Flow Simulation Header Transient Analysis

In the previous blog “Flow Simulation and the 75 Dollar Question” the differences between a stock, aftermarket short tube, and aftermarket long tube header were analyzed. Flow Simulation was utilized to compare the headers and decide whether or not the long tube header was worth the extra 75 dollars. The criteria used to evaluate the headers was total pressure drop. A constant flow into all four runs and a pressure outlet was used to evaluate the over all pressure difference. This may not be a fully accurate analysis of the real flow pattern however the generalization of a constant flow sped up the analysis time. For all of you who inquired about pulsed flow, the answer is yes we can handle that.

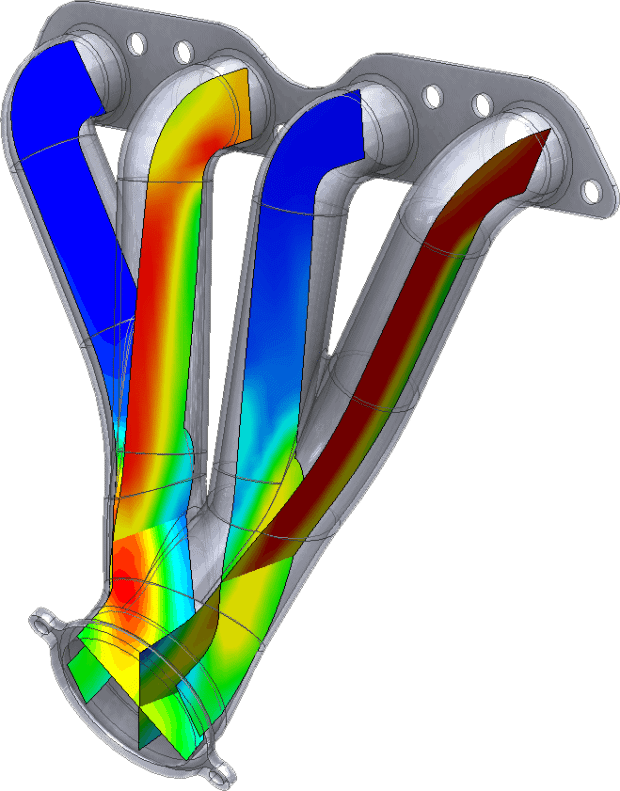

This blog shows the setup and results of the pulsed flow analysis on the short tube header.

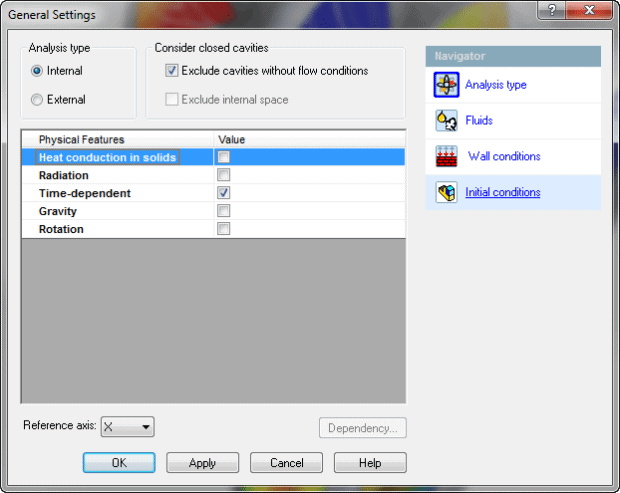

The main difference in the studies is the “time” dependency. When specifying the Flow Study in the wizard check the “time’ option.

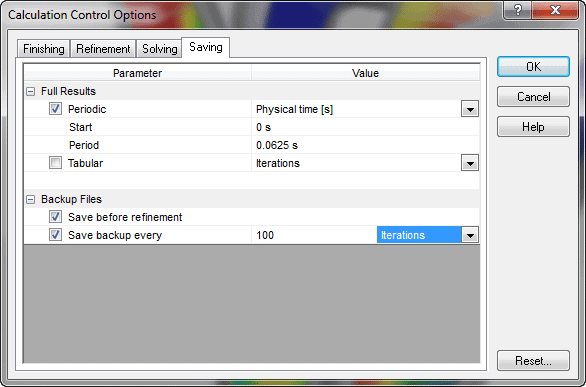

The overall time and time interval (period) needs to be specified within the wizard. This can be changed through the calculation control options as well.

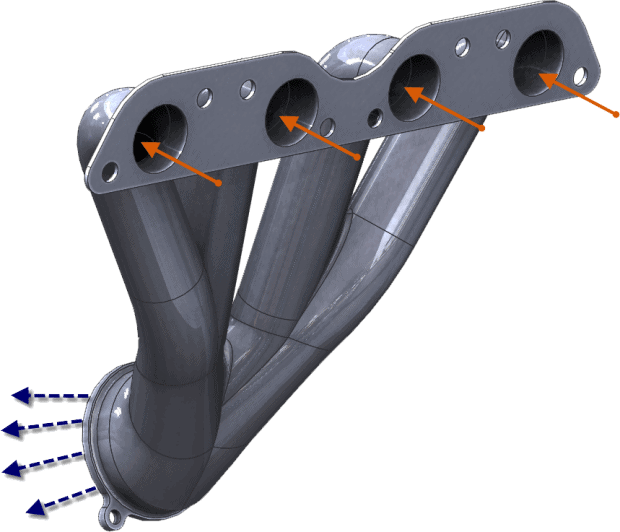

The header has in inlet and outlet as shown below.

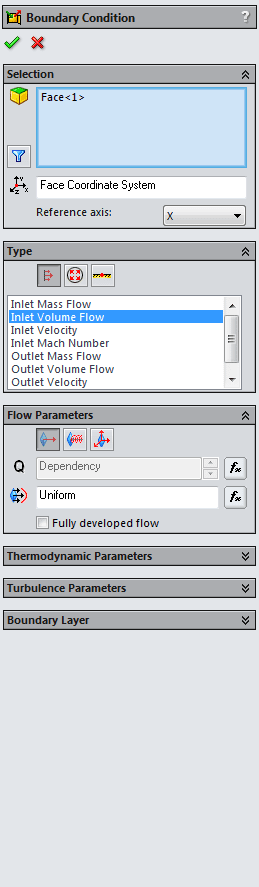

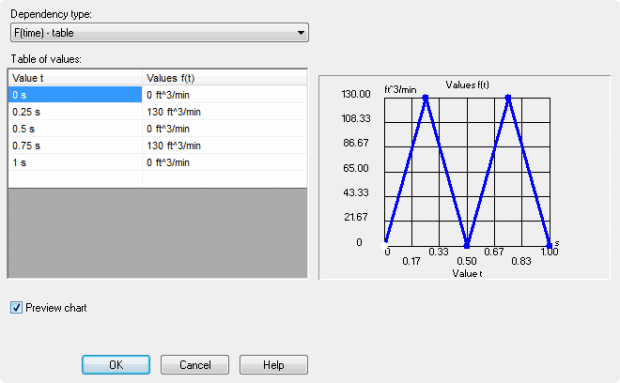

To apply a pulsed flow per inlet into the header the inlet boundary conditions need to vary with time. By selecting the dependency button in the property manager of the boundary condition. This allows the user to vary the flow with time. For cylinders 1 and 3 the dependency looks like below.

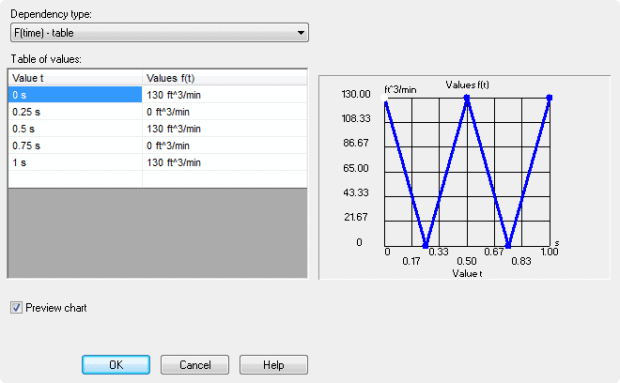

For cylinders 2 and 4 the dependency is out of phase with cylinders 1 and 3. Below is the curve.

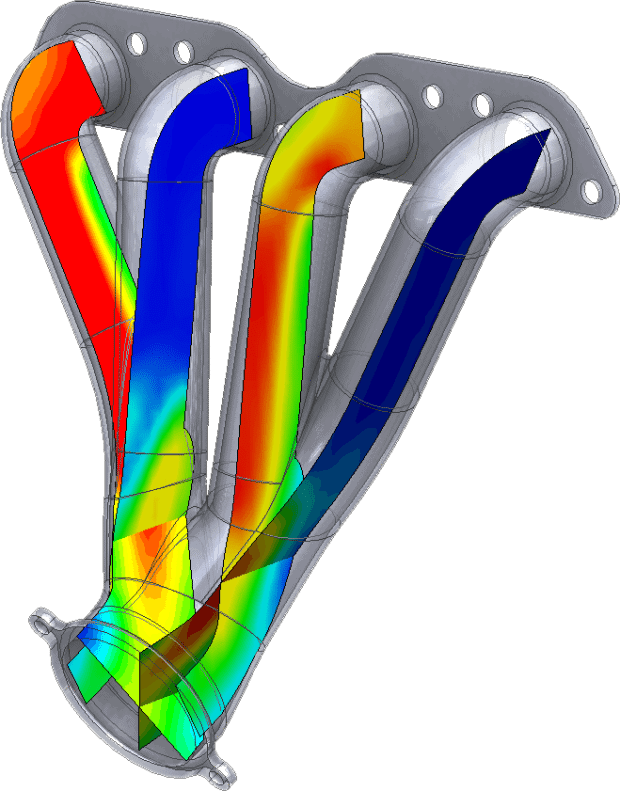

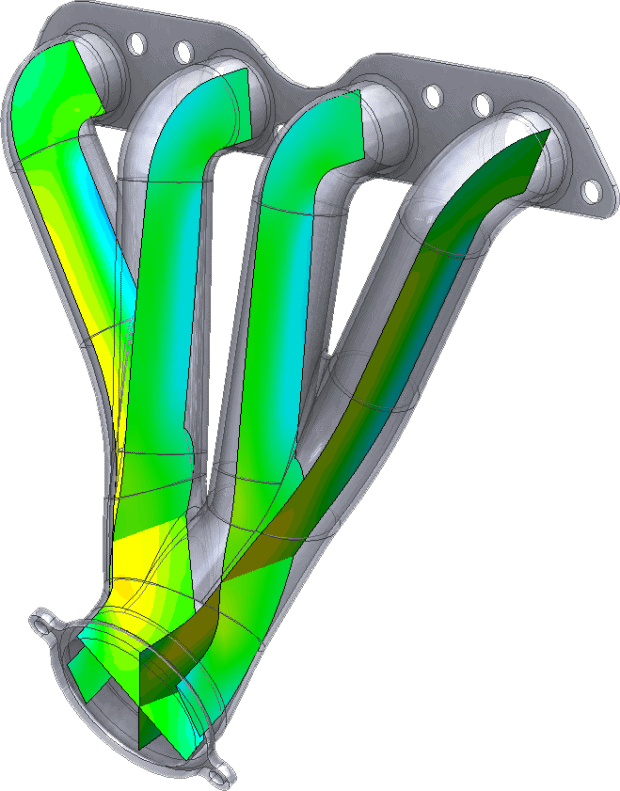

As the study runs the live preview will show the pulsed flow. The results below are at 0.25 Seconds, 0.375 Seconds, and 0.5 Seconds respectively.

Flow Simulation can also generate an .avi file from the independent time steps.

[youtube]http://youtu.be/ta8JryGOHLg[/youtube]

Based on the generalized constant flow model of the previous blog “Flow Simulation and the 75 Dollar Question” it was understood that the long tube header was not worth the extra cost. In this blog the question of transient pulsed flow was addressed and demonstrated. Obviously the frequency of the pulsed flow varies with engine RPM, and can be accounted for by generating a boundary condition curve that reflects the period and shift of increasing or decreasing the engines speed. In this blog a fixed period was used to demonstrate the ability of the pulsed flow. Flow Simulation offers an abundance of tools to help make better decisions, receive answers faster, and smarter insight into flow challenges.

Blog

Blog