Beyond Dollars and Cents

This week, I decided I wanted to blog about something a little different than our typical posts. As the newest engineer on staff here at 3DVision Technologies, I’ve recognized very quickly that SOLIDWORKS and Stratasys develop and create some of the most innovative technology to meet the demands of our customers growing business. These tools provide a value towards achieving key business objectives when the vast majority of us use these tools for work. They boost our productivity. They simplify our tasks. They help keep human error out of the mix. They allow you to be who you are – a designer, an engineer, a creator and eliminate the need for you to be an expert draftsman, artist, computer wiz, etc. Close your eyes and think of that for a moment. Think about what your work would be like without these tools. Now just hold that thought, because we’re going to come back to it.

In December 2015 I joined May We Help, a non-profit organization headquartered in Cincinnati, OH dedicated to designing and building custom equipment for individuals with special needs that enable them to engage in and pursue their passions. Clients submit a project request for their specific challenge or disability and it is assigned to one of our volunteers. Our volunteers will then meet with the client to gather a better understanding of the dynamics of the issue and the design criteria for any potential solution. Afterward, it is up to the volunteer to design, source materials and parts, fabricate and test a solution before ultimately delivering it to the client.

All May We Help volunteers are either engineers, machinists or others with fabrication or manufacturing backgrounds. We carry with us centuries of cumulative industry experience, many of which at some very well-known Fortune 1000 companies. When I first saw some of the equipment we were developing, I was so impressed with the complexity and capability we had in house. Custom-built circuit boards, remote controlled chairs, a push-button fishing pole that saddles up to a wheel chair and so on. One volunteer is even actively developing glasses that follow your retina so a client can move a mouse on a computer screen! And to top it off, we have a full shop with all the equipment we might need to get a project done. I mean, I felt like I had just found the Mecca of volunteering for a mechanical engineer.

So who cares, why am I telling you all this? Well, remember that thought I asked you to keep? – What would your life be like without the tools that eliminate the need for you to be an expert draftsman, mathematician, artist, computer wiz, etc., and allow you to just be who you are – a designer, an engineer, a creator, and so on?

Well imagine that in order for you to be who you are, you required a tool to eliminate the need to be someone with just the ability to sit and hold themselves up on their own. And to be someone that has complete control and full range of motion in all their muscles. To be someone that can pedal a bike unassisted to get themselves from point A to point B. You need a tool to provide all that and more, just to be yourself.

And who you are is a 6-year-old little boy – who just wants to ride a bike.

My first project at May We Help was to modify a tricycle for an incredible 6-year-old little boy who suffers from cerebral palsy. When my partner, Paul Wenner (ret.), and I first met him, he was awesome. You could see the excitement in his eyes and when he was giving high fives and fist bumps. The tricycle was freedom for him. It was something he could do without assistance and on his own and he couldn’t wait. Paul and I went through a design review with his mother and went to work.

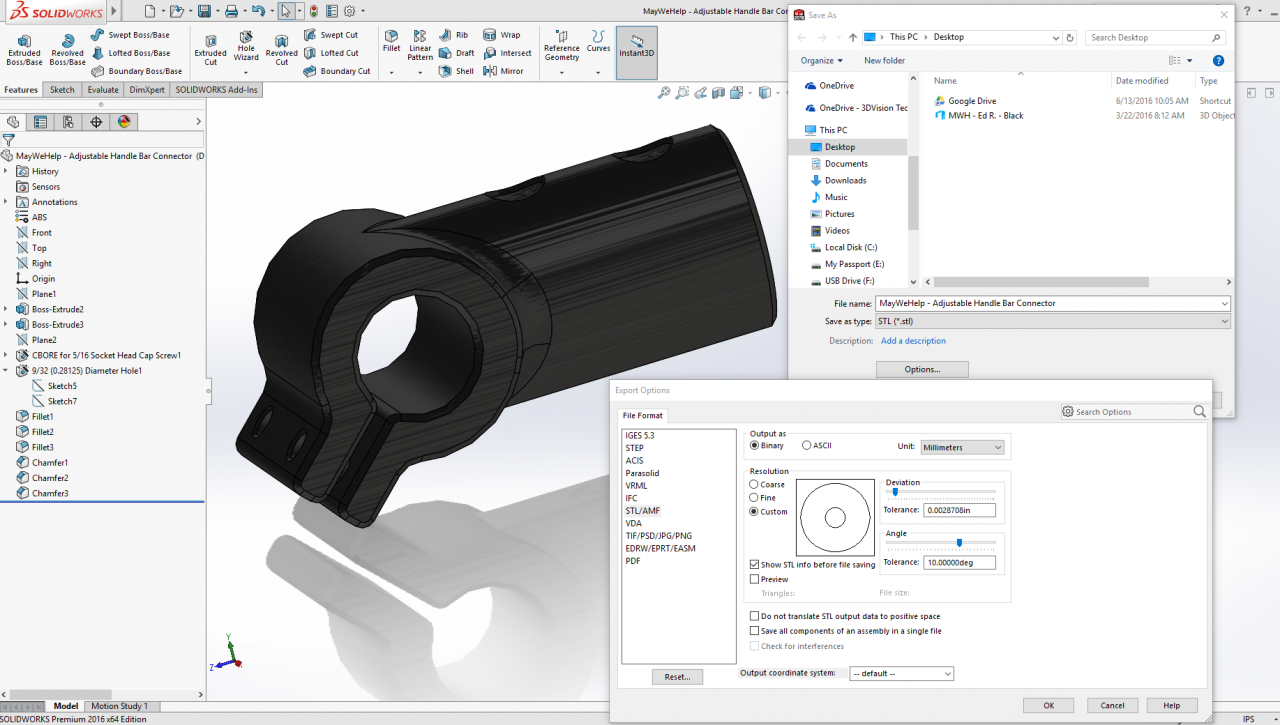

We had an existing chassis to work with, but there were many modifications to be made. We replaced the seat with something that provided more support and security. We custom built a new chain guard by welding some sheet metal. We added a detachable pole off the back so his parents could push and guide. We added a pulley system to the pedals to ensure they would stay parallel with the ground and also assist him to pedal. There was plenty more, but the biggest challenge we had were the handlebars. We had to build this tricycle so that it would adjust as he grew, knowing he could have it for at least 10 years or more. This presented a challenge, how to design the handlebars so that they could adjust over time. We went through multiple iterations and a lot of coffee before we realized we would have to weld something up or 3D print the parts. We needed two of whatever it was, and 3D printing ensured us they would both be the same (I am not an expert welder – I know for a fact I would have to do it 5 times to get it right!). So off to SOLIDWORKS I went to draw up my part (below).

Simple I know!

Thankfully the 3DVision team supported me on this and I am so grateful to them for that. So I adjusted the settings when exporting it to a STL file to just make it a bit more solid and have a higher density. You can view that above. It is done just through the “Save As” dialog when you select “Options” for an STL. They allowed me to print my parts in ABS black and they worked perfect after I reamed the shaft hole (because I didn’t account for any shaft clearance. Insert Homer Simpson “D’oh” here). Now we had the handlebars we needed with the ability to adjust for his size over time.

Now all the parts were complete and we just had to paint it. After stripping, sanding, 2 coats of primer, sanding, 3-4 coats of paint and 2 coats of clear coat, the tricycle turned out like this:

Finally, we were able to deliver the tricycle to this young man and in all seriousness, I can honestly say there has never been a more humbling and gratifying experience in my lifetime. I will hold this memory in the front of my mind always to remind me to have humility and appreciate everything I should be grateful for. When I witnessed the light beam from that little boy’s face I saw that despite everything he goes through on a daily basis in his life, the challenges he faces each and every day to do the things I take for granted like walking unassisted, talking without sign language, clothing myself, feeding myself, etc. this little boy was just so happy and grateful to ride his bike. None of his challenges or disabilities were relevant to him. They weren’t important. I knew then that he had just given me a gift that was so much more valuable than anything I ever gave him, humility and a lesson on how to live happy.

While we may not often think about it, the value of SOLIDWORKS and Stratsys technology is not always just for a world of dollars and cents. Their value can also be as simple as providing individuals like this young man a more productive and simplified means to be who he is – a boy who wants to ride his bike.

If you are interested in volunteering at May We Help, or you or someone you know has a project they would like to submit, please check out the website and contact information below. We have facilities in both Cincinnati and Columbus OH. We are ALWAYS looking for more help and more projects!

7501 Wooster Pike

Cincinnati, Ohio 45227

(513) 340-8102

Blog

Blog