Want to Print a Metal Part? Why Not Start with Plastic!?

There has been a lot of hype surrounding the use of metal 3D printers over the last few years. With GE’s recent aquisitions of metal printer manufacturers and investment into metal printing, this hype has accelerated. Questions around metal printing come up all the time at trade shows. I’m sure Stratasys will be a player in metal printing eventually, but we’re not there yet. For the moment, we have a wide assortment of thermoplastics and thermoset resins at our disposal.

DMLS (Direct Metal Laser Sintering) is good for very complex metal parts, parts that couldn’t be machined traditionally, but you’ll really need a compelling ROI to justify its use. Recently I hosted a webinar where we dove into all the requirements, processes, and on going expense to operate and maintain metal 3D printer (see link at the end of this blog post).

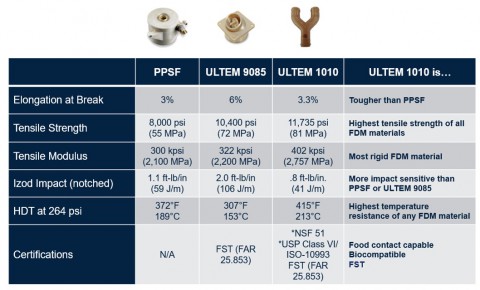

This past summer, I was involved in a training webinar where I learned of a process that may bridge the gap between metal printing and our current thermoplastics. See below for a screenshot of our Ultem 9085 material specs for reference.

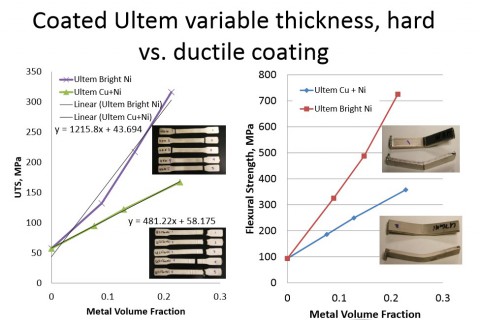

Our Ultem 9085 was tested to 10,400 PSI. This is incredible for a thermoplastic! But what if you needed something just a little higher for your application? In the past I would have recommended a traditionally machined part because there was no way we could touch those requirements. Today we’ll discuss plating. You can plate almost anything that can be made conductive. Below is a new tensile strength test with Nickel plated Ultem 9085. Pay close attention to that Purple line, following that across we see our new tensile strength is slighly over 300 MPa or 43,500 psi!

Plating isn’t just used for increased strength, it can be used for many new and increased properties including EMI Shielding, Cosmetics, Head Conduction or HDT, abrasion resistance, and conductivity (just to name a few).

Do you have an application that could benefit from this new process? Let us know! We’d love to work with you.

Blog

Blog