Materialise

Comprehensive 3D Printing Software

Now Serving US & Canada

Now Serving US & Canada

The Backbone of the 3D printing world

Materialise software tools work to manage additive manufacturing processes with efficiency and intelligence. With a range of products that span the 3D printing workflow, Materialise allows users to manufacture at the highest standards for demanding industries.

30 Years of Additive manufacturing Experience

TOOLS

Materialise

Materialise

Magics

Prepare your part for 3D printing with the industry-leading data preparation and STL editor software. Convert files, correct errors, edit designs, and prepare your build platform.

Materialise

Build Processor

Get your 3D printer and software communicating seamlessly with a custom fit build processor for your additive manufacturing machines.

Materialise

3-Matic

Clean up rough data or convert your mesh back to CAD with 3-Matic, a premium and versatile tool to make design modifications at the mesh level.

Materialise

e-Stage

Automate the creation of support generation to radically cut your design preparation time.

MATERIALISE Features

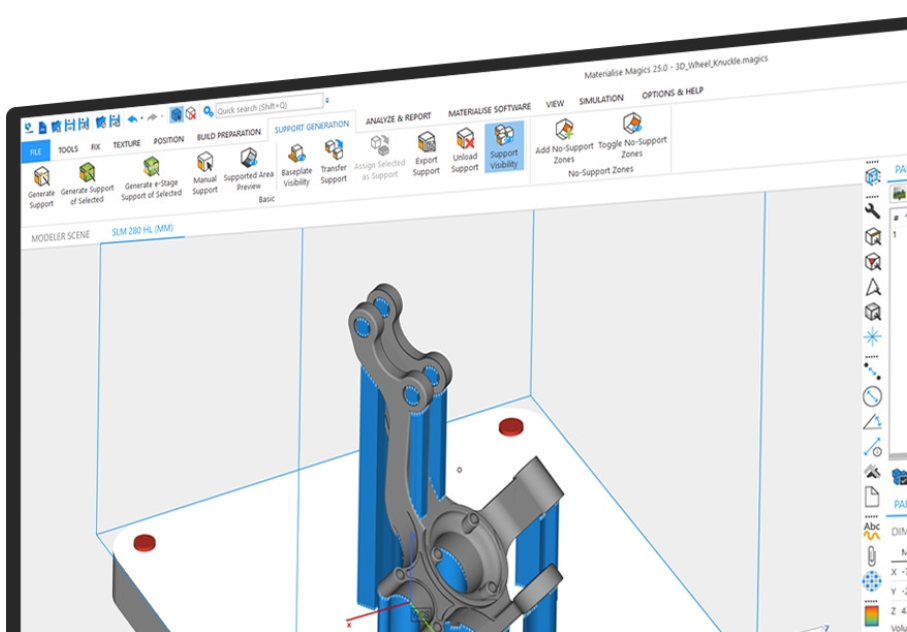

Materialise Magics

The Most Powerful 3D Printing Data Preparation Software

Materialise Magics makes prepping a 3D design file for printing easy, intelligent, and fast. Magics is a smart, versatile data preparation and STL editing software for 3D printing and additive manufacturing. The powerful industry-leading software walks the operator through every step of the 3D printing workflow.

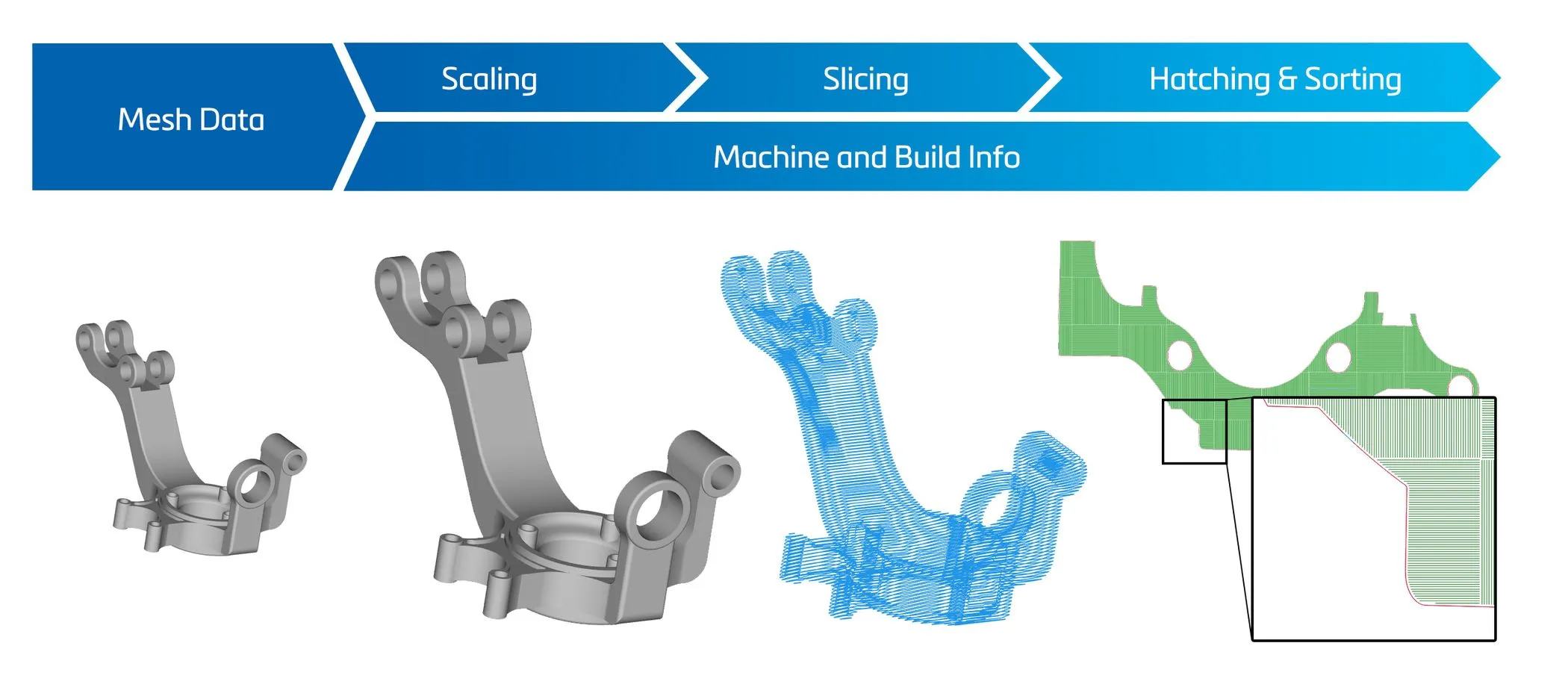

Materialise Build Processors

Tailor-Made Software For Over 130+ Additive Manufacturing Technologies

Each 3D printer has unique parameters and processes that need to be taken into account when designing and printing parts. With a Materialise Build Processor, you can ensure seamless communication between your additive software and hardware. With an intuitive interface operators can:

- Translate 3D data to machine-specific print instructions

- Leverage industry-standard software, tailored to each unique printer in your lab

- Process large, complex files

- Take advantage of advanced, multicore slicing algorithms

Materialise e-Stage

Generate Supports in Under 3 Minutes

Key features and benefits include:

- Reduce design time

- Eliminate print failures caused by human error

- Improve resin drainage

- Minimize support contact points

- Leverage the Gusset support type

- Run on over 40 machines, and 40+ material types

- Print complex parts fast

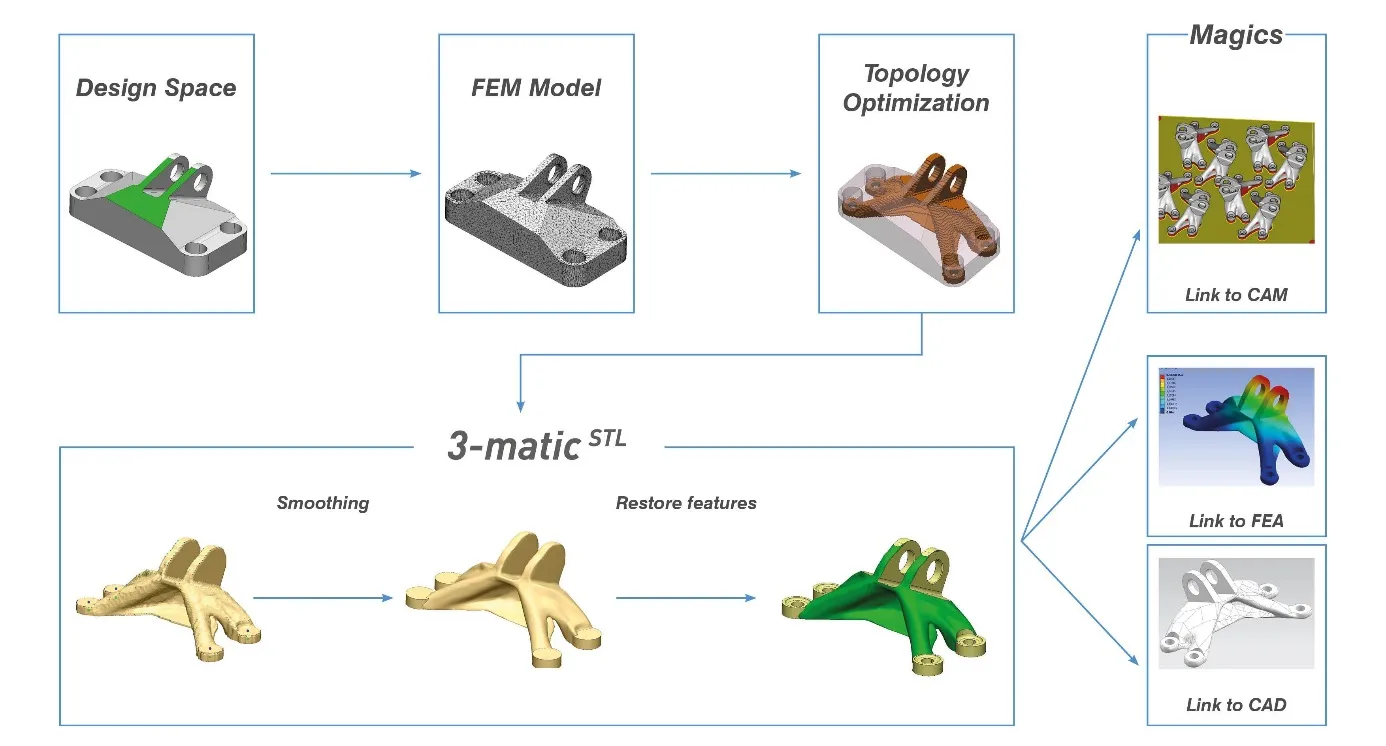

Materialise 3-Matic

Clean Up Rough Data in Hours – Not Days

3-Matic is a Windows-based program that allows you to execute design changes directly on STL mesh files. The functionality is easy to use for anyone familiar with Windows or CAD. 3-Matic offers a powerful workflow improvement for engineers struggling to efficiently implement topology optimization. A common struggle for topology optimization is that it takes a lot of time to convert the optimized files back to a computer-aided design (CAD) format, with 3-Matic this can be done in hours.

ADDITIONAL 3D Printing RESOURCES

AWARD-WINNING TECHNICAL SUPPORT

GoEngineer’s extensive technical knowledge can assist with your additive manufacturing needs. Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

3D Printing Courses

Learn to utilize all features and tools of Stratasys commercial 3D printers with GoEngineer additive manufacturing on-boarding training and 3D printing courses. Take advantage of our 3D printing team of experts to help launch all your 3D printing capabilities.

3D PrintING SERVICES

No matter the size, quantity, or complexity of part(s) needed, GoEngineer can help you! Take advantage of our 3D Printing Services to help your organization produce the best parts and prototypes available on the market.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services