SOLIDWORKS PDM

Securely Store Design Files and Related Data

What is solidworks PDM?

PDM stands for - Product Data Management.

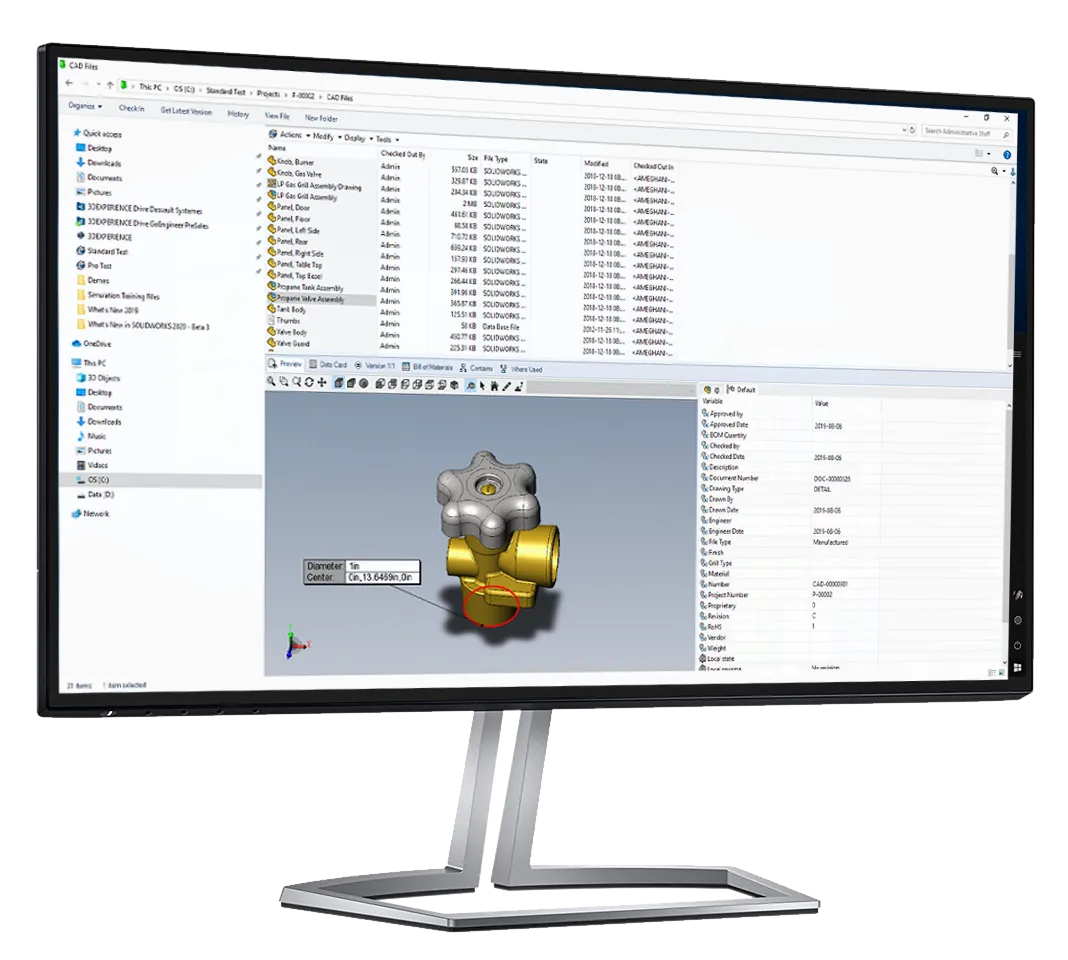

PDM is a secure data vault for all your CAD and design process information. A fully configurable environment, SOLIDWORKS PDM enables your teams to securely store design files and related data for fast retrieval. Eliminate concerns over version control and data loss and collaborate on designs across multiple locations with SOLIDWORKS PDM.

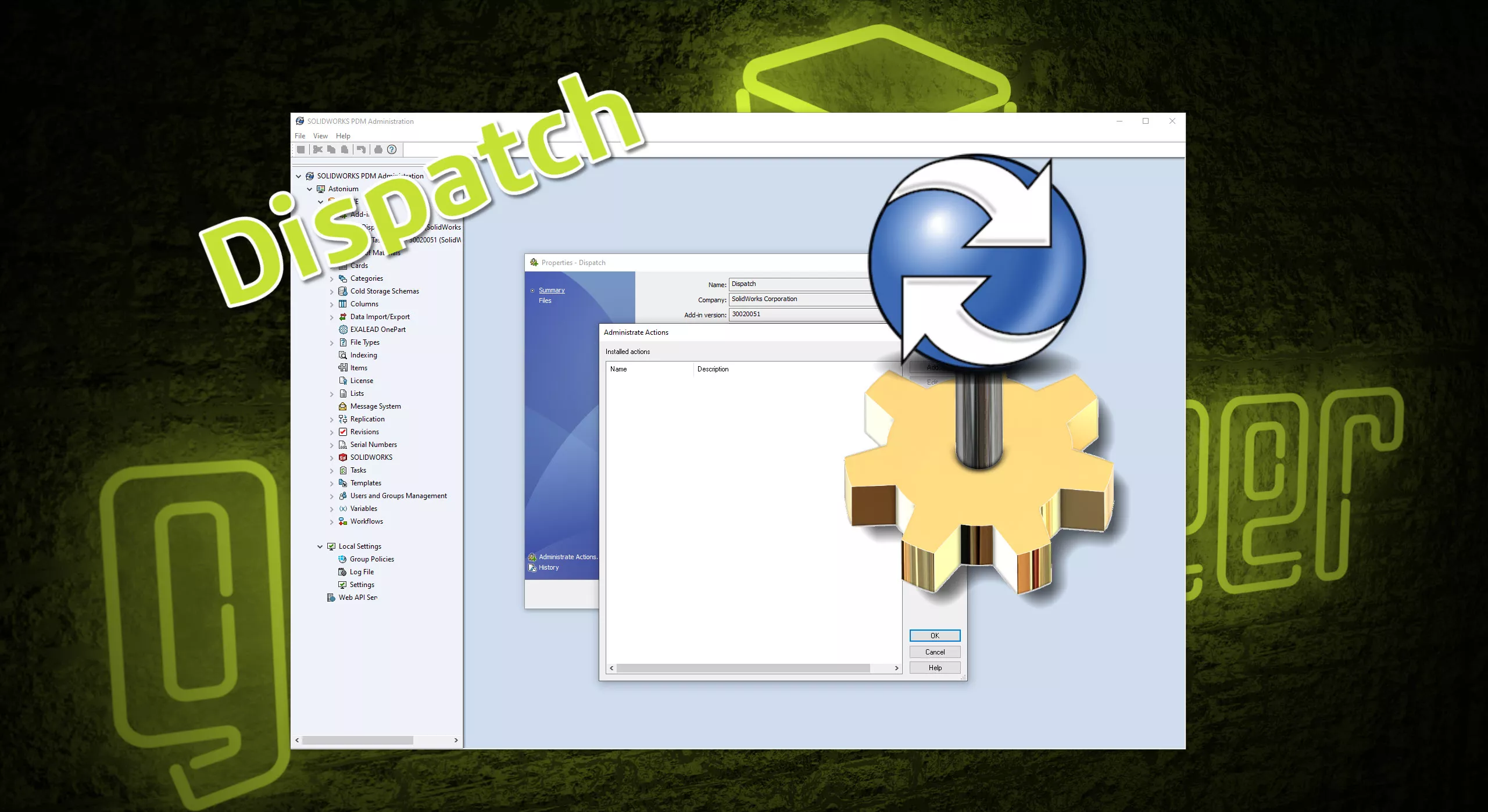

don't miss our upcoming webinar!

Using PDM Professional Dispatch

Wednesday, December 14 @ 12pm PT

Join us for this live webinar where attendees will learn and see demonstrations of building out real world examples of using the Dispatch automation in a PDM Professional environment. We will be discussing the general overview of Dispatch build logic, typical action setup, expanding simple builds and showing tips and tricks to build into the Dispatch action sequence.

How Do I Get Started?

Installation, process configuration, data migration, and user training… Implementing a data management tool into your company can seem like a daunting task.

Fortunately, the expert PDM Implementation team at GoEngineer is here to help. Learn about our proven process that ensures your SOLIDWORKS PDM system is set up right the first time.

24 TIPS TO MASTER SOLIDWORKS PDM

SHORTCUTS ⋅ SEARCHING ⋅ PDM ADD-IN

24 of our expert tips to help you master using SOLIDWORKS PDM. Improve performance, find files faster, work like a pro.

Tools

Revision Control

Managing changes to engineering designs is a necessary evil that we can't escape. SOLIDWORKS PDM provides the tools to tie true Revisioning into processes, and the ability to track the history of those changes throughout the life of a part or assembly. Having Revisions tied into PDM workflows takes a big portion of the management off the user and lets the system keep track of things.

Workflow Communication

The days of being able to talk around a cubicle wall are few and far between. Today's world requires quick and efficient electronic communication that can reach people who aren't even in the office. PDM Workflows can be built to mimic engineering processes, and the built-in notification system can notify the right people (at the right time) to ensure that designs and/or documents keep moving through the process.

Multi-User Collaboration

Parallel efforts will always yield faster results than serial tasks. SOLIDWORKS PDM facilitates parallel design efforts by allowing multiple designers to work on different components of the same top-level assembly at the same time. Updates can be checked in and designers can see each other's changes quickly and easily.

Web Access

We live in a mobile world, and it isn't always convenient to get to a desktop computer and access your engineering files. SOLIDWORKS PDM Web2 program gives us the ability to work in our PDM vault through a web browser. This on-the-go capability lets us see and review files and move them through workflows without a desktop client. Your suppliers can also be granted access directly to your CAD files without having PDM installed - anywhere in the world!

Advanced Searching

We all love the green Windows search bar that gives us time to grab a cup of coffee while it searches for our files (and never finds them), right? Not so much. SOLIDWORKS PDM leverages the power of Microsoft SQL Databases to organize information about our files and give us accurate search results - lightning fast. With SOLIDWORKS PDM, you're no longer handcuffed to search just by filename. Any attribute set up within PDM such as Part Number, Description, or Material can be searched with a high degree of precision and speed.

Reference Management

"That guy doesn't even work here anymore, why is SOLIDWORKS looking for a file on his desktop?!" Sound familiar or similar to an error you've experienced before? With SOLIDWORKS PDM these types of reference issues are a thing of the past. SOLIDWORKS PDM manages your file references and parent/child relationships for you, so it no longer matters if you move a file to a new folder or rename it outside of SOLIDWORKS. PDM knows the changes you made and ensures things stay intact.

File Standardization

Is your CAD folder structure out of hand? User and Group permissions in SOLIDWORKS PDM can determine who can make new folders, where they can make them, and what they can put in them. Additionally, PDM Templates can be used to generate standard sets of folders for each new project and ensure compliance with a defined structure.

Branch & Merge

Sometimes with a released product design an engineer may want to explore new concept ideas but may not want to work on the released design. With the Branch and Merge capabilities in PDM Professional designers can branch from an existing design and then later choose to merge that back into the parent as a new version or choose to keep it as a separate design that can follow its own path in PDM.

Frequently Asked Questions

SOLIDWORKS PDM WHITEPAPER

Gain Competitive Advantage with Product Data Management

Once viewed as valuable to only design and engineering groups, product design and related data have become the essential fuel to power product development efforts. Today, all key stakeholders play a role in design collaboration, so having the right technology that enables product data to be easily found, secured, and shared is vitally important.

Read this eBook to learn how PDM software can help to:

- Improve competitiveness by sparking innovation

- Increase product quality and automation

- Protect valuable IP while enabling efficient collaboration

- Minimize rework and scrap due to tight version control

- Encourage product data reuse

- Better manage supply chains by using product data for sourcing, procurement and inventory management

Featured Customers

Petersen Inc.

A long-standing GoEngineer customer who builds some of the most impressive structures imaginable. Check out how integrating SOLIDWORKS PDM into their process has saved them time and helped them avoid costly rework.

Architectural Lighting Work

Design innovative, creative, and beautiful lighting fixtures and uses SOLIDWORKS PDM to manage all their design data as they go through the product development process.

ETS-Lindgren

Design and manufacture the electromagnetic and acoustic energy components and systems that make many aspects of modern life possible. Check out how they integrated SOLIDWORKS PDM into their workflow to improve the efficiency of their design process, as well as share engineering data throughout their organization.

Compare PDM Packages

Standard

Professional

Manage

- Manage and control your product development data with a secure file vault. SOLIDWORKS PDM manages all SOLIDWORKS file references and automatically updates them whenever you move or rename files, eliminating broken references.

- Quickly locate and reuse existing designs to save time and control costs. Instead of spending time locating prior designs on shard drives or recreating designs when you can’t find them, use SOLIDWORKS PDM tools to locate them quickly.

- Track design changes automatically and maintain a complete revision history with a standardized process that’s customized for your company’s needs.

- With SOLIDWORKS PDM your company’s sensitive and proprietary data is secure, up-to-date, and accessible with configurable security controls. User permissions can be assigned based on individuals, groups, or company role. Every change is tracked and unauthorized changes are eliminated.

- Ensure you are always working with the “right version” of a design with SOLIDWORKS PDM’s revision and version control capabilities. You can customize file naming and revision control schemes, maintain document history, and easily manage document versions to avoid the costly manufacturing errors associated with working with the wrong revision.

- Maintain a complete history of your product design, engineering, and development activities for reporting and auditing purposes.

- View eDrawings, SOLIDWORKS, and AutoCAD documents in eDrawings inside SOLIDWORKS PDM. With SOLIDWORKS PDM Professional you can view multiple other file types including MicrosoftOffice documents.

- Save time and reduce development costs through design reuse by quickly finding needed data across a range of file types using the powerful searching tools PDM offers. You can quickly perform file content searches on multiple data types (such as CAD files, Microsoft Word documents, Excel spreadsheets, Outlook emails, and images) and locate documents using a range of search criteria (including name, date, metadata, and workflow status).

- Reduce the time to complete design approvals and Engineering Change Orders (ECO). The product development process is graphically represented through an easy-to-use flowchart interface. Engineering change documentation and change approvals become completely electronic with SOLIDWORKS PDM Professional.

- Maintain, manipulate, and leverage Bill of Materials (BOM) information to support downstream applications and systems. Create individual BOM objects from existing CAD file structures that automatically update in parallel with design changes, eliminating manual updates and required when using spreadsheets. Connect your CAD data with your ERP or MRP systems, enabling you to easily update BOM information in other businesses applications. BOM information can be customized using templates to meet the needs of different users and groups.

- Facilitate compliance with government regulatory requirements and industry standards. SOLIDWORKS PDM Professional can bolster compliance for several types of regulatory requirements, including: FDA, RoHS, ISO 9001 and 14000, ANSI, and others..

- Create and maintain a single data location and vault that can be accessed by users worldwide to store and retrieve files. In addition to preserving a secure backup of product design data, secure file vaulting eliminates multiple sources of information, duplicate files, and unsynchronized revisions. SOLIDWORKS PDM Professional can be customized to meet the specific needs of your organization.

- Collaborate throughout your organization while keeping people connected, current, and working on the same set of data. Create and maintain a single data location and vault that can be accessed by users worldwide to store and retrieve files. Configure the SOLIDWORKS PDM Professional system to automatically notify users when documents have progressed through various states or stages in the electronic work flow you establish. Automatically create many types of neutral file formats from SOLIDWORKS and other file types.

- Save and share search criteria as “favorites”, providing you with instant access to common searches.

- View multiple documents in the Preview window.

- SOLIDWORKS PDM Professional provides one convenient, vaulted

location where colleagues can store and retrieve company data.

Efficient file storage and retrieval enables millions of files to be

managed effortlessly.

- Save time and effort communicating by configuring SOLIDWORKS PDM Professional to automatically create neutral file formats.

- Use serial numbers to assign automatic names to files and folders, to assign unique IDs to items, or to add unique running values to card controls. You can set up any number of serial numbers in each vault. Item Number serial numbers are defined by default to generate unique item IDs.

- Map variables to both predefined properties (such as Title and Author) and custom named properties in SOLIDWORKS files. If a SOLIDWORKS file contains configurations, the configuration names appear as tabs in the data-card. Configuration-specific values are shown in the corresponding tab.

- SOLIDWORKS PDM Professional can import variable values from an XML file into a vault database. In the vault, existing files or items that match import criteria acquire the values at specified points in the file work flow. Create an export rule to export SOLIDWORKS PDM BOM variables that can be read into ERP systems.

- SOLIDWORKS PDM Professional provides the tools and capabilities that your enterprise needs to keep people connected, up-todate, and working together, regardless of location. This global connectivity supports the distributed collaboration essential for reducing engineering development and accelerating time-tomarket.

- Enable staff and partners to contribute through web-enabled portals from various connected devices including smart phones and tablets.

- Automatically facilitate multiple required approvers with parallel transitions.

- SOLIDWORKS PDM can automatically send email notifications to alert users of changes to projects or requests for them to take actions.

- Provide critical information to help teams focus on important tasks, and provide an overview of resource capacity for better planning and utilization. Manage project stages, time lines, and milestones along with resource utilization and capacity. Utilize user tasks and time sheets to automatically track progress.

- Streamline business processes, automate document creation and bring together all involved stakeholders for new products, from sales and marketing to production and support. Configure states and decision points for all types of business processes such as Engineering Change Requests (ECR), Orders (ECO) and Notices (ECN), transmittals and approvals.

- Create, edit and compare complete bills of materials (BOM) by associating items, files and free text. Manage product variations for different use cases and applications. Drive SOLIDWORKS drawing bill of materials and item numbers directly from system data.

- Provide users with the knowledge they need to work more effectively by utilizing tasks and calendars.

- Create and distribute interactive graphical dashboards to display

critical information. Configure reports to company

Why Partner with GoEngineer?

GoEngineer is recognized worldwide as the most trusted resource in SOLIDWORKS PDM integration. Our team of Data Management specialists focuses solely on helping our customers implement SOLIDWORKS PDM into their current business environment as quickly as possible to minimize downtime and begin reaping the rewards of this powerful tool in as little as a few days.

Whereas consultants would rather build a system only they can modify, we employ a unique approach to system implementation; focused not only on configuring the simplest solution to meet your needs but training your administrators to be self-sufficient. By avoiding overly complex customizations, you gain the flexibility to adapt to needs as your company grows and evolves.

We’ve helped hundreds of businesses just like yours implement SOLIDWORKS PDM and we’re 100% confident we can help you too.

SOLIDWORKS Services:

Utilize GoEngineer’s Award Winning Support & Training for SOLIDWORKS

Award Winning Technical Support

GoEngineer's extensive SOLIDWORKS technical knowledge and world class support can help you succeed with SOLIDWORKS. Our award-winning team is ready to help you with any task you may have. Using state-of-art remote assistant technology software allows our team to solve most issues within one session. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

- 125+Certified Technical Specialists

- Email, Phone and Chat Support Available

- 98% Exceptional Customer Service Rating

PROFESSIONAL SOLIDWORKS TRAINING

GoEngineer offers online and classroom professional SOLIDWORKS training for organizations and individuals. All our instructors are SOLIDWORKS certified and teach thousands of students each year world wide. The curriculum is very diverse with numerous certified SOLIDWORKS courses to choose from. Each student will receive a Course Completion Certificate and preparation materials for SOLIDWORKS certification.

- Increase Your Earning Potential

- Led by Certified SOLIDWORKS Instructors

- Smaller Classes with Focused Attention

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services