of where Sub D design can be used to tackle creations that are too difficult or simply not possible with todays CAD systems.

Report: Beat Bottlenecks by Uniting Teams and Improving Competitiveness

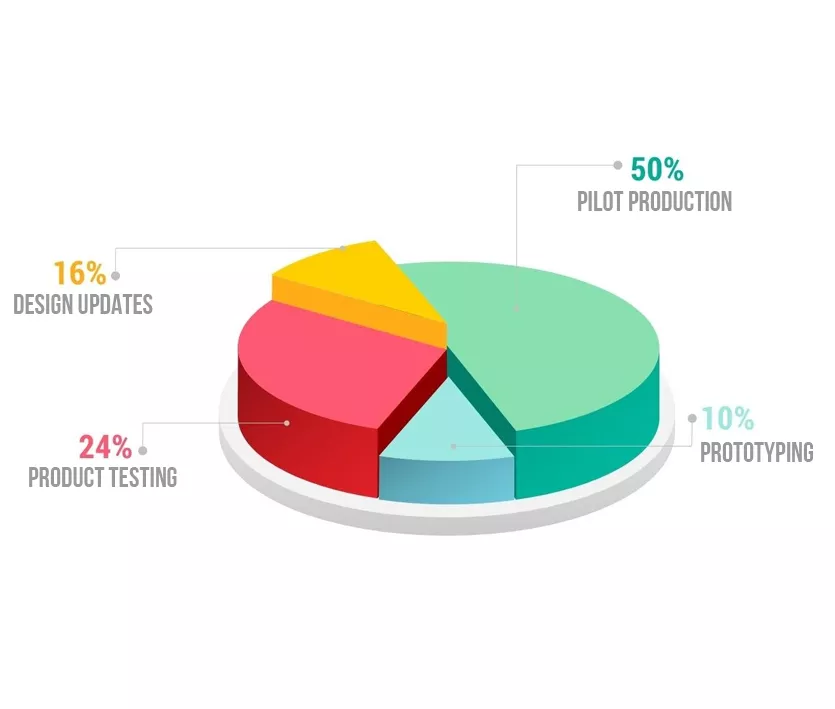

Given a whopping 99% of companies report suffering from delays in their design process, it's not surprising that many of them struggle with bringing innovative, cost-effective products to market.

Sound familiar? At least you're not alone. The good news is modern infrastructures are available to alleviate pressure associated with common design environments by enabling smooth collaboration across design and manufacturing teams, including global locations and third parties.

Read this eBook to understand what key bottlenecks are holding back your design process and learn the strategies to overcome them.

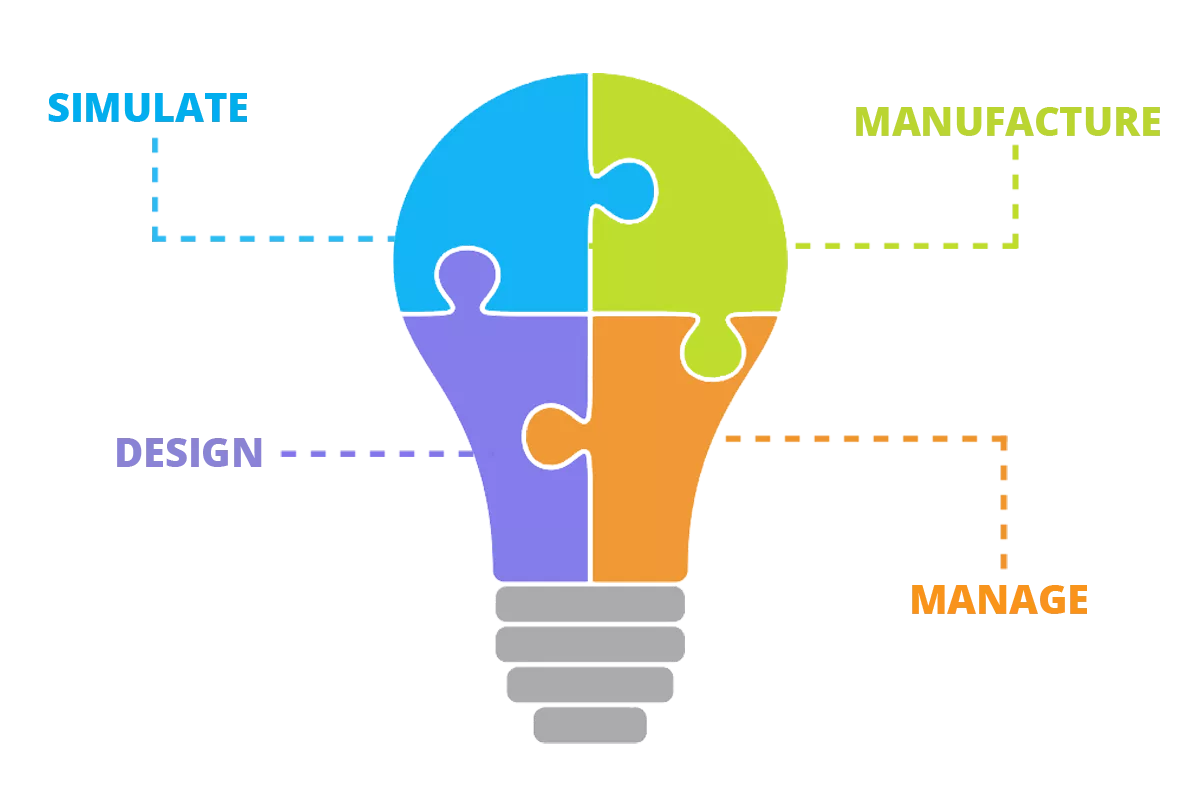

HOW IT WORKS

Step 1

Step 2

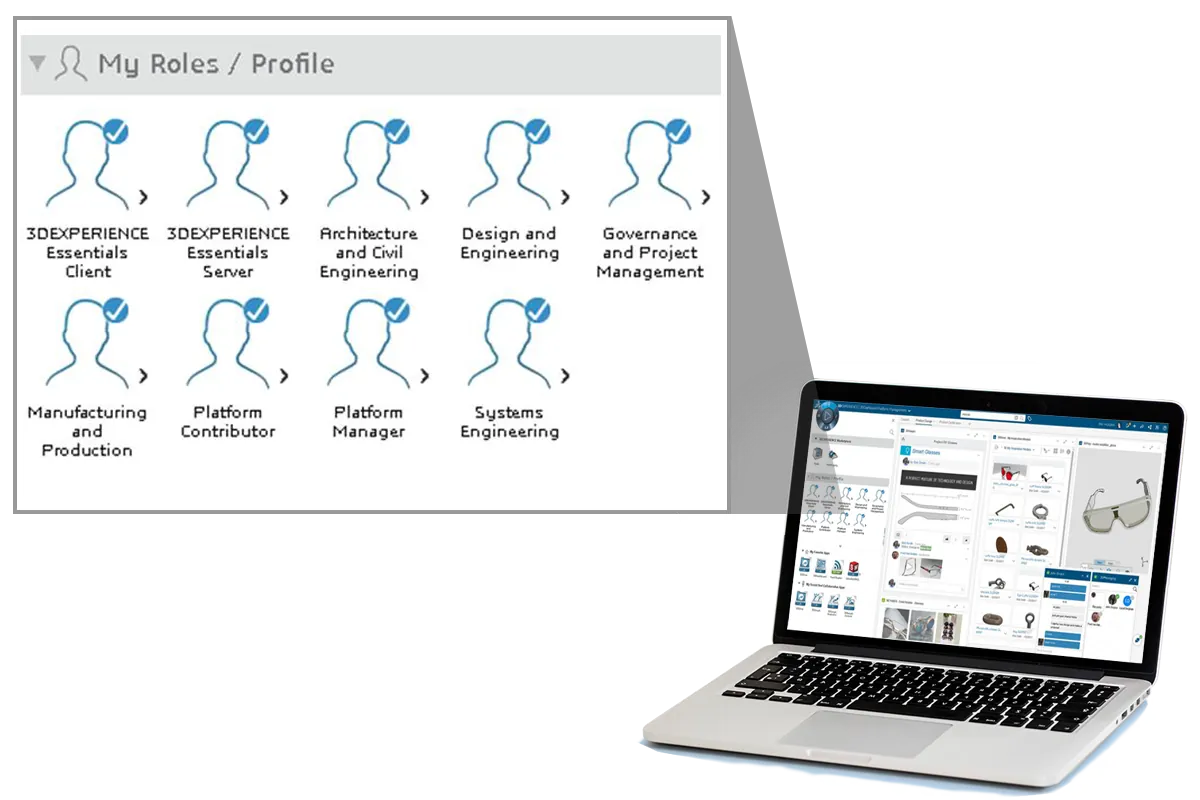

DEFINE ROLES

Once you determine your category, you can begin to define roles within your organization. With over 500 different roles, everyone at your company can collaborate on the platform with their own customized 3DEXPERIENCE dashboard.

Step 3

UTILIZE APPS

With your 3DEXPERIENCE roles established, you can unlock hundreds of category-specific apps, allowing you to collaborate with your team, manufacturers, and suppliers, and customers, to develop new products.

SELECT A Category

Begin your 3DEXPERIENCE journey here by selecting which stage of product development you need applications for.

Start your 3DEXPERIENCE path here if you need intutive apps to design products, parts and assemblies.

DESIGN

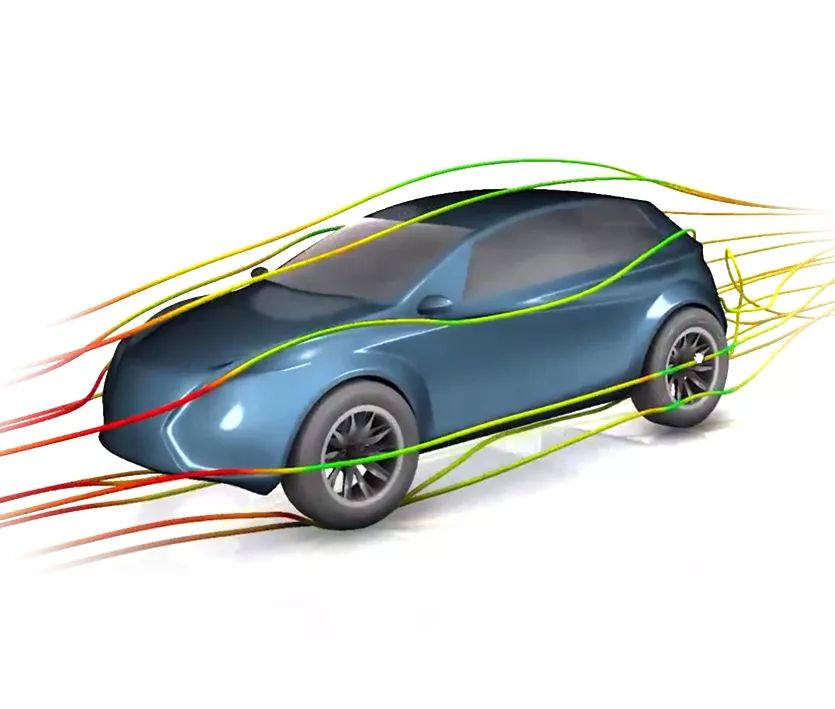

Have a designed product that needs simulation analysis and testing? Start your 3DEXPERIENCE path here.

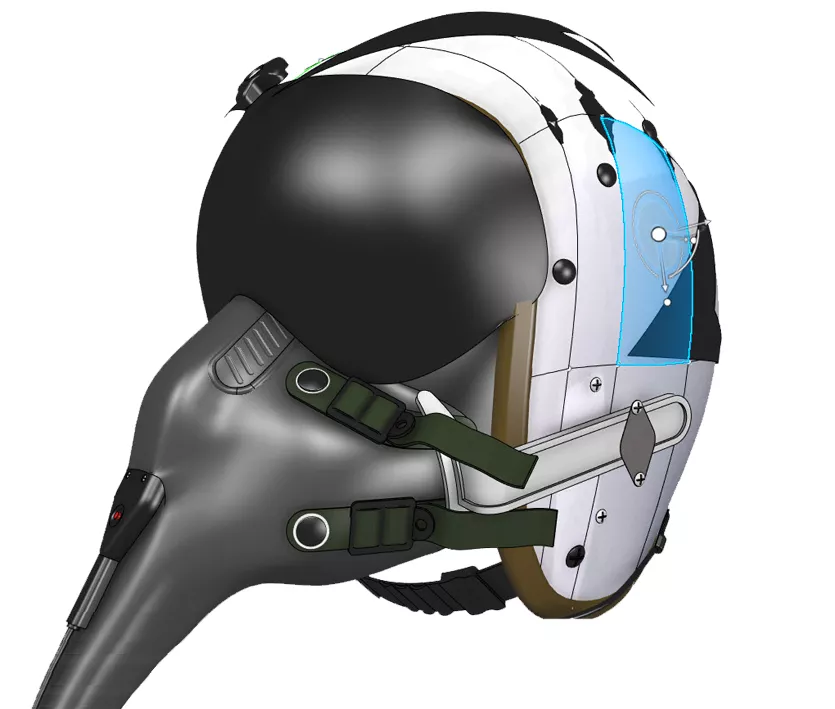

SIMULATION

Need tools to help plan and manage your development? 3DEXPERIENCE apps powered by ENOVIA can assist you.

DATA & LIFECYCLE

Ready to begin manufacturing your product? Utilize DELMIAWORKS specifically designed for manufacturing.

MANUFACTURING

BENEFITS

REal-Time Collaboration

The 3DEXPERIENCE platform empowers organizations to collaborate in real-time from any device, connect with customers and suppliers, and track progress to deliver unique products and customer experiences.

POWERFUL CLOUD READY TOOLS

The 3DEXPERIENCE platform complements and strengthens the SOLIDWORKS you love today by connecting you with robust data and lifecycle management, simulation, and manufacturing applications in the cloud.

SOLUTIONS THAT EVOLVE

The 3DEXPERIENCE platform is ideal for organizations of any size. As your company's needs evolve, you can access a diverse portfolio of solutions to manage every aspect of your product lifecycle.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services