The Best of 2018: A Fisher Unitech Recap

Happy new year! 2019 is upon us and as we ring in the new year, let’s reflect on the old. Last year was significant for Fisher Unitech, its partners, customers, and staff. 2018 saw significant investment throughout our organization, including a move to our new state-of-the-art Headquarters (which was named one of Michigan’s best places to work). It saw technological advancements in hardware and software from our longtime partners Stratasys, SOLIDWORKS, and Artec (as well as some exciting new partnerships) that will help our customers continue to lead the world in manufacturing innovations. I’d take a few moments to recognize some of our shared achievements of 2018.

Happy new year! 2019 is upon us and as we ring in the new year, let’s reflect on the old. Last year was significant for Fisher Unitech, its partners, customers, and staff. 2018 saw significant investment throughout our organization, including a move to our new state-of-the-art Headquarters (which was named one of Michigan’s best places to work). It saw technological advancements in hardware and software from our longtime partners Stratasys, SOLIDWORKS, and Artec (as well as some exciting new partnerships) that will help our customers continue to lead the world in manufacturing innovations. I’d take a few moments to recognize some of our shared achievements of 2018.

Partnering

2018 was a strong year for Stratasys, expanding its FDM material portfolio to include PEKK and TPU. Improving PolyJet color and texture reproduction with Vivid Vero materials, the J750 has become invaluable in consumer goods prototyping, as well as surgical planning. Also, composites printing came within reach of even more customers with the introduction of the Fortus380CF. GrabCAD Print announced the first parametric CAD optimization tool for FDM, with its ‘Advanced FDM’ Add-in.

2018 was a strong year for Stratasys, expanding its FDM material portfolio to include PEKK and TPU. Improving PolyJet color and texture reproduction with Vivid Vero materials, the J750 has become invaluable in consumer goods prototyping, as well as surgical planning. Also, composites printing came within reach of even more customers with the introduction of the Fortus380CF. GrabCAD Print announced the first parametric CAD optimization tool for FDM, with its ‘Advanced FDM’ Add-in.

Meanwhile, SOLIDWORKS continues to adapt to the 4th industrial revolution, improving its Mesh Editing tools, Topology Optimization, and native 3D printing support. This, on top of the improvements to SOLIDWORKS PCB, Visualize, and other core components help continue to keep SOLIDWORKS at the head of the pack.

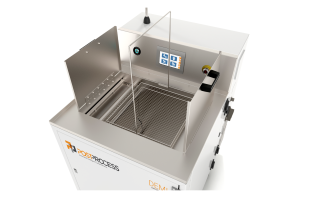

Back in May, we announced our partnership with PostProcess Technologies, the pioneer of post-printing solutions for industrial 3D printing. The Base, now installed in our HQ office, offers automated ‘dry parts in; dry parts out’ support cleaning functionality for parts up to 3ft long! Our Rador media finishing station saves hours of manual hand-sanding to get smooth-finished parts. The PostProcess platform aligns perfectly with our mission; their combination of software, chemistry, and hardware solutions will allow our customers to significantly improve their operational efficiency and quality.

Back in May, we announced our partnership with PostProcess Technologies, the pioneer of post-printing solutions for industrial 3D printing. The Base, now installed in our HQ office, offers automated ‘dry parts in; dry parts out’ support cleaning functionality for parts up to 3ft long! Our Rador media finishing station saves hours of manual hand-sanding to get smooth-finished parts. The PostProcess platform aligns perfectly with our mission; their combination of software, chemistry, and hardware solutions will allow our customers to significantly improve their operational efficiency and quality.

August marked the beginning of our partnership with Nano Dimension. The Dragonfly 2020 PCB printer complements our Stratasys printers and SOLIDWORKS PCB design software, enabling our customers to drastically shrink the development cycle by 3D printing functional printed circuit boards.

In November we welcomed the Desktop Metal Studio System, the first 3D metal printer that is safe, cost-effective, and easy-to-use in the office. We announced our Fisher Unitech and Desktop Metal partnership back in August 2017 and we were excited to be the first to receive a complete Studio System (Printer, Debinder, and Sintering Furnace) We have been churning out metal parts ever since and look forward to seeing what this transformative technology will do for our customers.

In November we welcomed the Desktop Metal Studio System, the first 3D metal printer that is safe, cost-effective, and easy-to-use in the office. We announced our Fisher Unitech and Desktop Metal partnership back in August 2017 and we were excited to be the first to receive a complete Studio System (Printer, Debinder, and Sintering Furnace) We have been churning out metal parts ever since and look forward to seeing what this transformative technology will do for our customers.

Innovating

Leading automotive industry leader, Ford Motor Company, opened a brand new $45 million Advanced Manufacturing Center in Redford, Michigan. With the use of 3D printers, virtual reality, and state of the art robotics, Ford Motor Company is able to bring manufacturing to a whole new level. We are proud to have Ford as our partner, and we’re thrilled to be able to assist them with their 3D printing needs for the development of this new manufacturing center.

One of the most highly anticipated announcements in 2018 was the relocation of two of our offices. Our Eastern Pennsylvania office moved to Ambler Yards in Ambler, PA. The larger facility and showroom accommodates more machines and host events.

In 2017, The Fisher Unitech headquarters began a move from Troy to Pleasant Ridge, Michigan. In September 2018 we moved into our state-of-the-art new facility. The new space features a large manufacturing showroom complete with training facilities and over a dozen professional 3D printers. The extra space (and larger doors) enables us to showcase the entire Stratasys lineup, including the F900 and J750 (to name a few), the Desktop Metal Studio System, Nano Dimension Dragonfly 2020, and PostProcess Technologies Base and DECI. If you’re in the area, I hope you’ll drop by for a tour.

Growing

It is our mission to fundamentally advance manufacturing in America. We want our customers to be the best, and that means providing them with the very best technical expertise in the industry. In February, we were honored to accept several elite awards for superior customer service, support, and sales achievements. To this end, we’ve continued to grow not only our technical staff but individual departments as well. In 2018 we increased our Headquarters count by 20% and forecast another increase of 15% by the end of 2019.

It is our mission to fundamentally advance manufacturing in America. We want our customers to be the best, and that means providing them with the very best technical expertise in the industry. In February, we were honored to accept several elite awards for superior customer service, support, and sales achievements. To this end, we’ve continued to grow not only our technical staff but individual departments as well. In 2018 we increased our Headquarters count by 20% and forecast another increase of 15% by the end of 2019.

But excellence starts at home, with a continued commitment to enriching the employee experience and company culture. And so, we were honored to be named one of Metro Detroit’s 2018 Best & Brightest Companies to Work For. I look forward to kicking off 2019 with all of you, and I wish you a healthy start to the new year.

To continue learning about the latest industry news and tips to optimize your investments, subscribe to our newsletter and blog. Happy new year to you and your family.

–Matt Wise, CEO

Blog

Blog