SOLIDWORKS CAM

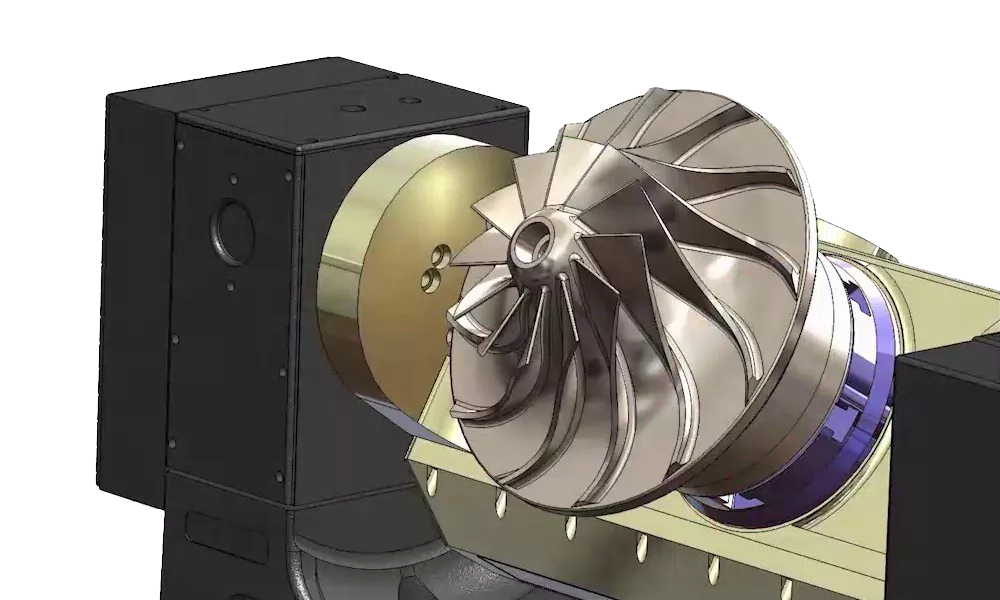

An integrated solution from design to manufacture

What is SOLIDWORKS CAM?

SOLIDWORKS CAM is an integrated CAM solution available to all SOLIDWORKS Desktop licenses on subscription, allowing for 2.5 and simple 3-axis toolpath creation for mill machines. Powered by HCL CAMWorks, the original SOLIDWORKS Gold Partner, SOLIDWORKS CAM offers a similar interface that makes learning easy.

With a common platform and a simpler workflow, SOLIDWORKS CAM unites both design and manufacturing teams, resulting in a better CNC experience. This integrated solution also allows for parametric updates to toolpaths and skips timely exports to third-party software. SOLIDWORKS CAM learns as you program, allowing you to reuse programming data on previous parts to make future parts programmable with just a few clicks.

For those needing more advanced capabilities, CAMWorks provides the next tier of software. It offers enhanced features and flexibility, making it the ideal step up for complex machining requirements. CAMWorks includes additional functionalities such as 3-axis milling with undercutting, 4-axis and 5-axis simultaneous milling, mill-turn capabilities, and synchronous machining for lathes. These advanced features enable users to tackle more sophisticated and demanding manufacturing tasks with greater efficiency and precision.

don't miss these upcoming webinars!

Mastering CAM Integration for SOLIDWORKS

Tue, Aug 29, 2023 at 8am PT

Integrated CAD/CAM saves time and money by eliminating the need to maintain separate CAD and CAM files, and full associativity with your SOLIDWORKS model provides automatic updates to toolpaths and G-code whenever design changes occur. If you are looking for a new integrated CAD/CAM solution or are ready to increase your productivity, join this webinar to see the benefits achieved with integrated CAD/CAM for SOLIDWORKS with SOLIDWORKS CAM and CAMWorks.

Advancing Beyond Entry-Level CAM with SOLIDWORKS Integration

Tue, Sept 7, 2023 at 11am PT

CAD/CAM software is a vital component in getting the most from your CNC machine tools and choosing an inexpensive system can often cost more in the long run. Periodically evaluating the CAD/CAM technologies available today makes sure you stay competitive. Join this webinar to gain a better understanding of when it makes sense to look beyond entry-level CAM.

PACKAGES AVAILABLE

-

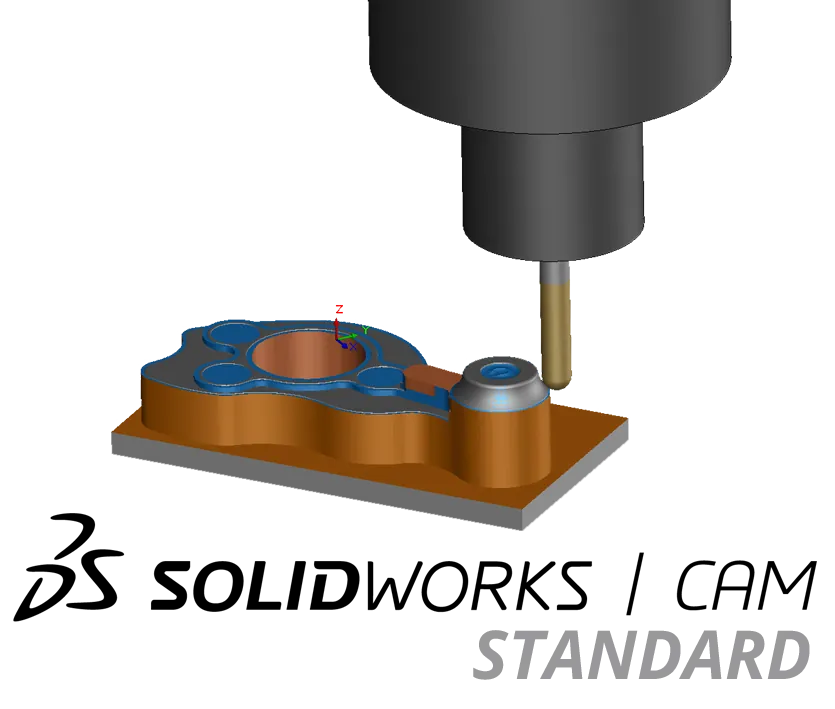

- SOLIDWORKS CAM Standard features the tools necessary for 2.5-axis CNC milling of parts. Roughing, finishing, 3D edge breaks, and hole processing can all be accomplished without leaving the SOLIDWORKS 3D CAD environment.

-

-

Most flat-bottom geometries, such as pockets, slots, and bosses are 2.5-axis features. CAM Standard will generate g-code to move through the Z-axis but most cuts will be in the XY plane.

-

CAM Standard will handle all types of hole operations: drilling, reaming, boring, tapping, and thread milling.

- In addition to 2.5-axis milling, CAM Standard will also provide basic 3-axis milling tools. Whole-part roughing and Z-level finishing is included to handle occasional 3D toolpath requirements.

-

Most flat-bottom geometries, such as pockets, slots, and bosses are 2.5-axis features. CAM Standard will generate g-code to move through the Z-axis but most cuts will be in the XY plane.

-

-

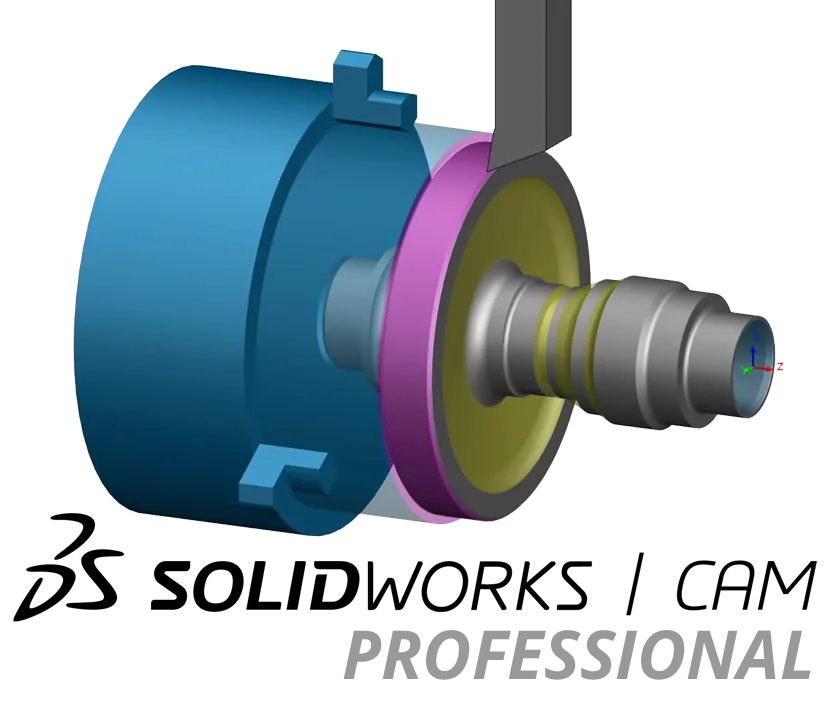

- SOLIDWORKS CAM Professional expands on the abilities of SOLIDWORKS CAM Standard. In addition to all of the 2.5- and 3-axis capabilities, an upgrade to SOLIDWORKS CAM Professional will include:

-

Assembly Mode

There is no way to avoid the need for work holding – parts must be held down – but we can avoid costly collisions between tools and fixtures by planning ahead. Programming within a SOLIDWORKS assembly is the best way to ensure your toolpaths do not come into contact with anything but the stock material. Assemble your setup virtually using the native SOLIDWORKS CAD mating tools and simply assign parts as Fixtures to force toolpaths to avoid them.4- & 5-Axis Indexing

Automatically generate rotational A/B/C codes to swiftly move between setups. Programming for indexers and trunnions is simple and straightforward with SOLIDWORKS CAM Professional.VoluMill

VoluMill leads the industry in high-speed machining (HSM) toolpath technology, and it is built right into SOLIDWORKS CAM Professional. A dedicated Feeds & Speeds wizard will help you create toolpaths that are not only faster but safer and less harsh on your machine tool. Tool life goes up, cycle time goes down, and you’re more competitive than ever with VoluMill.

Turning

Standard 2-axis lathes can be programmed in CAM Professional. Toolroom or slant-bed lathes with X and Z control are compatible. Program all types of outside diameter (OD) and inside diameter (ID) work, including grooving and threading.

Configurations

CAM configurations work the same way regular SOLIDWORKS configurations work – allowing different “versions” within the same file. Those versions might differ in geometry or just the type of code required. For example, if initial cuts were to be made on a lathe and then the part is transferred over to a mill for finishing, both lathe and mill programming would be necessary. CAM Professional provides the flexibility to handle all of that within the same file, simplifying file management and minimizing the chance of human error.

-

Accelerate Machining Productivity with HCL CAMWorks

CAMWorks provides SOLIDWORKS-integrated, feature-based CAM tools that help you:

- Program smarter

- Machine faster

- Improve quality and consistency

Learn more about the large CAMWorks portfolio and how it helps manufacturers in this informative brochure.

SOLIDWORKS CAM vs CAMWORkS

| AVAILABLE TRAINING |

SOLIDWORKS CAM |

HCL CAMWORKS |

FEATURES |

Standard | Professional | Standard | Milling Standard | Turning Standard | Milling Professional | Turning Professional | Premium | Bundle Add-Ons |

| 2.5 Axis Milling Plus* |

|

|

|

|

|

|

|

|

|

| Cimco Editor/DNC |

|

|

|

|

|

|

|

|

|

| 2.5 Axis VoluMill |

|

|

|

|

|

|

|

||

| Probing |

|

|

|

|

|

|

|

||

| 2.5 Axis Surface Machining |

|

|

|

|

|

|

|

||

| 4/5 Axis Indexing |

|

|

|

|

|

|

|

||

| Assembly Machining |

|

|

|

|

|

|

|

||

| Turning |

|

|

|

|

|

|

|

||

| 3 Axis Milling - Level 1* |

|

|

|

||||||

| 3 Axis Milling - Level 2* with Undercutting |

|

|

|||||||

| Sub-Spindle |

|

|

|

|

|

|

|||

| Mill-Turn |

|

|

|

|

|||||

| Synchronous Machining for Lathes |

|

|

|

||||||

| 4 Axis Milling (Add-On to Milling Pro only) |

|

|

|||||||

| 5 Axis Simultaneous |

|

||||||||

| Rotary Milling |

|

|

|

|

|

|

|||

| Virtual Machine Standard |

|

|

|

Products available as Bundle Add On

- 3 Axis VoluMill

- Virtual Machine Professional

- Virtual Machine Premium

- PrimeTurning™

- CAMWorks Utilities

Additional Product Options

- Wire EDM

- NestingWorks

- CAMWorks ShopFloor

* 2.5 Axis Milling Plus includes 2.5 Axis Milling plus Area Clear Roughing, Flat Area and Z-Level Finishing

* 3 Axis Milling L1 includes all 2.5 Axis functionality, plus Pattern Project, Constant Step, Pencil Milling, Curve Project, and Legacy Rough & Finish Mill

* 3 Axis Milling L2 includes L1 functionality plus Undercutting, Fillet Machining, and NURB Surface Machining

- PrimeTurning™ is a Sandvik Coromant product.

Tools

Parametric Programming

SOLIDWORKS CAM is an integrated CAM solution, which allows users to program by referencing faces, edges, and other geometry on your CAD files directly in SOLIDWORKS. Changes to your design are instantly recognized by SOLIDWORKS CAM and toolpaths are updated automatically.

More Efficient Over Time

SOLIDWORKS CAM learns your machining style as you program each and every part. Save your strategies for machining into the Technology Database, which can be quickly reapplied to future parts, significantly reducing programming time.

Tolerance Based Machining

Take advantage of MBD and toleranced dimensions in SOLIDWORKS! SOLIDWORKS CAM will use this information to suggest appropriate machining strategies automatically, streamlining the design to manufacturing process.

NC Editor

In addition to an in-software simulation, the included NC Editor with Backplotting can help verify a part has been programmed correctly, avoiding costly mistakes when taking the program to a CNC Mill.

Auto Feature Recognition

SOLIDWORKS CAM can help you program your part by automatically recognizing where it needs to place toolpaths. The technology behind this tool has been available in SOLIDWORKS for a long time in the form of FeatureWorks, an add-in that attempts to rebuild a SOLIDWORKS Feature Tree on imported solids such as .iges and .step file.

Frequently Asked Questions

If the file type can be brought into SOLIDWORKS as solid bodies or surfaces, it can be programmed.

Post processors are information translators, converting SOLIDWORKS CAM data into G-Code that your machine controller can read. SOLIDWORKS CAM comes with many standard post processors, but custom posts can be purchased and supported through GoEngineer for more specialized needs.

SOLIDWORKS CAM Features

Full Integration

Fully integrated within SOLIDWORKS, this knowledge-based machining technology allows designers to integrate design and manufacturing processes all under one system. There is no need for separate software programs (or even hardware) and needlessly worrying about file translations or incompatibility issues between different software platforms. Once SOLIDWORKS modeling is complete, simply switch over to the SOLIDWORKS CAM environment with minimal loss of time and start creating toolpaths and then validate via Simulate Toolpath and output NC code with ease.

CAD Model & CAM Data are Parametrically Linked Together

Make a change to the CAD model and SOLIDWORKS CAM will update accordingly. Any changes affecting the SOLIDWORKS CAD model will directly affect the SOLIDWORKS CAM toolpath. Save time, money, and generate updated toolpaths all with a few mouse clicks!

Advanced Feature-Based CAM Technology

- Automatic Feature Recognition. This well-proven feature easily recognizes prismatic shapes such as holes, pockets, and bosses of your CAD model and generates customizable, efficient toolpaths for fast post processing of NC code. This technology even leverages SOLIDWORKS parametric information (e.g., Hole Wizard) and selects the proper cutting tools to generate NC code per your company’s standards and/or best practices.

- Interactive Feature Recognition. For users who prefer to utilize their own custom workflow (‘program your way’), Interactive Feature Recognition offers customization, flexibility, and simple ease-of-use to generate powerful and efficient toolpaths with a few mouse clicks.

Toolpath Simulation

Using the integrated simulator, designers can verify the correct machining strategies and setup information for each component produced.

Knowledge-Based Machining

The Technology Database, or “TechDB”, is the “brains” behind SOLIDWORKS CAM. This database allows you to create, edit, and save SOLIDWORKS CAM data. It then leverages that information for future programming projects of automation, efficiency, and high-performance toolpaths. Knowledge-Based Machining allows you to fully customize (create, edit, and save) your company’s standards and best machining practices all in one location (Technology Database). SOLIDWORKS CAM then leverages information from the Technology Database for reuse to create powerful, high-performance toolpaths that maximize efficiency and automation.

CAD Agnostic

Collaboration between other CAD programs is easy using SOLIDWORKS CAM as this program leverages its Feature-Based technology. Simply use your existing SOLIDWORKS model or import (*.STEP, Parasolid, IGES, etc.) into SOLIDWORKS the solid model from a different CAD platform and easily create your toolpath information.

ADDITIONAL CAM DOCUMENTS

SOLIDWORKS Services:

Utilize GoEngineer’s Award Winning Support & Training for SOLIDWORKS

Award Winning Technical Support

GoEngineer's extensive SOLIDWORKS technical knowledge and world class support can help you succeed with SOLIDWORKS. Our award-winning team is ready to help you with any task you may have. Using state-of-art remote assistant technology software allows our team to solve most issues within one session. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

- 125+Certified Technical Specialists

- Email, Phone and Chat Support Available

- 98% Exceptional Customer Service Rating

PROFESSIONAL SOLIDWORKS TRAINING

GoEngineer offers online and classroom professional SOLIDWORKS training for organizations and individuals. All our instructors are SOLIDWORKS certified and teach thousands of students each year world wide. The curriculum is very diverse with numerous certified SOLIDWORKS courses to choose from. Each student will receive a Course Completion Certificate and preparation materials for SOLIDWORKS certification.

- Increase Your Earning Potential

- Led by Certified SOLIDWORKS Instructors

- Smaller Classes with Focused Attention

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services