SOLIDWORKS Plastics-Injection Mold Optimization

How does SOLIDWORKS Plastics save you money?

SOLIDWORKS Simulation has always been thought of as a useful tool to help determine things such as whether a design is going to break, withstand heat, survive a drop, or withstand certain frequencies. This helps save money by limiting the number of expensive prototypes which must be built to prove a design.

When it comes to injection molded parts, SOLIDWORKS Plastics does the same thing, as creating a bad mold that produces bad parts can be an expensive mistake. In addition, using SOLIDWORKS Plastics to help optimize plastic parts can save in not just the cost of molds, but also can help decrease your time to market.

SOLIDWORKS Plastics

SOLIDWORKS Plastics comes in two levels, Professional and Premium. Professional is meant for designers and engineers to use during the design phase, to make sure that the part they are designing is actually mold-able and to determine whether any kind of defects will occur. The Premium package allows mold designers to lay out multiple cavity molds and design runner systems, among other things.

Professional

Let’s focus on just the Professional product for engineers. Using Plastics Professional, designers can quickly determine if the part they are creating is capable of being injection molded, allowing to them to make changes on the fly before even sending out the model for mold design.

Setup

With a vast library of materials and also the molding machine options, a designer can quickly see what combinations will work. Typically the designer will know what type of material to use, and for a worst case scenario, the small molding machine can be selected. That is a 15,000 PSI machine and most molding companies will have at least that size machine and most likely even more powerful capabilities.

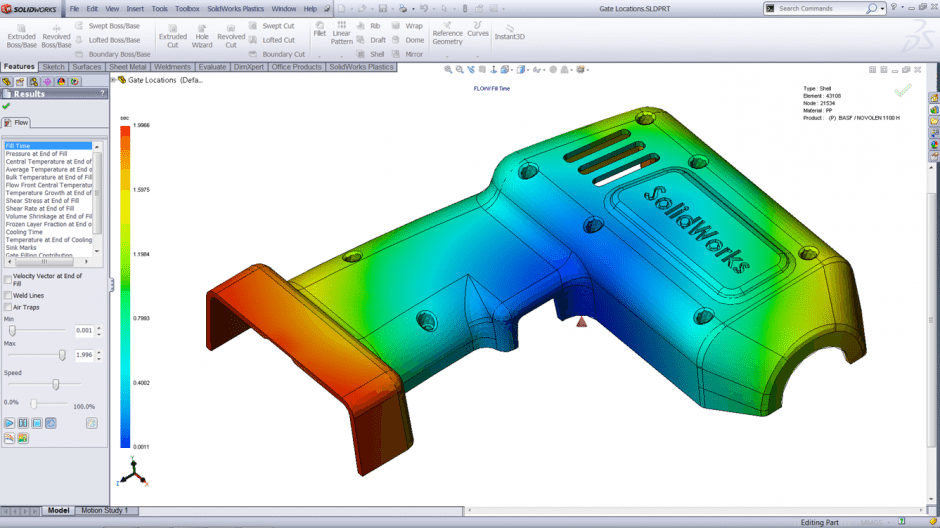

Study Results

By selecting a material type, machine size, and gate location, the designer can gather important information, including fill time (as shown below), weld lines, and air trap areas.

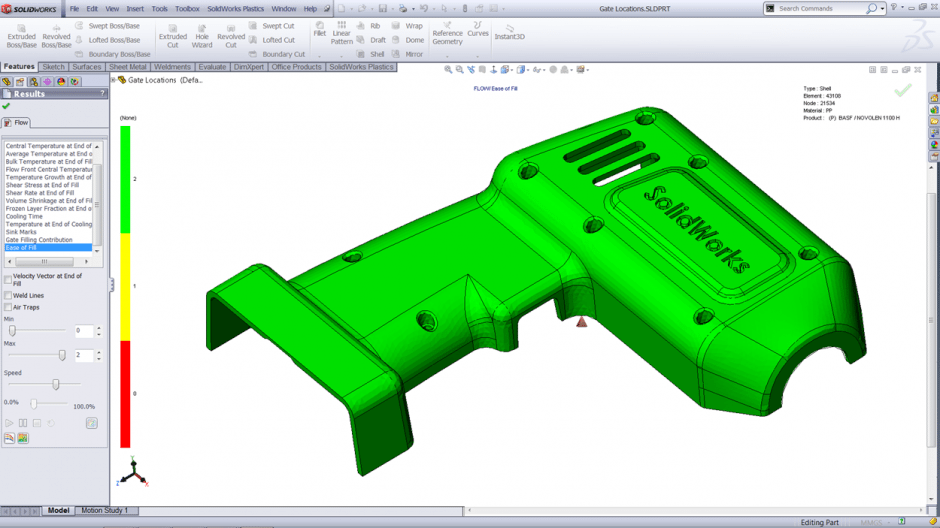

SOLIDWORKS Plastics also generates an ease of fill plot (shown below). The ease of fill plot is simple to interpret. Green is good, red is bad.

With these results the designer can get a good understanding of possible areas in the model that might be too thin or too thick to get properly molded.

Mold Optimization

The designer can use the data from SOLIDWORKS Plastics to determine optimal wall thicknesses, which can help reduce material costs and save weight. If weld lines or air traps are found in areas that can cause visual and structural defects in the model, the designer can see that and make model modifications as well. It is typically easier to modify the model early on in the process instead of finishing the design and attempting to change features, as more parent/child relationships will need to be accounted for later in the design.

The power of SOLIDWORKS Plastics can help your design get to the manufacturing process faster, decreasing your time to market so you can beat your competitors to the sale.

Want to learn more? Click Here to register for a SOLIDWORKS Plastics webinar.

Author: Joel Quizon

Blog

Blog