What I Learned During my CATI Internship

My summer internship with CATI took place in their Buffalo Grove, Illinois office. It was undoubtedly comprised of some of the most influential months in my professional development thus far. Between CAD, 3D scanning, and 3D printing I experienced much of what CATI offers.

Over the course of my internship, I was able to take advantage of many of the SOLIDWORKS training classes offered through CATI. A combination of in-person and online courses prepared me to achieve both my CSWA and CSWP certifications. These certifications are not only a source of pride, but prove I have valuable CAD skills I can take into my future employment opportunities.

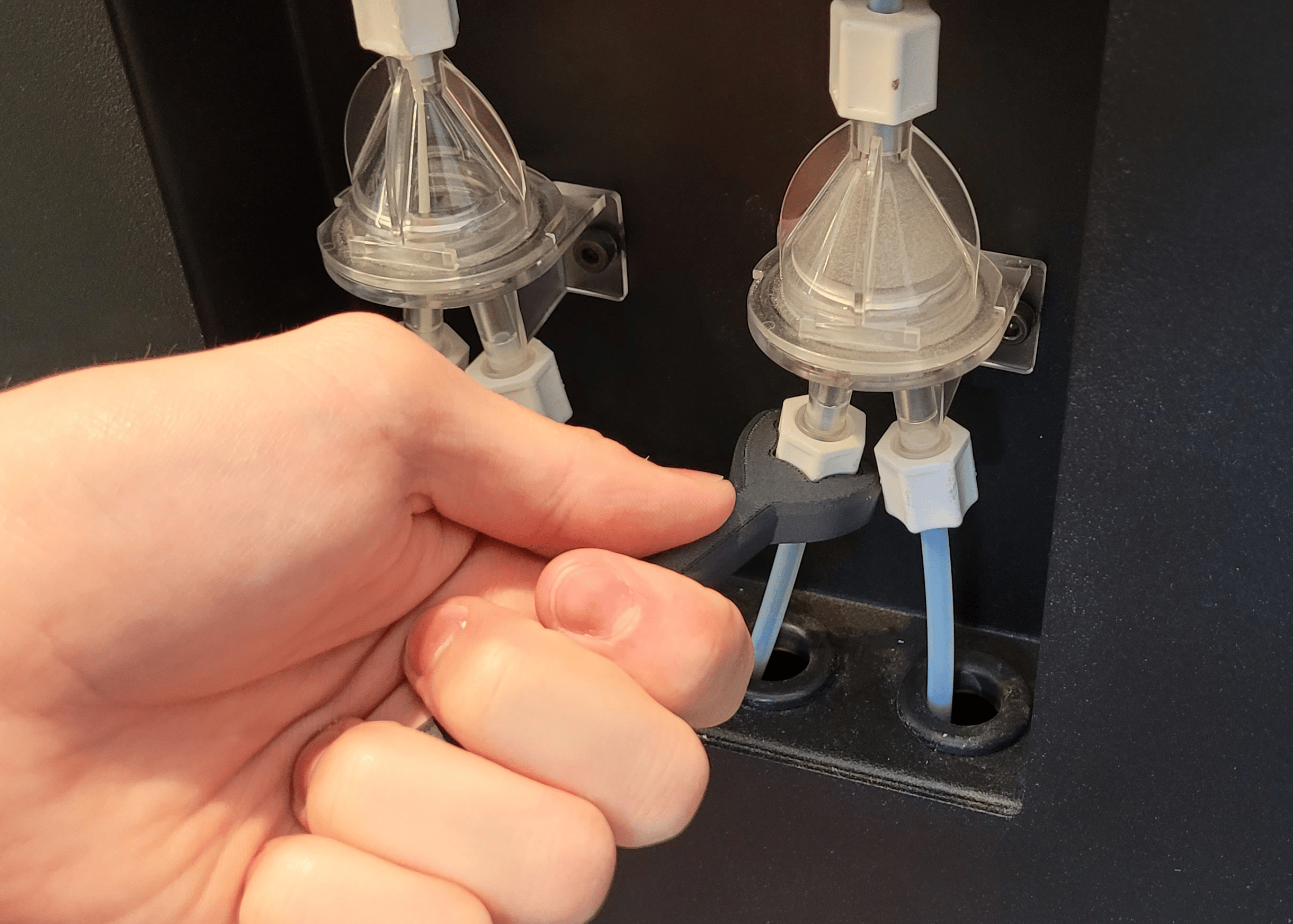

A custom Y-block wrench makes it easy to remove tight fittings on the Stratasys F370.

My Role

My role with CATI primarily revolved around the hardware side of the business – working with 3D printers and 3D scanners. From printer repair tools to custom-printed room placards, to organizational tools, I printed a lot this summer. The tools I designed and printed included a lockout key for an Objet printer, a Y-block wrench for the Stratasys F123 series printer, and a belt tensioning tool. These tools were printed using FDM technology with a Stratasys F370. Each of these tools taught me a different lesson about designing for 3D printing, such as the impact of slice height on surface finish and part strength or how tolerances can affect the fitment of moving parts.

One of the many custom room placards printed using the J55 Polyjet printer.

The Fun Stuff

More decorative parts such as employee name plates were printed using PolyJet technology on either the Stratasys J55 or J850. This technology can create parts with impressive colors, textures, and finishes, making it an excellent choice for design visualization. For example, the custom room placards I printed needed to contain the correct Pantone colors used in the CATI logo. This took some research and experimentation to get right but produced parts with highly accurate color recreation. These projects taught me more about the post-processing required to achieve a desired finish and texture using PolyJet printers.

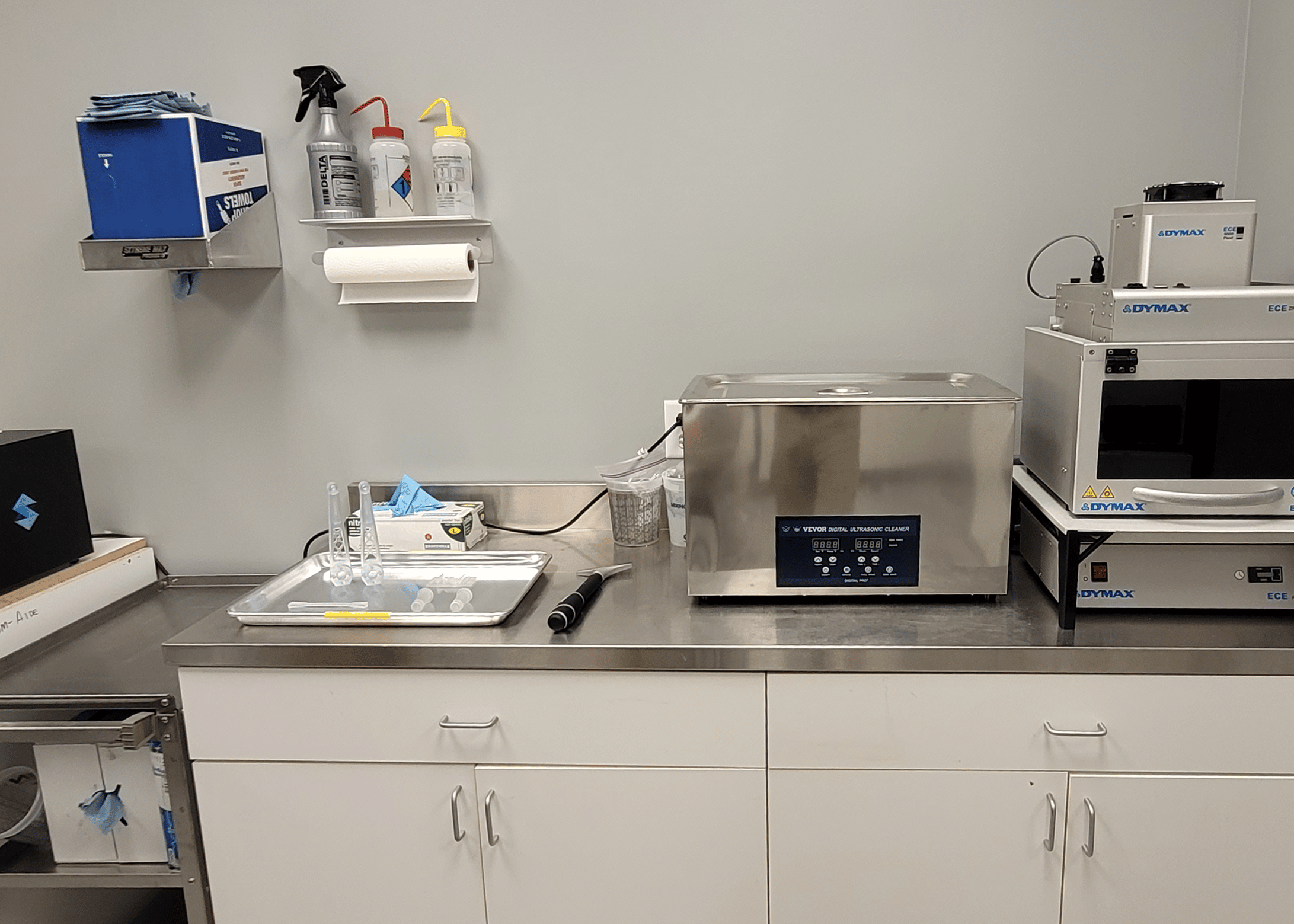

This workstation was designed to accommodate the various tasks required to post-process Origin One parts.

Everything Else (More Fun Stuff)

Outside of these projects, I also worked a lot with the new Stratasys Origin One printer. I learned a lot about the new materials available with this printing system, some of which have incredible properties with regards to heat deflection. It was interesting working with my colleagues to develop procedures for working with an unfamiliar group of resin 3D printing materials. This provided me with opportunities to practice problem solving and workflow optimization in cooperation with a team.

I participated in a few scanning services, both on-site and in the office. Through these services I learned how different companies use 3D scanning for reverse engineering and quality inspection. During an on-site scanning service, I learned about how the scanning workflow changes to accommodate larger subjects – in this case, the axle of a bulldozer and an entire bucket attachment. I was able to apply this experience on a reverse engineering project where I scanned, reverse engineered, and designed clip-on project labels for our standardized project tray system.

During my time with CATI, I developed a lot of practical and hands-on engineering skills that are often overlooked in a college education. An example of this is the importance of rapid revisions. Many of my projects went through many iterations, and I learned from each one and improved the project as a result. The knowledge and experience I was able to obtain over the course of the summer was beneficial in preparing me for an engineering job in a way that cannot be taught in a classroom.

Aaron Fanjoy

Engineering Services Intern

Computer Aided Technology

Blog

Blog