What can Stratasys ABS plastics do for you?

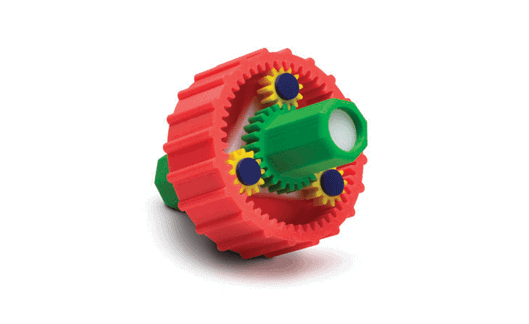

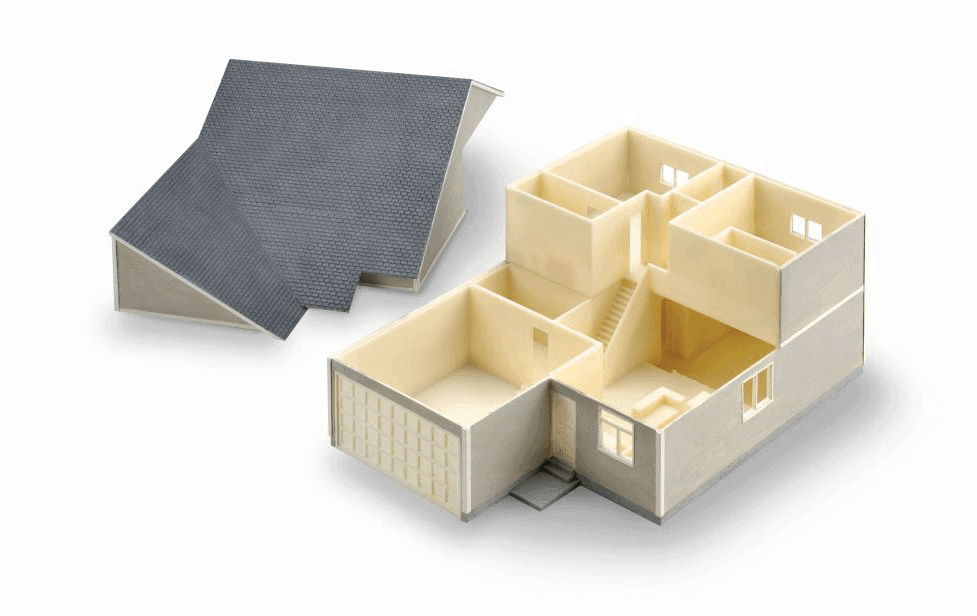

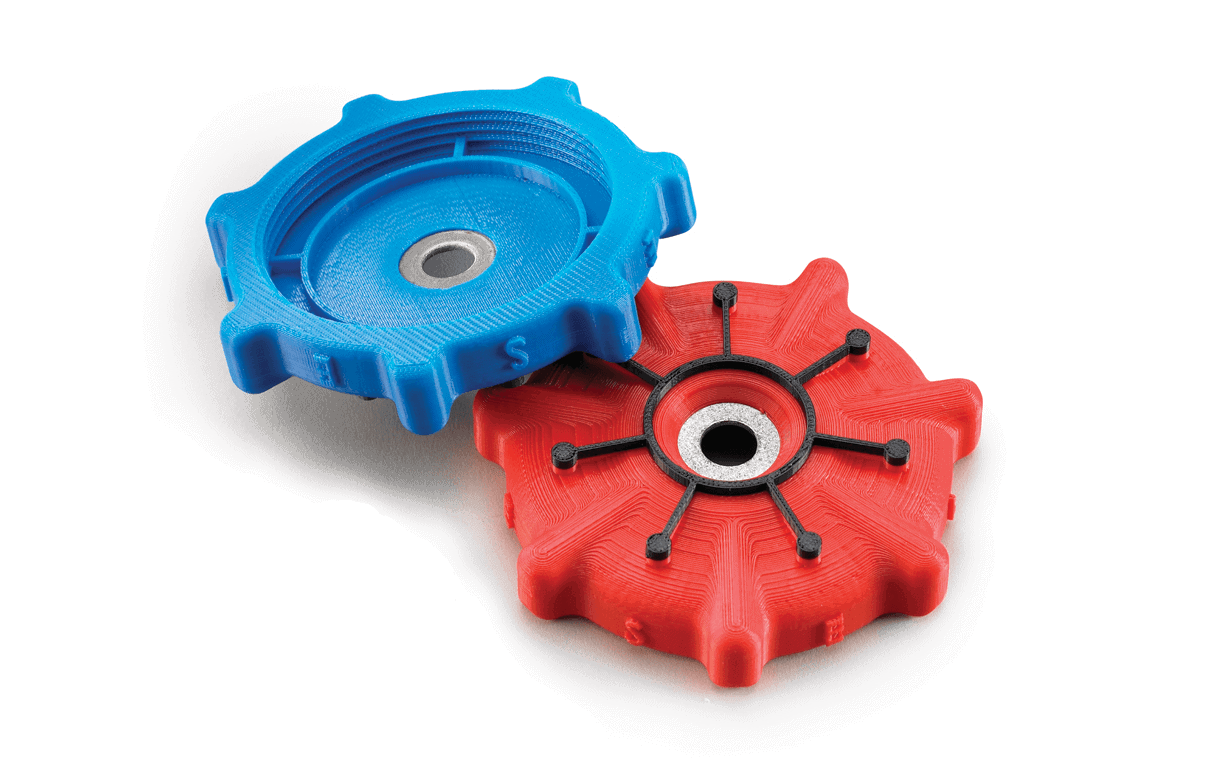

Acrylonitrile Butadiene Styrene (ABS) is an opaque thermoplastic and amorphous polymer. “Thermoplastic” (as opposed to “thermoset”) has to do with the way the material responds to heat. Thermoplastics become liquid (i.e. have a “glass transition”) at a certain temperature (221 degrees Fahrenheit in the case of ABS plastic). They can be heated to their melting point, cooled, and re-heated again without significant degradation. Instead of burning, thermoplastics like ABS liquefy which allows them to be easily injection molded and then subsequently recycled. ABS is also an amorphous material meaning that it does not exhibit the ordered characteristics of crystalline solids.

Stratasys offers five different types of ABS plastic for FDM printers. ABSplus, ABS-M30, ABSi, ABSM30i, ABS-ESD7. The plastic is in filament form and availability varies by printer type.

ABSplus is available in nine colors using production-grade thermoplastics. Designing can be iterative with ABSplus‘ affordability and color range. With hands-free soluble support removal you can do more for less while printing strong, stable parts. ABSplus plastic has tensile strength, yield 31 MPa, tensile modulus 2,200 MPa, HDT @ 66 PSI 96 °C, Impact toughness IZOD Impact, notched (Method A, 23 C) – 106 J/m. Download the data sheet and safety data sheets here:

View the ABSPlus Material Spec Sheet.

View the ABSPlus Material Safety Data Sheets

ABS-M30 is 25 to 70 percent stronger than standard ABS, making it ideal for concept modeling, functional prototyping, manufacturing tools and end use parts. With significantly stronger layer bonding than ABS and greater tensile, impact and flexural strength, ABS-M30 parts are stronger, smoother and have better feature detail. ABS -M30 has a tensile strength yield 31 MPa (XZ Axis), 26 MPa (ZX Axis), tensile modulus 2,180 MPa, heat deflection temp @ 66 psi, 0.125″ unannealed – 96 C, Impact Toughness IZOD Impact, notched – 2.4 ft-lb/n (XZ Axis), 128 J/m (XZ Axis). Download the data sheet and safety sheest here:

View the ABS-M30 Material Spec Sheet.

View the ABS-M30 Material Safety Data Sheets

ABSi is a high strength, see-through material useful for concept models and functional prototypes requiring translucency, such as those used in automotive, aerospace, and medical devices. Tensile strength yield 37 MPa, tensile modulus 1,920 MPa, heat deflection temp @266 psi 86°C Impact Toughness IZOD Impact, notched (Method A, 23 C) – 96.4 J/m. Download the data sheet and safety sheets here:

View the ABSi Material Spec Sheet.

View the ABSI Material Safety Data Sheets

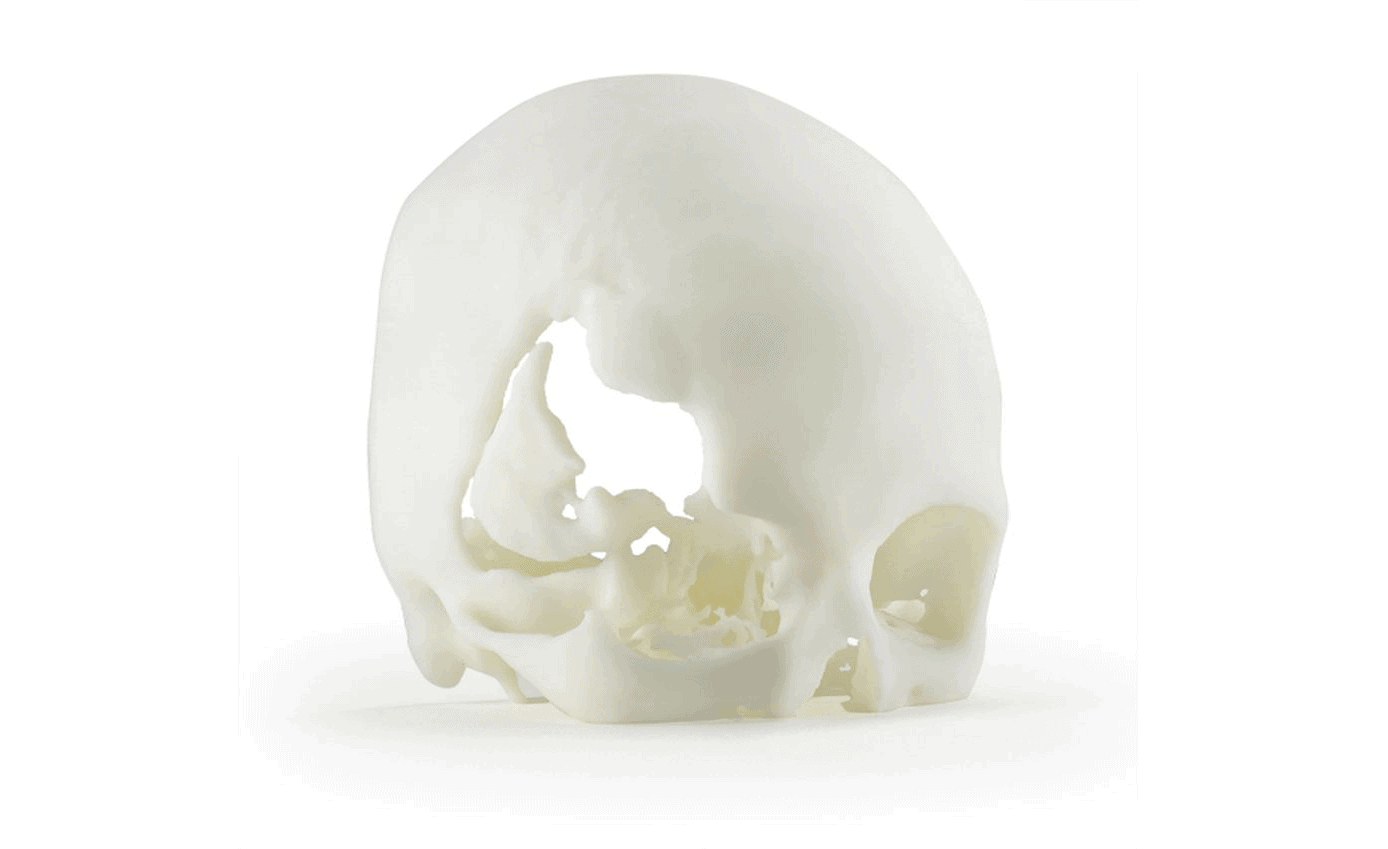

ABS-M30i is a biocompatible 3D printing material perfectly suited for medical, pharmaceutical and food-packaging engineers and designers to produce surgical planning models, tools and fixtures. ABS-M30i is a bio-compatible material that can be gamma or EtO sterilized and complies with ISO 10993 and USP Class VI. This material can be used for products that come in contact with skin, food and medications. Tensile strength 31 MPa (XZ Axis), 26 MPa (ZX Axis), Tensile modulus 2,180 MPa, HDT @ 66 PSI 96 °C, Impact Toughness IZOD Impact, notched – 2.4 ft-lb/n (XZ Axis), 128 J/m (ZX Axis). Download the data sheet and safety sheets here:

View the ABS-M30i Material Spec Sheet.

View the ABS-M30i Material Safety Data Sheets

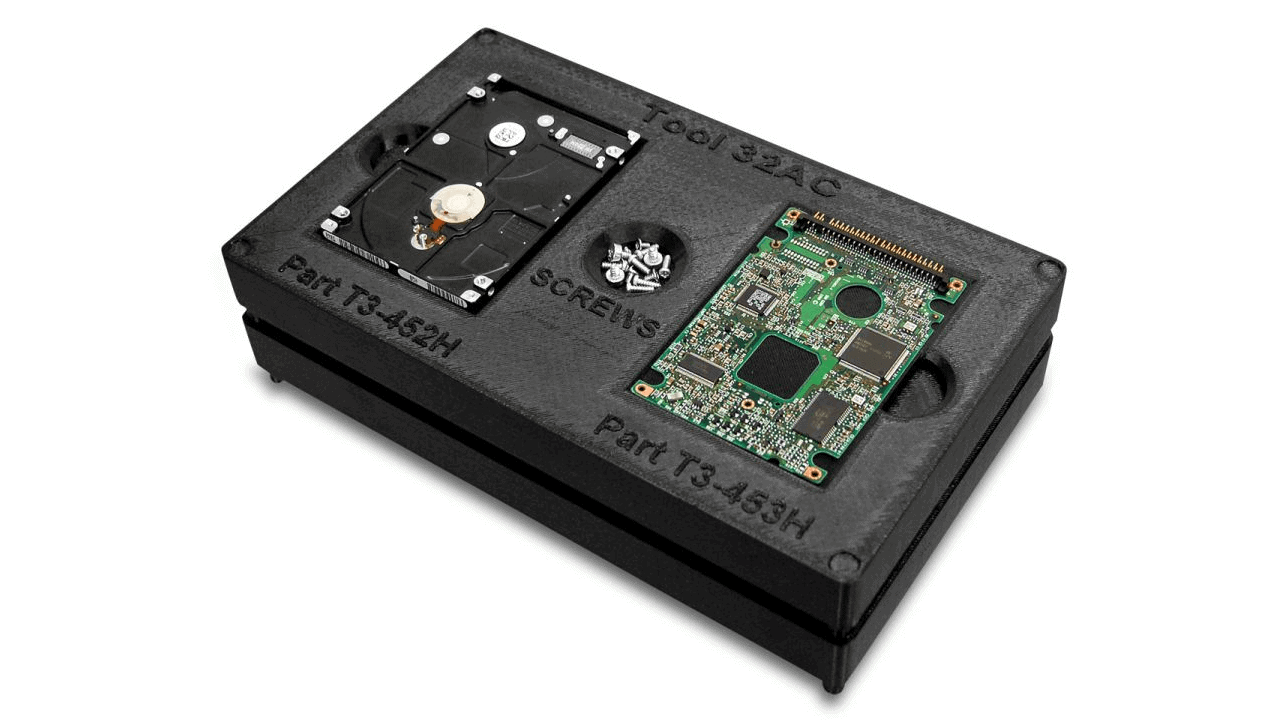

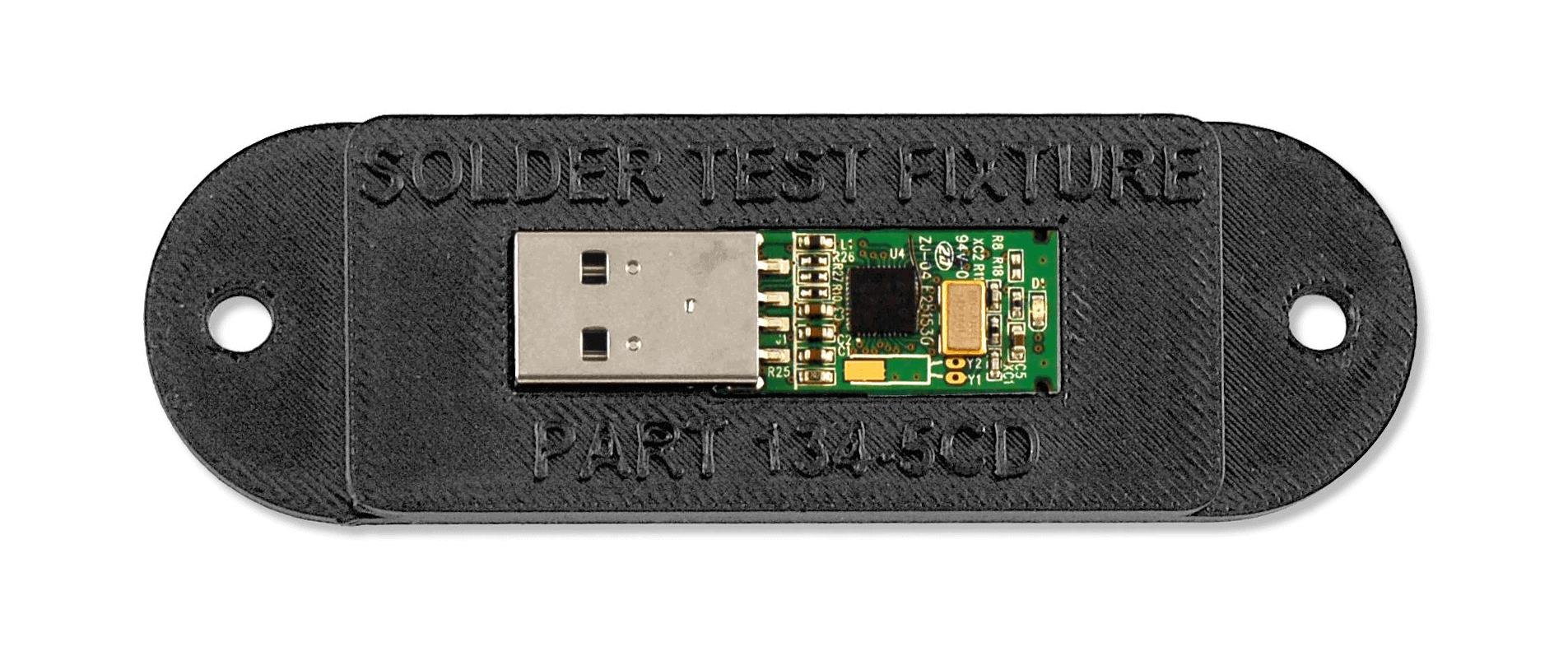

Based on FDM material ABS-M30, ABS-ESD7 prevents a buildup of static electricity for end-use components, electronic products, industrial equipment and jigs and fixtures for assembly of electronic components. ABS-ESD7 offers FDM strength on the Fortus 380mc/450mc and Fortus 900mc 3D Production Systems along with static-dissipation. Electronics manufacturers can expand the use of 3D printing onto the assembly line with this durable material that works with soluble support removal, enabling complex parts with no extra effort. Tensile strength 36 MPa (XZ Axis), Tensile modulus 2,400 MPa (XZ Axis), HDT @66 PSI 96°C, Coefficient of thermal expansion 8.825 mm/mm/°C. Download the data sheet and safety sheets here:

View the ABS-ESD7 Material Spec Sheet.

View the ABS-ESD7 Material Safety Data Sheets

John Dessoffy

Field Service Manager

Computer Aided Technology, Inc

Blog

Blog