Print Large Parts

Print Large Parts

Print large parts from you’re 3D Printers! That is to say, print sections of your large parts and assemble them together after the fact. If you have investigated 3D printers recently you will notice a pretty direct correlation between price and the build chamber size of the machine. Stratasys machines are no exception with the cheapest commercial grade printer by Stratasys having a 5”X5”X5” build chamber. The largest of the Stratasys printers has a 3ftX2ftX3ft build chamber, and a price to match.

Now it usually comes down to the decision of which size printer to get. We usually recommend a printer the can fit about 80% of your usual parts that needs to be made. The last 20% of parts really ups the price point of the machines and is hard to justify.

So now that we settled on a machine that can handle most of what we do we just need to figure out what to do with the occasional large part that needs to be made. There are several ways to approach splitting your parts up and joining them together later.

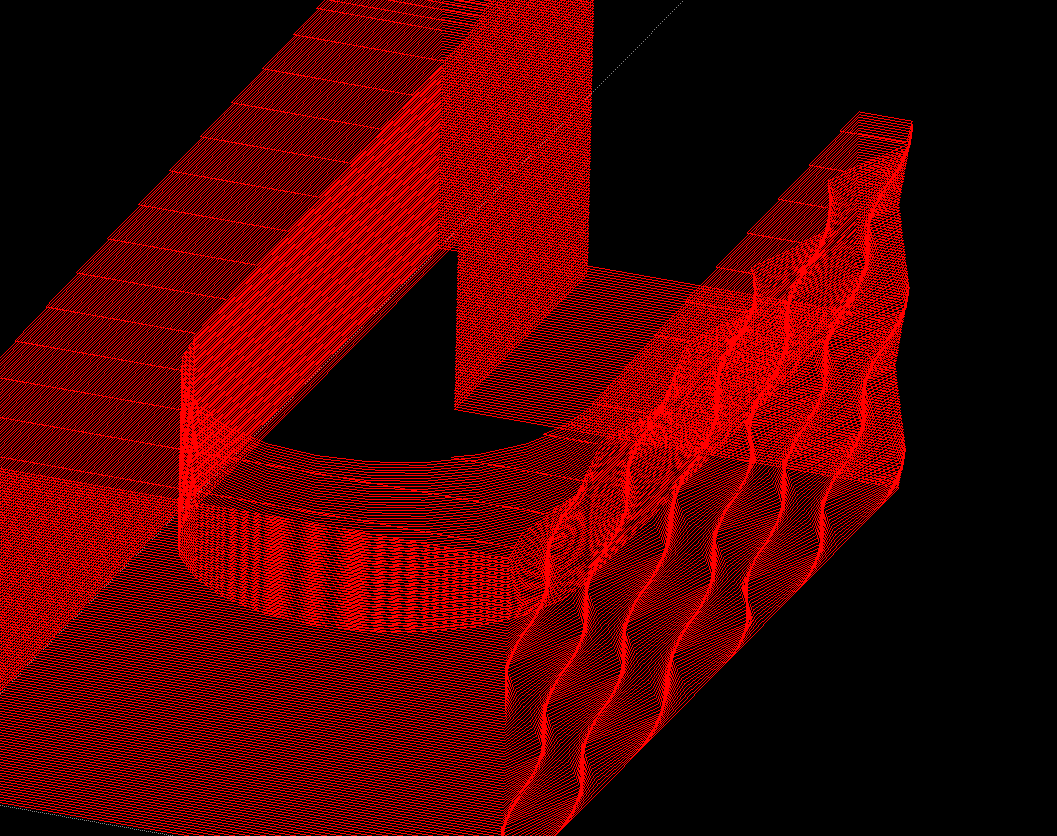

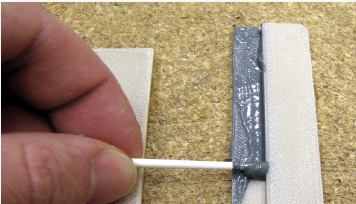

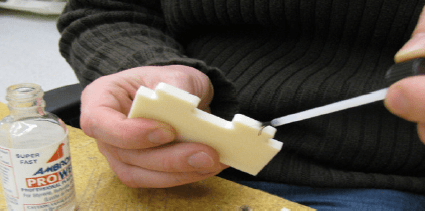

One option is to just send the larger parts out to be printed by service company. A cheaper option is to split your parts up in your CAD program that you modeled it in or split it with the printer software. This is going to involve cutting the part in specific areas to join together later. Thing to look out for when doing this places that could hid the connection so it is not obvious, areas that are strong and thick enough to accommodate a connection point, and also adding various registration features to help with aligning the parts correctly. The registration features can take many forms, from a simple tongue and groove, pins and corresponding holes to fit into, and more complex sawtooth patterns. Depending on your geometry one might be easier than another to join together.

The Stratasys FDM insight software has built in features for splitting parts with added registration features automatically for easily splitting and printing large geometries.

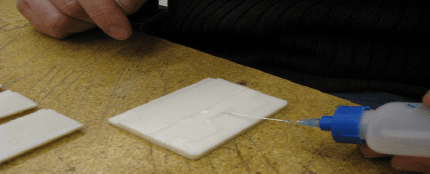

Also depending on the material you are using there are different bonding methods to connect the parts together. The general go to for most plastic parts would be a simple ‘super glue’ (cyanoacrylate).

If you want a stronger bond you can upgrade to using a 2-part epoxy. This results in a stronger bond but can also start to add more glue thickness to the joint. This would be something that might need to be taken into consideration if you need to have a gap to allow for the epoxy.

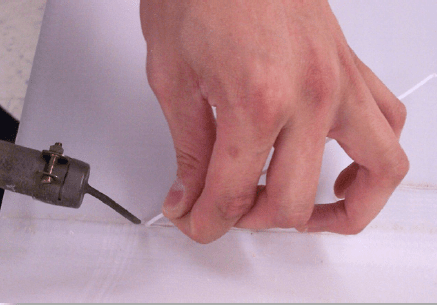

With a lot of the thermoplastics there are a few more options that can be used. All of theses can be fused together with ‘hot air welding’ to melt some filament in-between the two parts, this is a strong connection but does not penetrate very deep.

Another option would be to use a solvent bond to melt the joints together. This is heavily dependent on the type of plastic for what kind of solvent will work on it.

Tim Crennen

Applications Engineer, 3D Printing and 3D Scanning

Blog

Blog